Mine efficient filling retaining wall and construction method thereof

A construction method and retaining wall technology, which can be applied in the direction of filling, mining equipment, earth cube drilling, etc., can solve the problems of shortening the construction time, insufficient strength and firmness of the retaining wall, and unsatisfactory problems, so as to speed up the forming time and shorten the construction time. The effect of coagulation time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

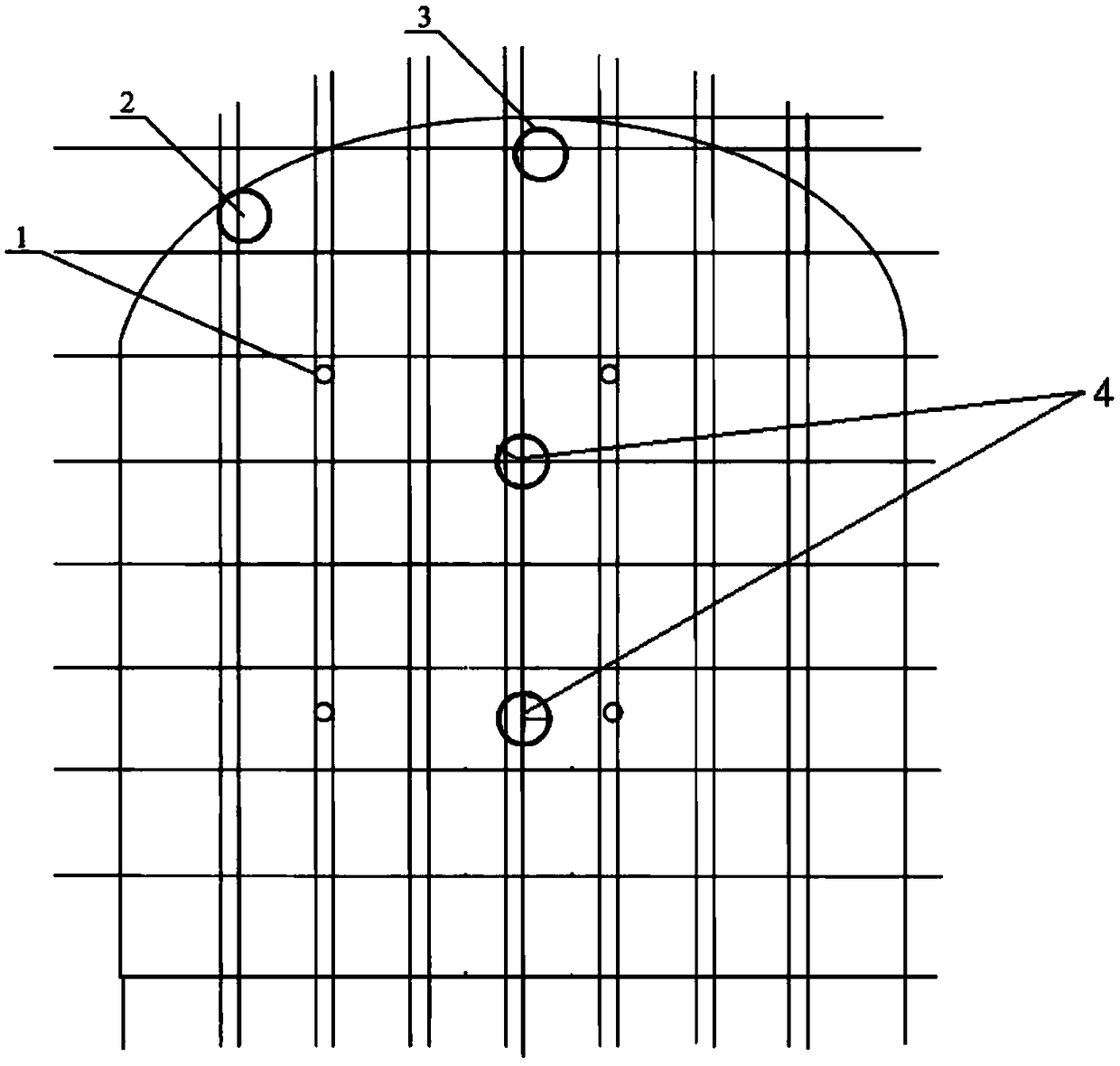

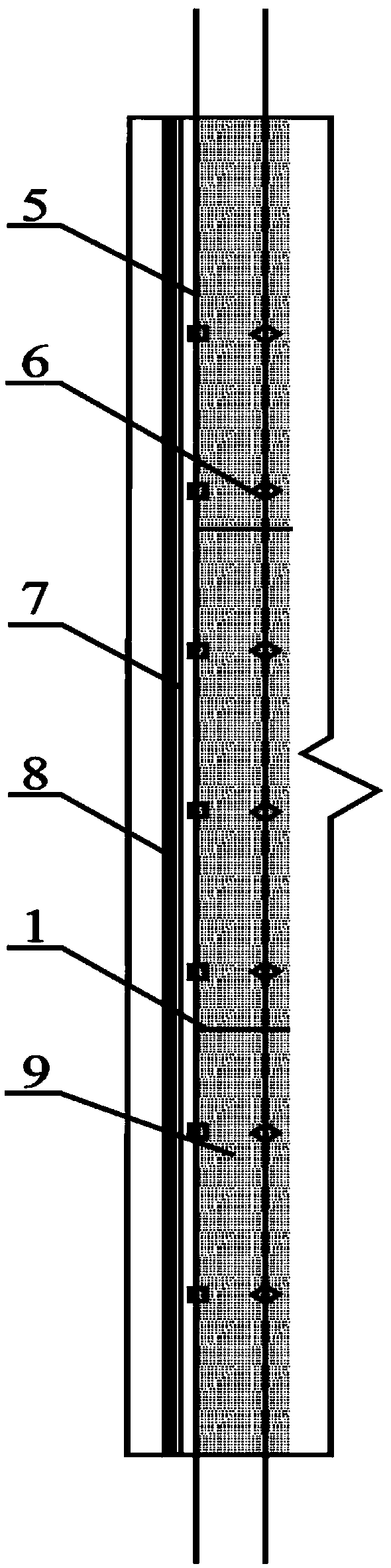

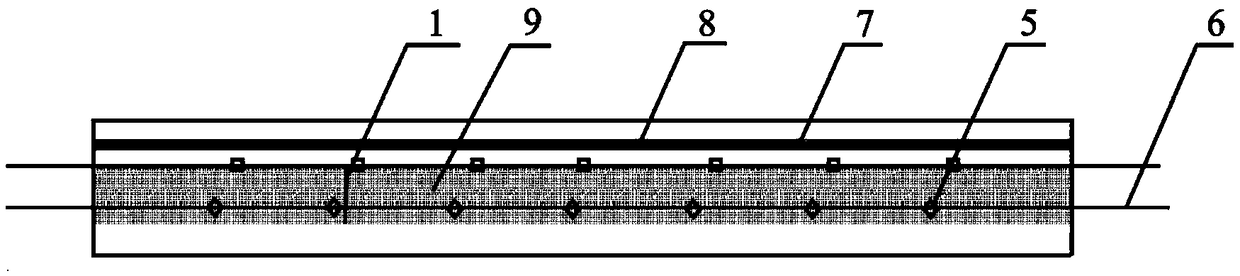

[0032] Such as Figure 1-3 As shown, a mine high-efficiency filling retaining wall includes a skeleton structure layer, a barrier layer and a concrete layer; the skeleton structure layer includes longitudinal reinforcement 5, transverse reinforcement 6, roof and metal mesh 8; the barrier layer and skeleton structure The layers are connected; the concrete layer is located in the middle of the barrier layer; the barrier layer adopts sacks 7; the concrete layer is a sprayed grout body 9; 2. The overflow pipe 3 and the water filter pipe 4; the sprayed grout thickness indicator rod 1 passes through the metal mesh 8 and is located in the concrete layer; the filling pipe 2 and the overflow pipe 3 are respectively located on the upper part of the roof and between each other There are intervals; the water filter pipe 4 is located in the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com