Vision based self-learning industrial intelligent detection system and method

An intelligent detection and self-learning technology, which is applied in the fields of instruments, biological neural network models, character and pattern recognition, etc., can solve the problems that limit the application of computer vision in the field of automation, and achieve high efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

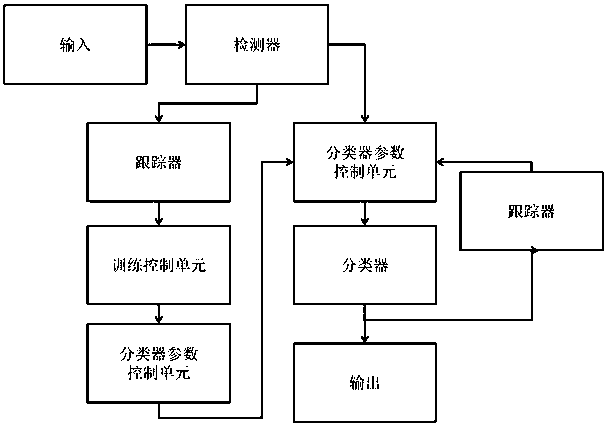

Method used

Image

Examples

Embodiment

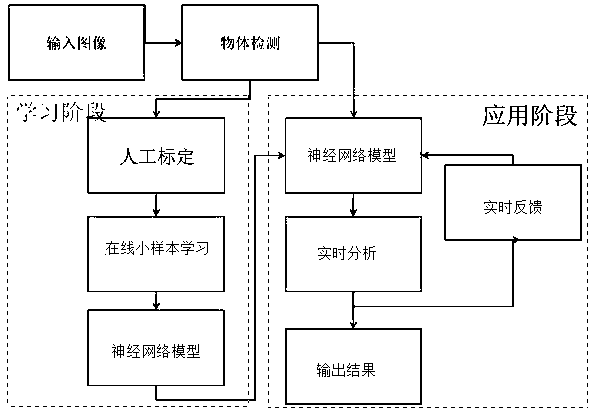

[0047] The vision-based self-learning industrial intelligent detection system is deployed after the industrial assembly line to detect the assembly line objects, distinguish the assembly line objects from the background, and detect the objects (such as printing boards, hardware, etc.) through the screen display; in the initial stage, Through the method of manual calibration, the detected objects are classified into normal objects, wrong objects and defective objects, and the object images are input into the neural network trainer for model training; when the training data reaches the minimum amount of data, the detection system is based on the training. The neural network model is used for discrimination, and according to the results, it is classified into normal objects, wrong objects and defective objects, and the results are displayed in real time. At the same time, manual calibration is performed to correct the displayed results; when the correction frequency drops to the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com