High-order diffraction suppression raster with large process tolerance

An advanced diffraction and latitude technology, which is applied in the field of diffractive optics, can solve the problems such as the processing precision of advanced diffraction suppression grating performance controlled primitives, and achieve the effect of being beneficial to batch processing and improving process latitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

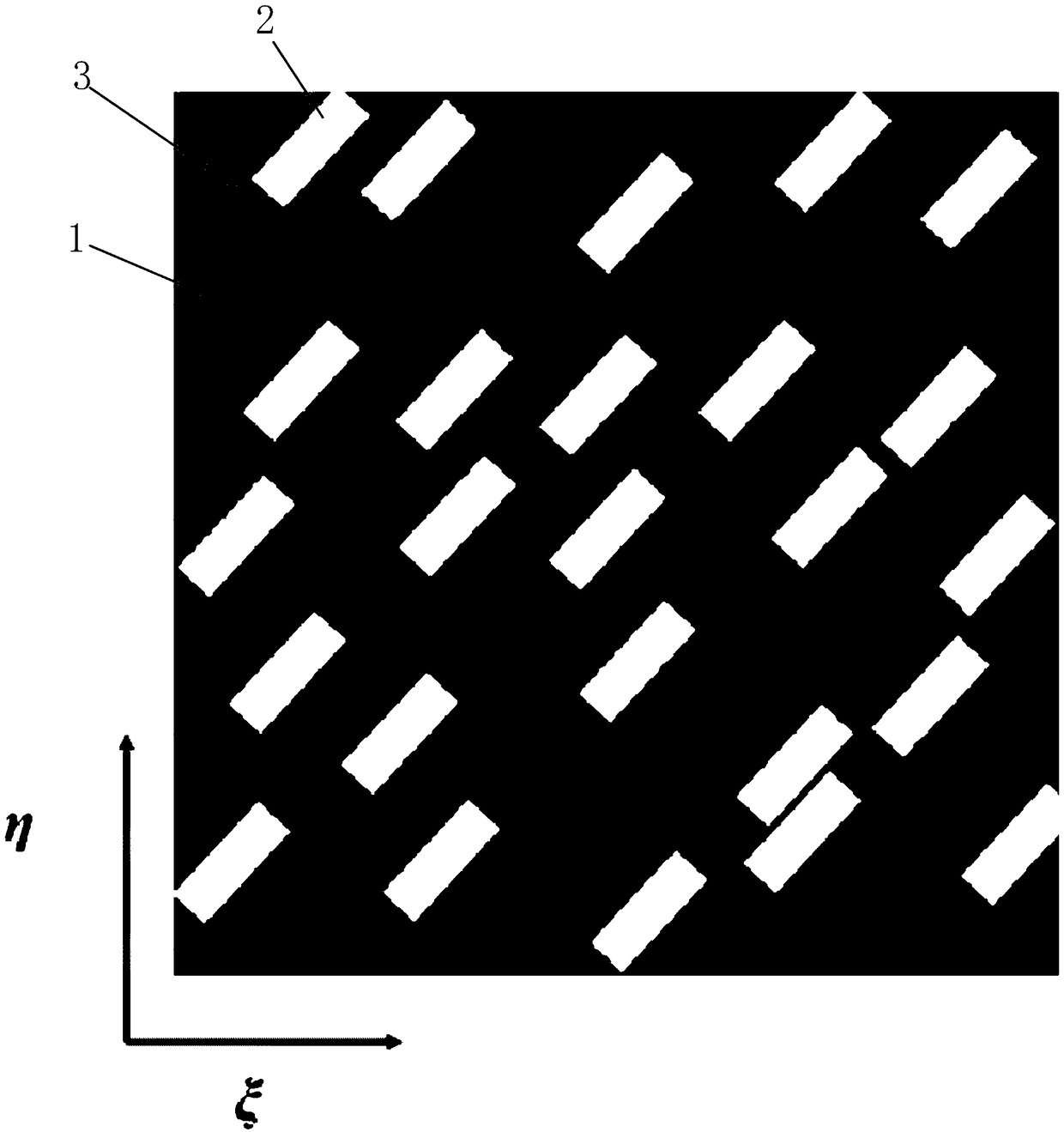

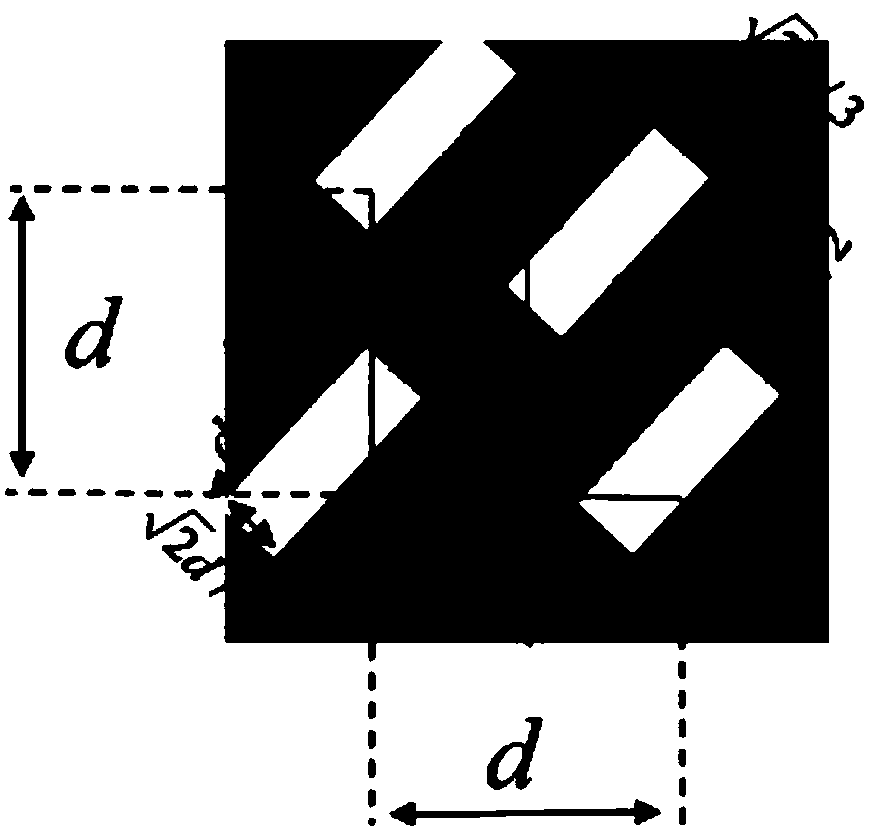

[0033] This embodiment provides an advanced diffraction suppression grating with a large process latitude in the energy range of soft X-rays. Refer to figure 1 and figure 2 . An advanced diffraction-suppressing grating with a large process tolerance, comprising an opaque substrate 1; a plurality of polygonal primitives 2 with the same shape and area and not intersecting each other are provided on the opaque substrate 1, wherein the polygonal primitives 2 are in The square lattice is quasi-randomly distributed on the opaque substrate 1 .

[0034] Specifically, a plurality of rectangular areas 3 are arranged on the opaque substrate 1, and the plurality of rectangular areas 3 are arranged periodically in a square lattice, and the period of the square lattice is d, and each rectangular area 3 has and only A polygon primitive 2 whose centers are randomly distributed within a rectangular area.

[0035] It should be noted that the embodiment of the present invention does not limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com