Thin-film low resistor and L-type resistor adjusting method therefor

A thin-film and L-shaped technology, which is applied in thin-film resistors, resistors, resistor manufacturing, etc., can solve the problems of thin-film low-resistance adjustment and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

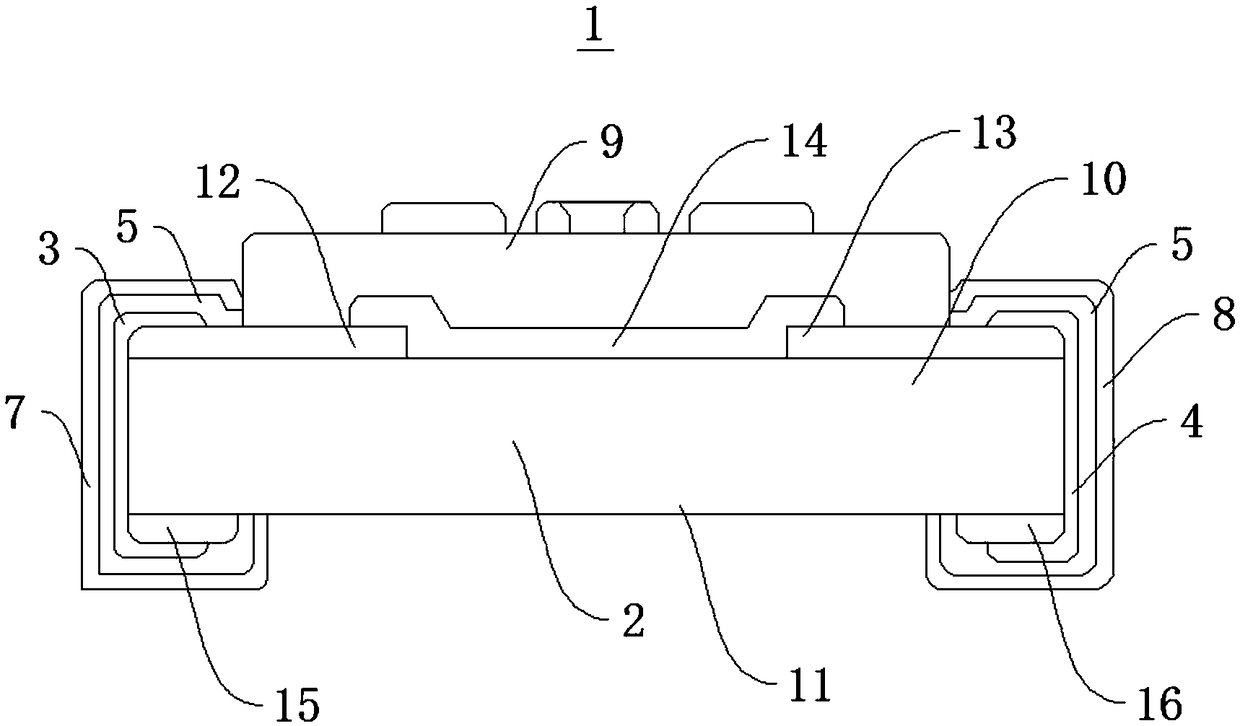

[0040] Please refer to figure 1 , the embodiment of the present invention provides a thin-film low-resistance 1, which uses a thin-film low-resistance L-type resistance adjustment method to adjust resistance.

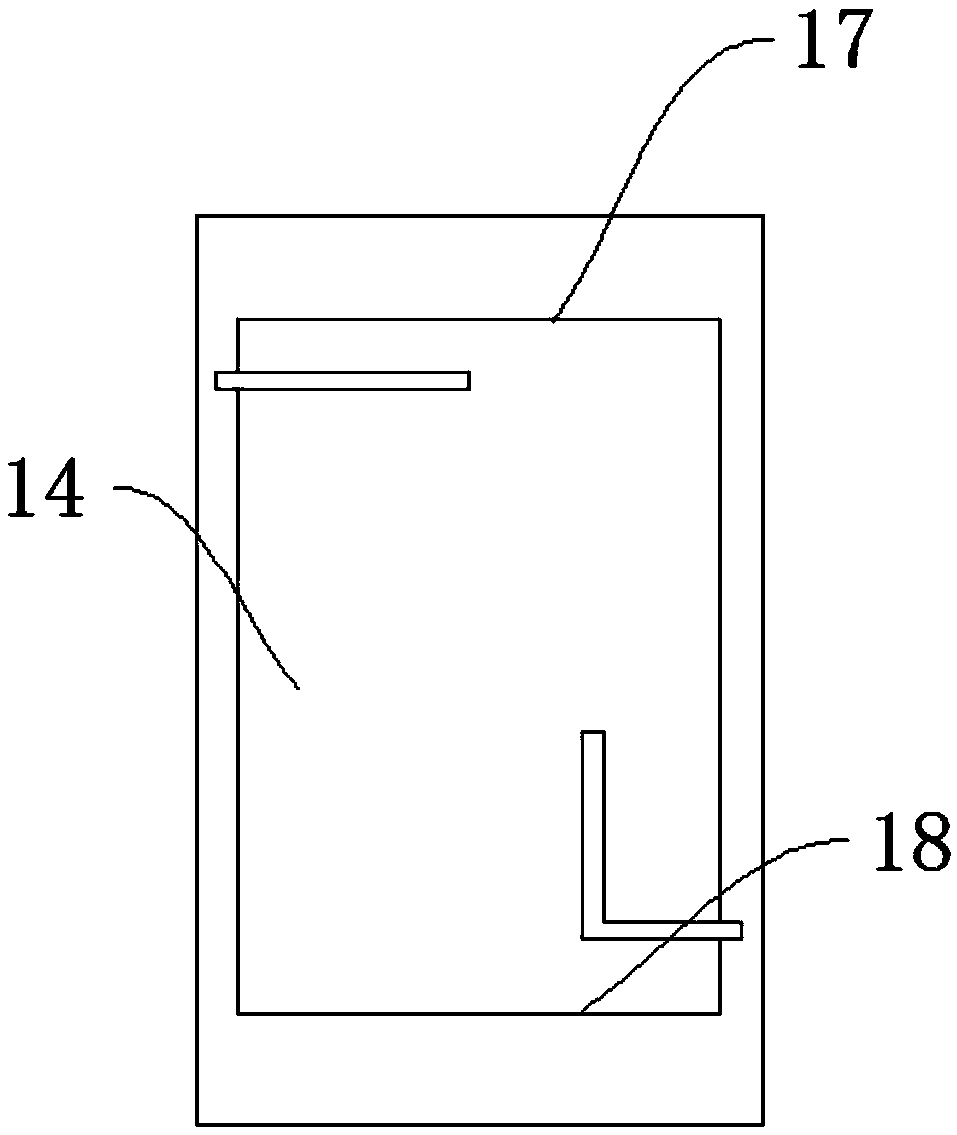

[0041] Wherein, the thin film low resistance 1 includes a ceramic substrate 2, a first end face electrode 3, a second end face electrode 4, a first metal barrier layer 5, a second metal barrier layer 6, a first solder outer layer 7, a second solder outer layer layer 8 and protective layer 9; ceramic substrate 2 has opposite first side 10 and second side 11, and first side 10, second side 11 all extend along the length direction of ceramic substrate 2; first side 10 is close to ceramic Both ends of the substrate 2 are provided with a first surface electrode 12 and a second surface electrode 13, and a resistor 14 is arranged between the first surface electrode 12 and the second surface electrode 13; The first back electrode 15 and the second back electrode 16 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com