Building door and window installing structure

A technology for installing structures, building doors and windows, applied to building components, building structures, buildings, etc., can solve the problems of high air pollution, increased theft, poor security, etc., to reduce the content of harmful substances, isolate noise pollution, and quickly The effect of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described below in conjunction with the embodiments in the accompanying drawings.

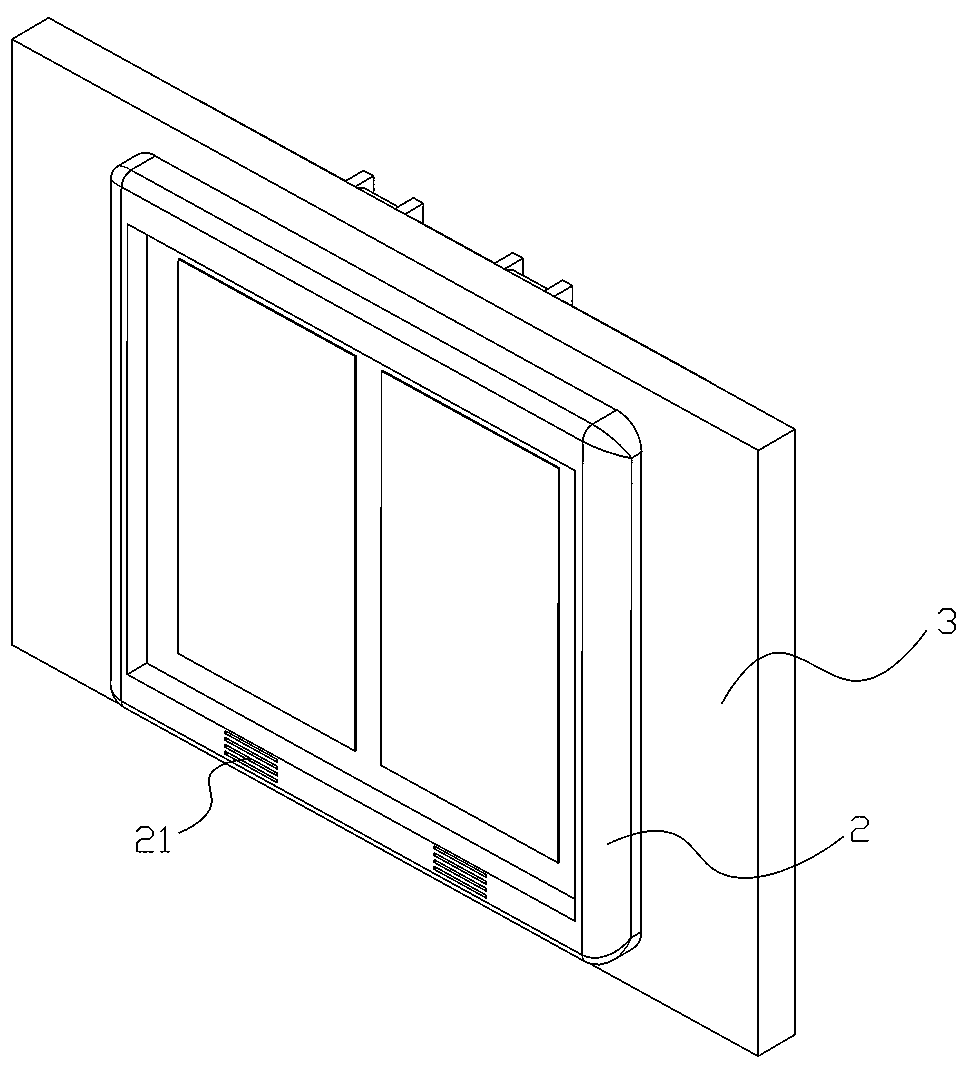

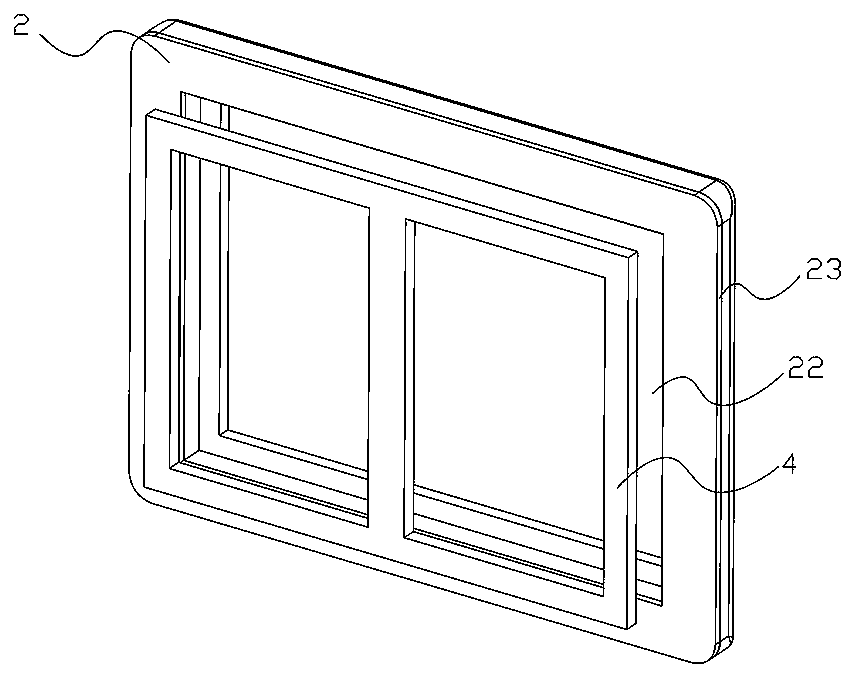

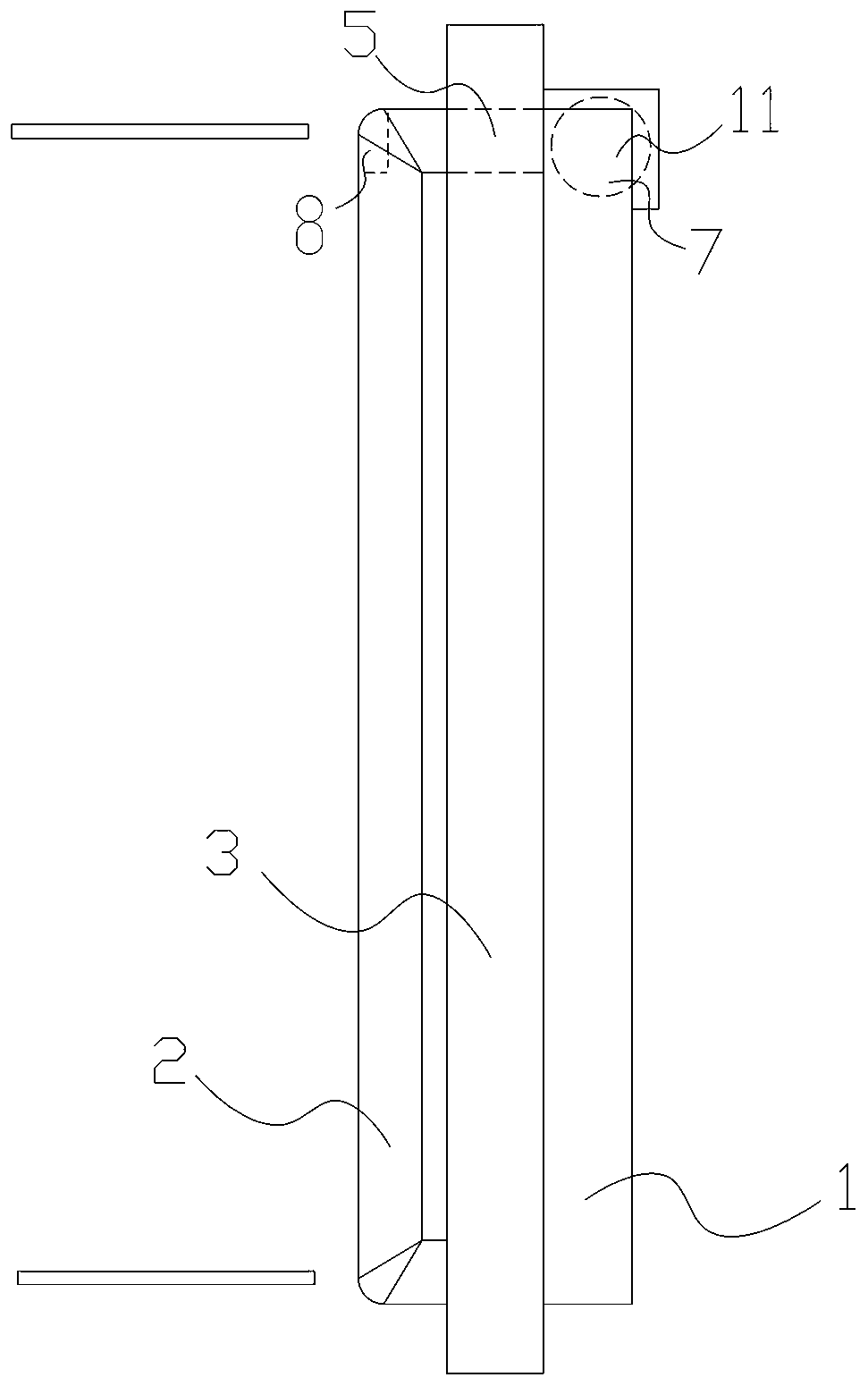

[0024] Such as Figure 1 to Figure 5 A building door and window installation structure shown includes a window 4, a frame surrounding the window 4, and a wall panel 3 for installing and fixing the frame. The frame includes an inner frame 1 and an outer frame 2, and the inner frame The body 1 is attached to the inner surface of the wall panel 3, the outer frame body 2 is attached to the outer surface of the wall panel 3, and the inner frame body 1, the outer frame body 2 and the wall panel 3 are fixed by bolts; the outer frame body 2 is close to the One side of the wallboard 3 is provided with a placement groove 22, and the window 4 is arranged in the placement groove 22; the outer side of the inner frame body 1 is provided with a first tuyere 12, and the wallboard 3, the inner frame body 1 and the outer frame body 2 are provided with through The third tuyer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com