A Bionic Design Method for Micro-textured Turning Tool with Depth Gradient Variation

A technology of gradient change and design method, applied in the field of engineering bionics, to achieve the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

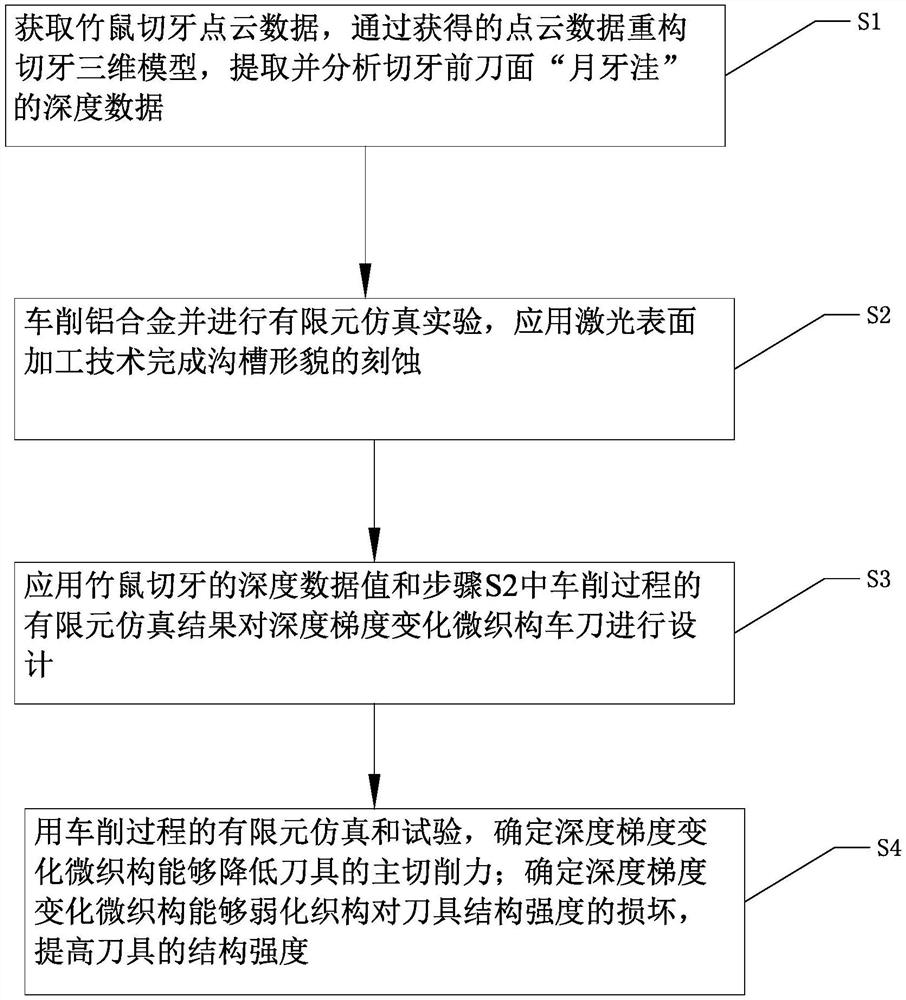

[0036] Such as Figure 1 to Figure 7 As shown, a kind of depth gradient change micro-texture turning tool bionic design method provided by the present invention comprises the following steps:

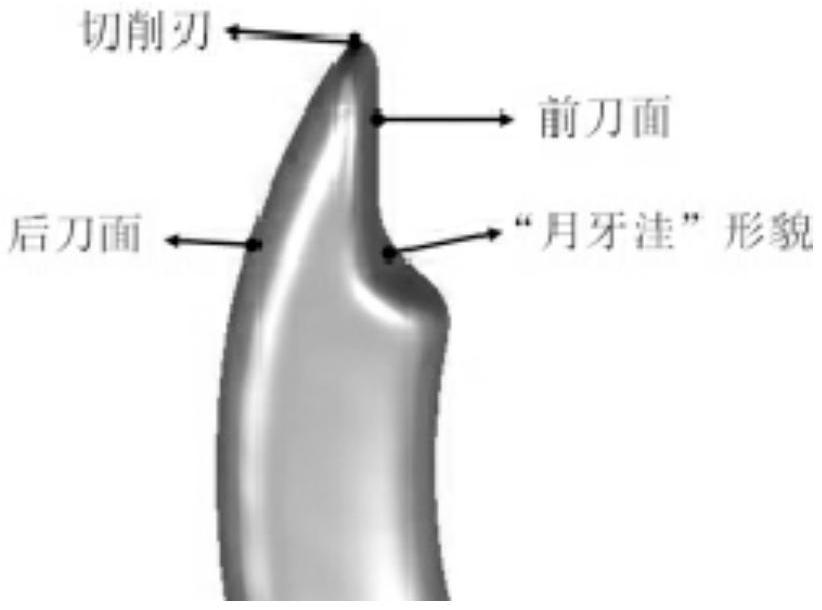

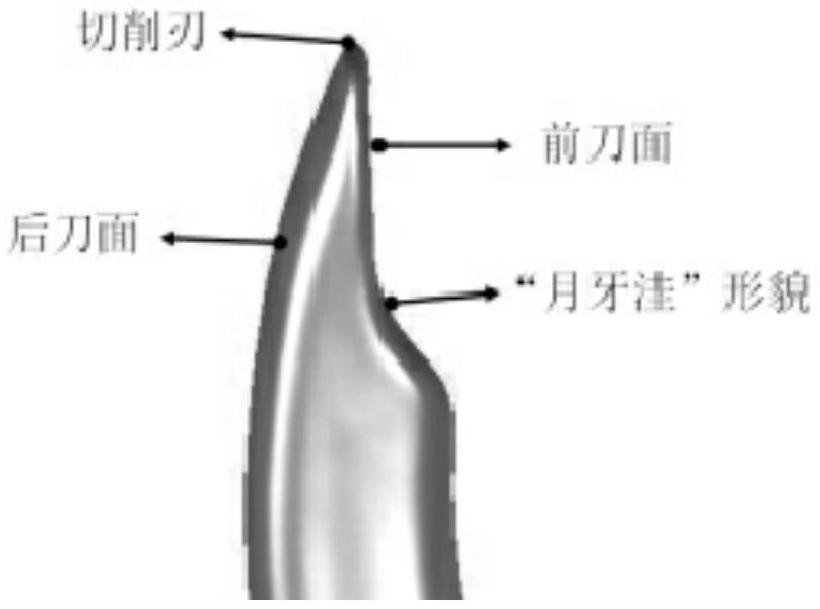

[0037] S1. Use the non-contact laser scanner EASCAN-Q to obtain the point cloud data of bamboo rat incisors, and use the reverse modeling software GEOMAGIC to process the point cloud data, and reconstruct as follows figure 1 The 3D model of the incisor shown. Based on the structure of common turning tools, the incisors are divided into three parts: rake face, flank face and cutting edge. The shape of "crescent crater" is the arc shape of the rake face of the incisor. Extracting and analyzing the depth data of "crescent crater" provides a bionic basis for the bionic design of micro-textured turning tools with depth gradient changes.

[0038] This step includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com