Laser scattering oil fume monitor

A laser scattering and monitoring instrument technology, applied in the measurement of scattering characteristics, etc., can solve the problem of unstable light intensity, achieve the effect of strong anti-pollution ability, ensure accuracy, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

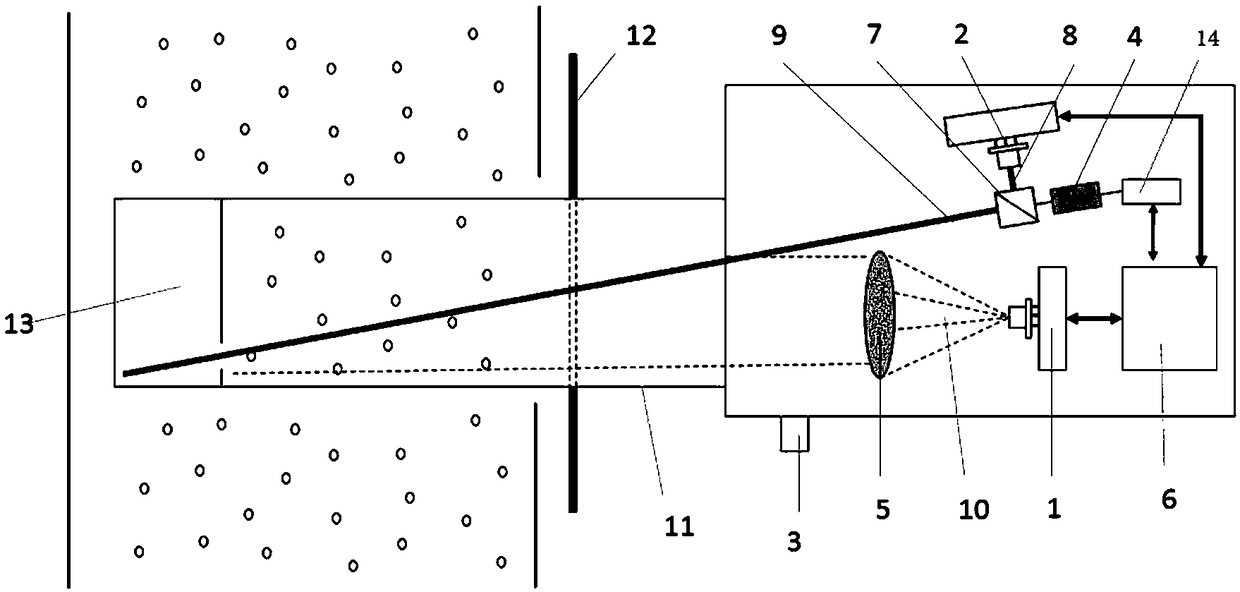

[0035] refer to figure 1 , the embodiment of the present invention proposes a laser scattering fume monitor, including a fuselage, a laser light source 4, a beam splitter 7, a first light receiver, a second light receiver 2, and an output processor 6 are arranged inside the fuselage;

[0036] Laser light source 4, used to emit laser beams;

[0037] The beam splitter 7 is used to divide the laser beam into a detection beam 9 and a correction beam 8. One end of the fuselage has an opening. When the monitor is working, the detection beam 9 is emitted from the opening;

[0038] The first light receiver is used to receive the scattered light 10 and convert the scattered light 10 into a first electrical signal, the scattered light 10 is formed by the detection beam 9 irradiating the oil fume in the exhaust pipe;

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Transmit power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com