Ladle capping transport system

A transportation system and a technology for molten iron tanks, which are applied in the field of metallurgical smelting and transportation, can solve the problems of poor transportation quality and potential safety hazards, and achieve the effects of stable operation, easy alignment, and uniform load distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

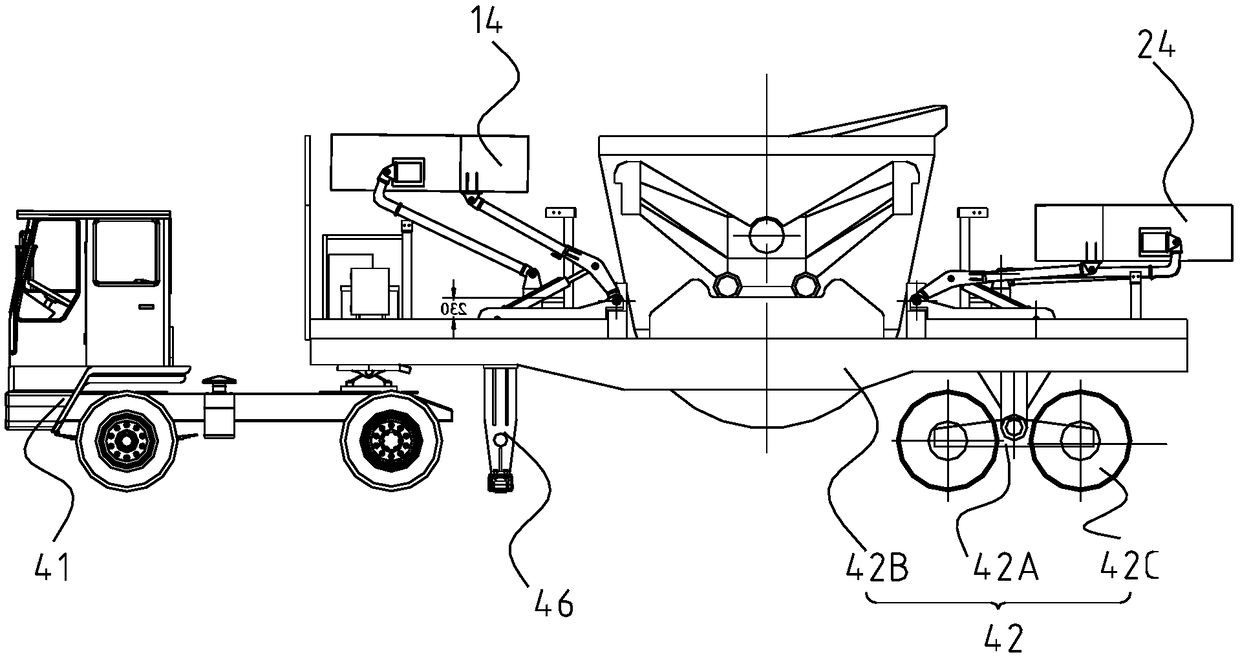

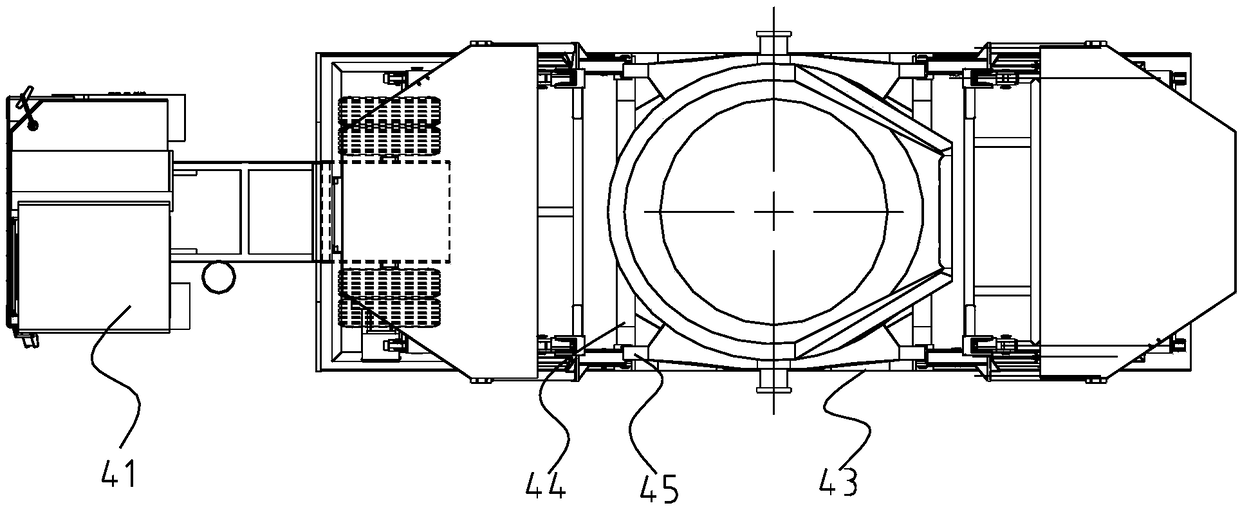

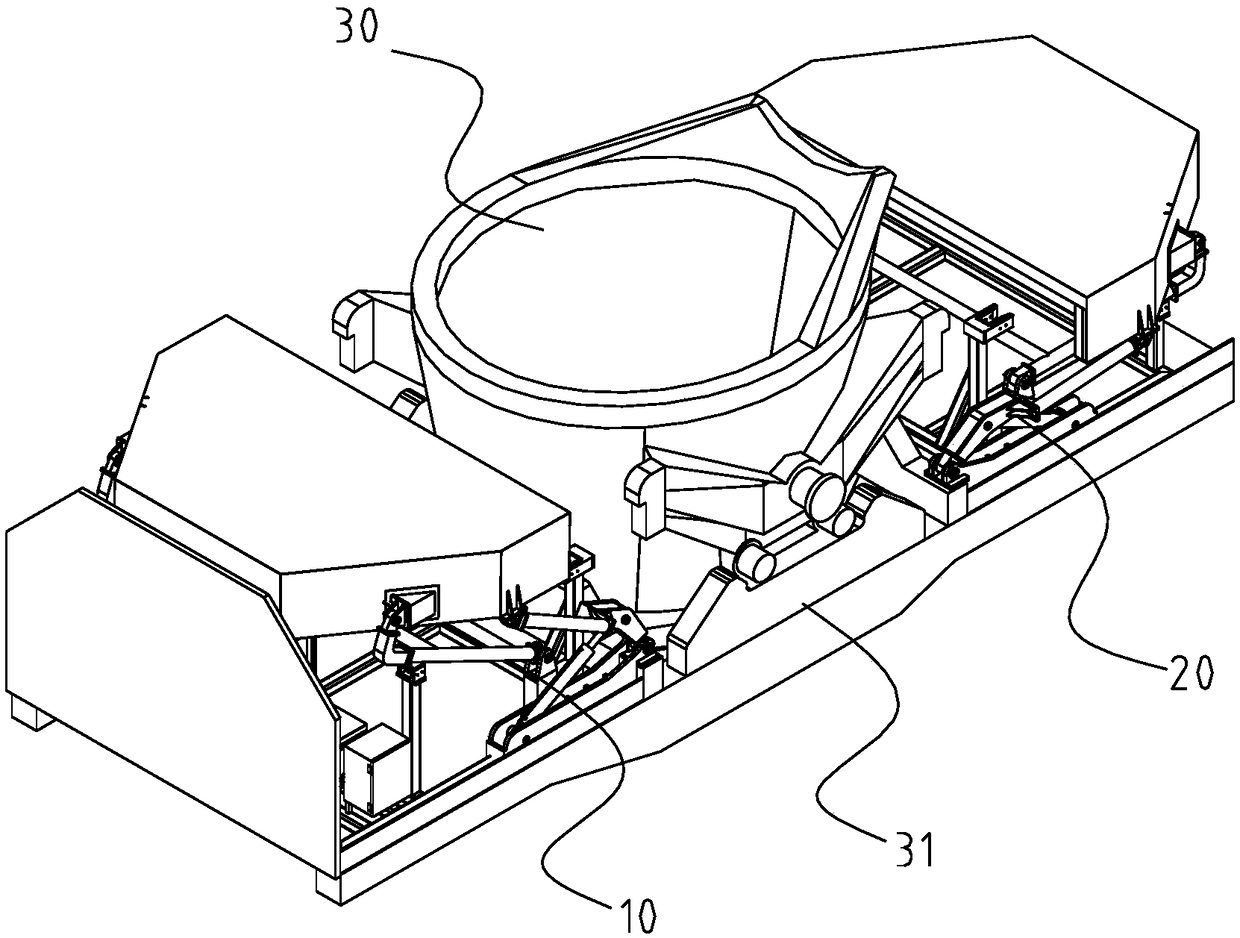

[0028] Such as figure 1 with figure 2 As shown, the present embodiment provides a molten iron tank capping transport system, comprising a transport vehicle 40 and a ladle capping device positioned on the transport vehicle, wherein the transport vehicle includes a tractor 41 and a vehicle connected with the tractor 41 Connected trailer 42, described trailer 42 comprises vehicle axle 42A, vehicle frame 42B and tire 42C, wherein said tire 42C is installed on the two ends of described vehicle axle 42A, and described vehicle axle 42A links to each other with described vehicle frame 42B, And the ladle capping device is arranged on the vehicle frame 42B, and the vehicle frame 42B is respectively provided with a crossbeam 43 and a longitudinal beam 44 along the length and width directions, and the crossbeam 43 and the longitudinal beam 44 are successively connected to form A box-type mechanism, and the box-type mechanism is located at the center of the vehicle frame 42B, positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com