Method and system for detecting lithium metal separation of lithium ion battery

A lithium-ion battery, detection method technology, applied in the direction of measuring electricity, measuring device, measuring electrical variables, etc., can solve the problems of low efficiency of lithium precipitation, complicated operation, etc., to improve service life and safety performance, easy and efficient operation, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

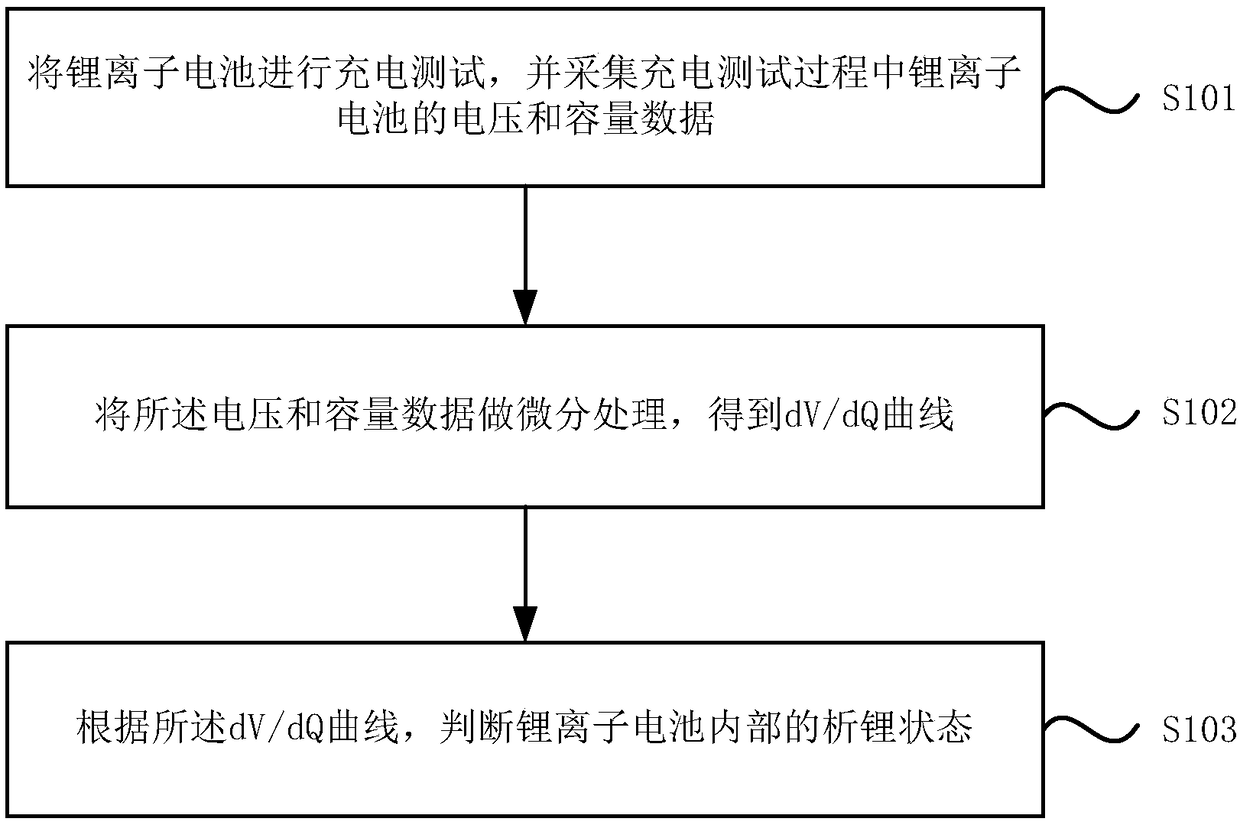

[0046] Please refer to the attached figure 1 , is a schematic flow chart of a lithium ion battery detection method provided in Embodiment 1 of the present invention. This method is suitable for the scene of lithium ion detection at the negative electrode during lithium ion charging. The method is implemented by a lithium ion battery detection system. Execution, the device can be implemented by software and / or hardware, and integrated inside the battery management platform. The method specifically includes the following steps:

[0047] S101. Perform a charging test on the lithium-ion battery, and collect voltage and capacity data of the lithium-ion battery during the charging test.

[0048] In this embodiment, the charging test of the lithium-ion battery has certain requirements on the accuracy of the equipment, for example, the voltage accuracy must be greater than or equal to 0.5‰.

[0049] It should be noted that during the charging phase of lithium-ion batteries, the pote...

Embodiment 2

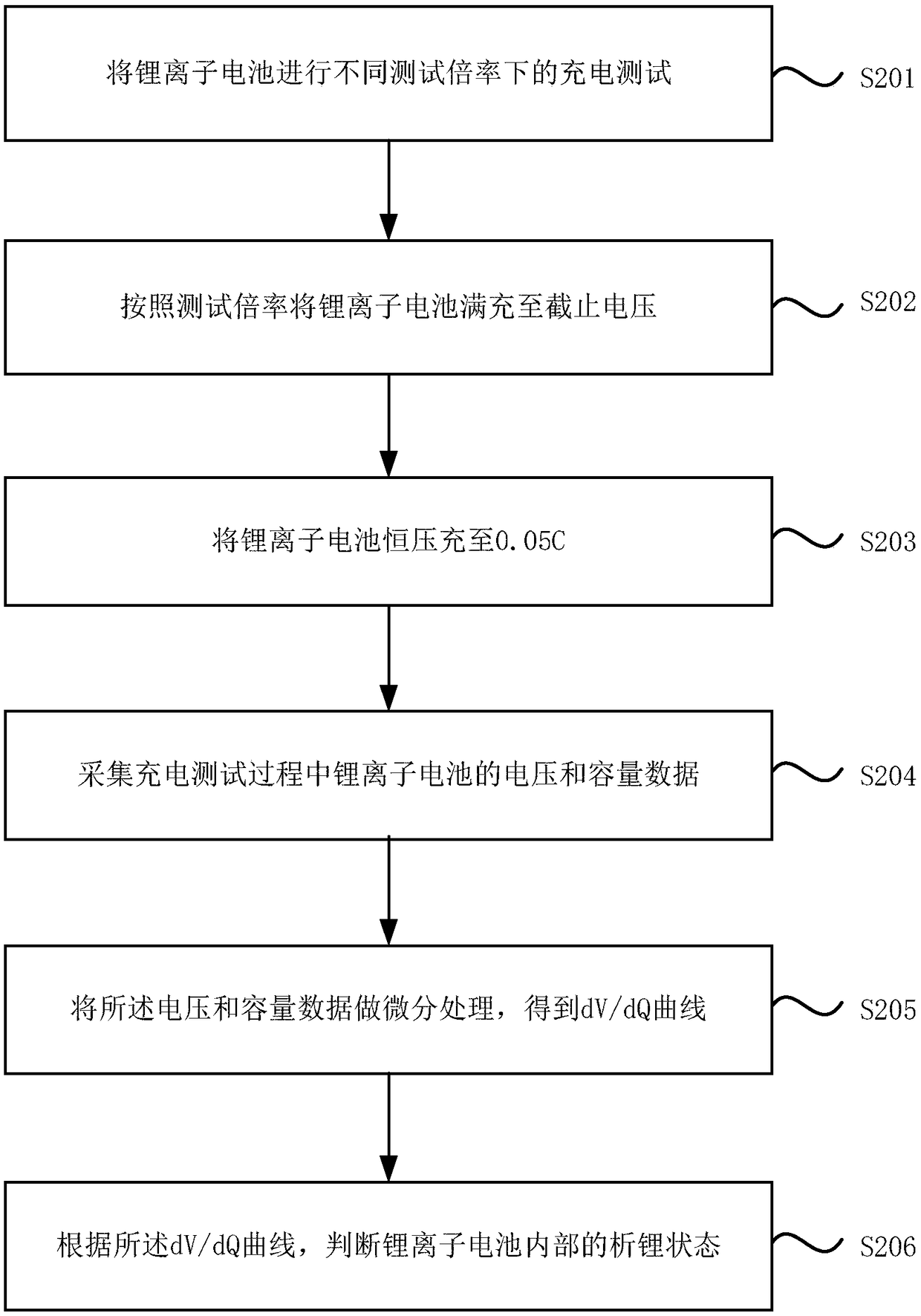

[0059] Such as figure 2 As shown, the detection method for lithium ion battery analysis provided by the second embodiment of the present invention is based on the technical solution provided by the first embodiment, the step S101 "charging the lithium ion battery is tested, and the charging test process is collected Further optimization of the voltage and capacity data of lithium-ion batteries". Explanations of terms that are the same as or corresponding to the above embodiments are not repeated here. Specifically, the following steps may be included:

[0060] The lithium-ion battery is charged under different test magnification tests;

[0061] Fully charge the lithium-ion battery to the cut-off voltage according to the test rate;

[0062] Charge the lithium-ion battery to 0.05C at a constant voltage;

[0063] Collect the voltage and capacity data of the Li-ion battery during the charging test.

[0064] Based on the above optimization, such as figure 2 As shown, the de...

Embodiment 3

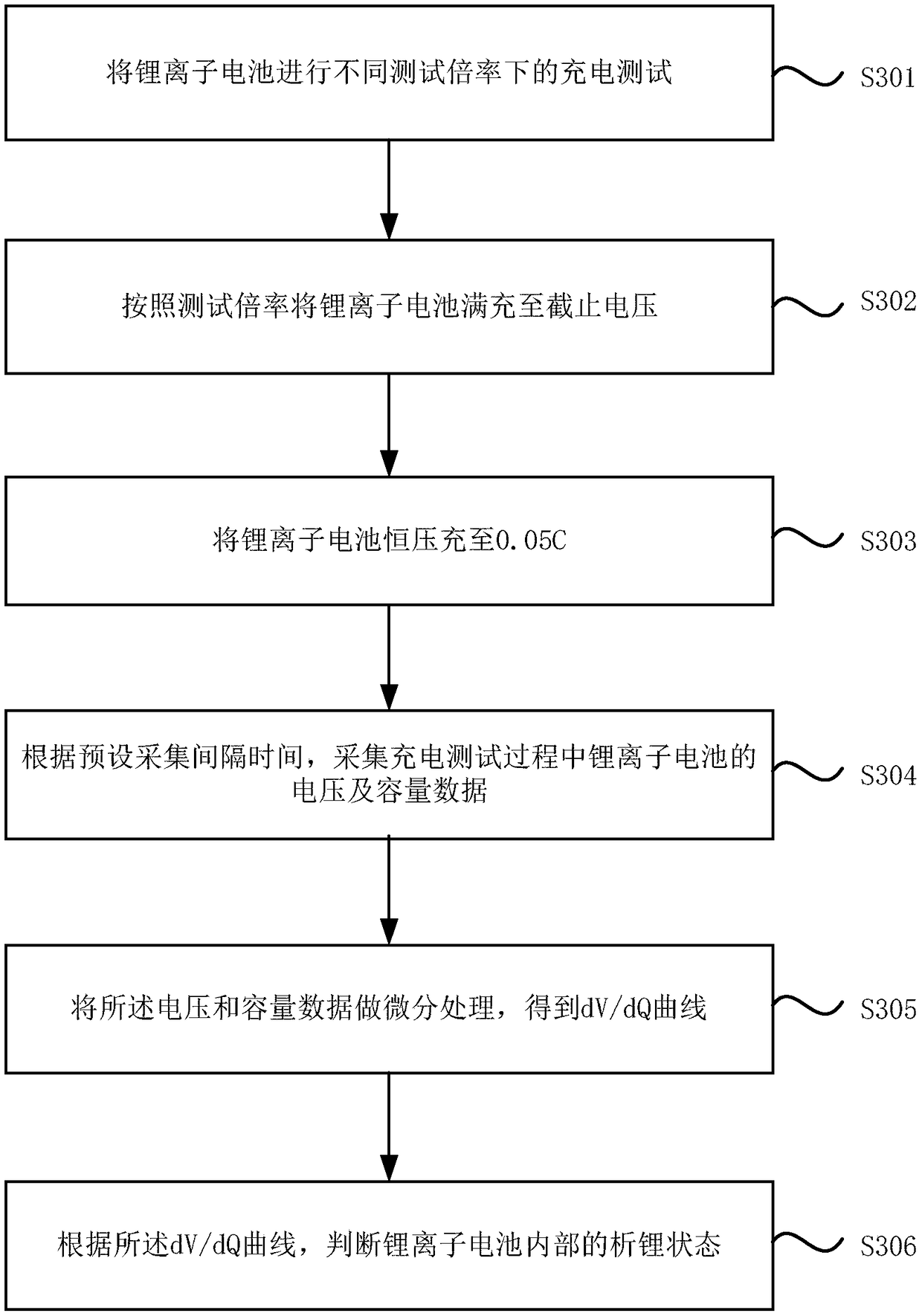

[0074] Such as image 3 As shown, the detection method for lithium ion battery analysis provided by the third embodiment of the present invention is based on the technical solution provided by the second embodiment, for step S204 "collecting the voltage and capacity data of the lithium ion battery during the charging test" further optimization. Explanations of terms that are the same as or corresponding to the above embodiments are not repeated here. Specifically, the following steps may be included:

[0075] According to the preset collection interval time, the voltage and capacity data of the lithium-ion battery during the charging test are collected; wherein, the preset collection interval time is less than or equal to 10s.

[0076] Based on the above optimization, such as image 3 As shown, the detection method for lithium ion battery analysis provided in this embodiment may include the following steps:

[0077] S301. Perform charging tests on the lithium-ion battery a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com