Method for extracting protein from sludge by low-intensity ultrasonic enhanced enzymolysis

An ultrasonic and low-intensity technology, which is applied in the field of low-intensity ultrasonic-enhanced enzymatic sludge protein extraction, can solve the problems of low extraction efficiency of sludge protein, achieve good protein extraction effect, improve protein extraction effect, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

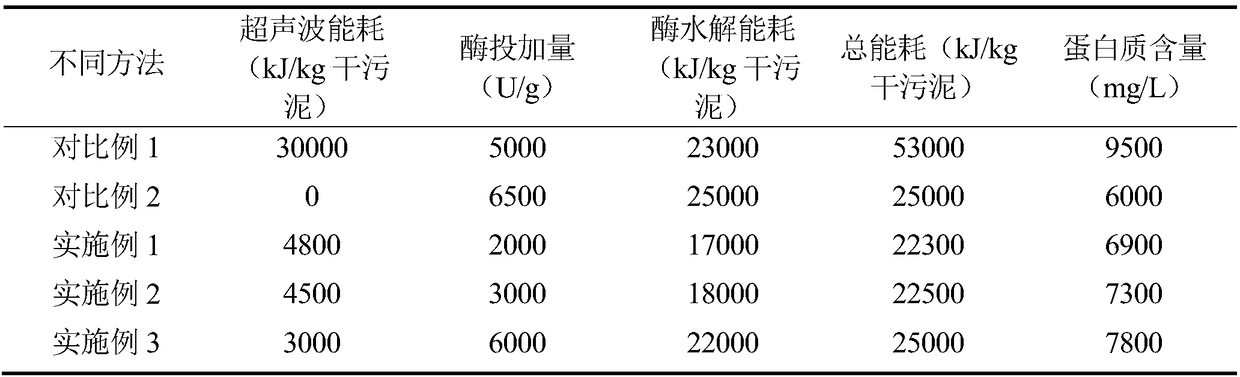

Embodiment 1

[0036] In this example, low-intensity ultrasonic waves combined with enzymatic methods are used to extract sludge protein: take sludge with a water content of 96%, put it in a 300mL beaker, add NaOH solution to adjust the pH value of the sludge to 11, and then add 2000U / g of alkaline Protease, stirred evenly and placed in the center of the ultrasonic cleaning tank; irradiated ultrasonically for 40 minutes at a sound energy density of 0.08W / mL; then placed the ultrasonically treated sludge in a constant temperature oscillator at 65°C for 2 hours; After the end, place the sludge in a boiling water bath for inactivation for 10 minutes, and then perform centrifugal filtration on the sludge after inactivation, and test the protein content in the sludge filtrate.

Embodiment 2

[0038] In this example, low-intensity ultrasonic waves combined with enzymatic methods are used to extract sludge protein: take sludge with a moisture content of 95% and place it in a 300mL beaker, add NaOH solution to adjust the pH value of the sludge to 10, and then add 3000U / g alkaline Protease, stirred evenly and placed in the center of the ultrasonic cleaning tank; irradiated ultrasonically for 25 minutes at a sound energy density of 0.15W / mL; then placed the ultrasonically treated sludge in a constant temperature oscillator at 55°C for 3.5 hours; After the reaction, the sludge was placed in a boiling water bath for inactivation for 15 minutes. After inactivation, the sludge was subjected to centrifugal filtration treatment, and the protein content in the sludge filtrate was tested.

Embodiment 3

[0040] In this example, low-intensity ultrasonic waves combined with enzymatic methods are used to extract sludge protein: take sludge with a water content of 94%, put it in a 300mL beaker, add NaOH solution to adjust the pH value of the sludge to 9, and then add 6000U / g of alkaline Protease, stirred evenly and placed in the center of the ultrasonic cleaning tank; irradiated ultrasonically for 15 minutes at a sound energy density of 0.175W / mL; then placed the ultrasonically treated sludge in a constant temperature oscillator at 45°C for 5 hours; After the end, place the sludge in a boiling water bath to inactivate for 20 minutes. After inactivation, the sludge is subjected to centrifugal filtration treatment, and the protein content in the sludge filtrate is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com