Material strip structure used for commentator processing and method for producing copper shell by using same

A commutator and material belt technology, applied in the direction of collectors, motor generator connectors, electrical components, etc., can solve the problems of unstable feeding and affecting product quality, and achieve the effect of convenient processing, quality assurance, and stability assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

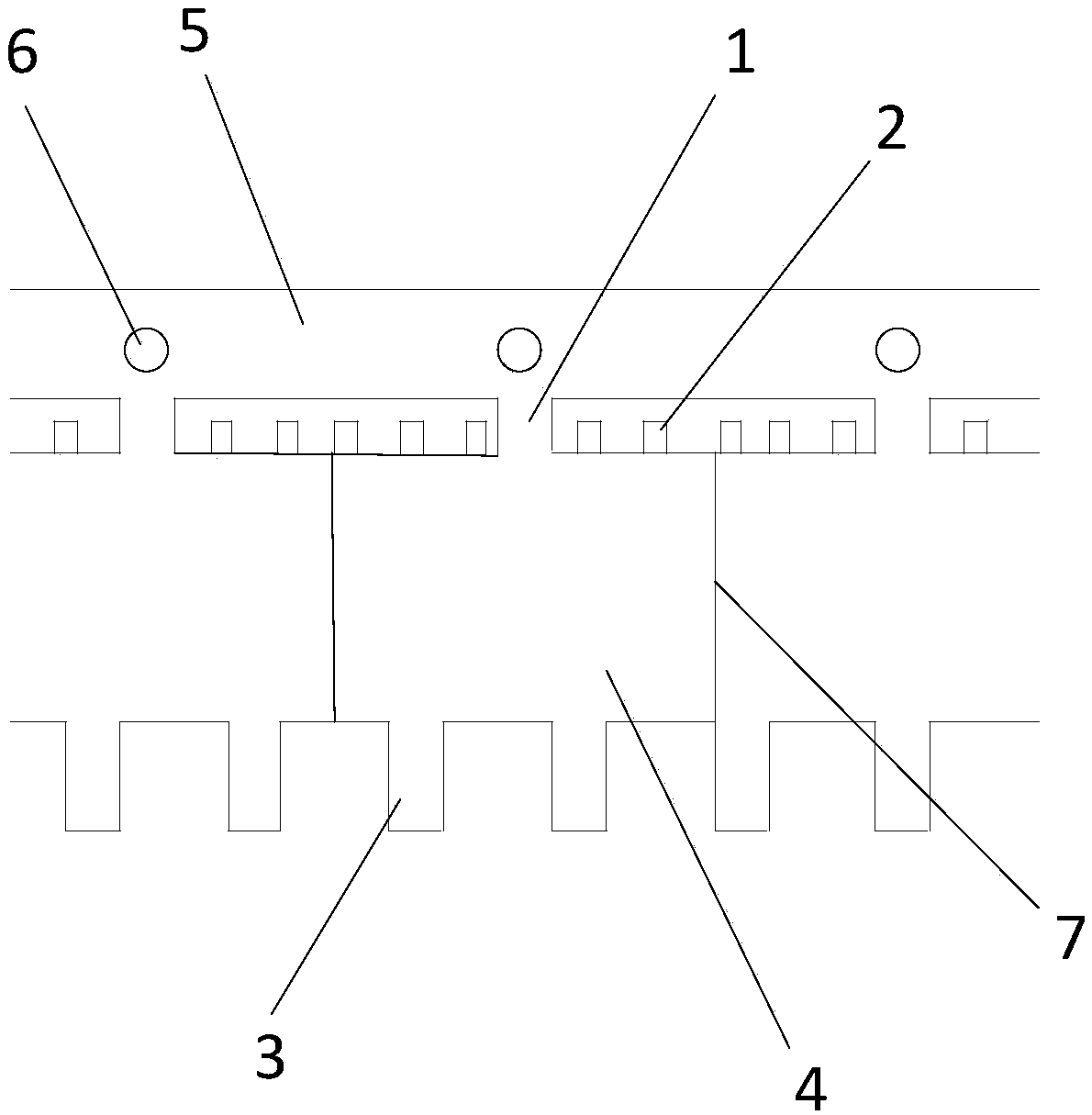

[0029] Such as figure 1 A specific embodiment of the material belt structure for commutator processing shown includes several material belt components arranged in sequence. Each of the strip components includes a lap 5 for conveying the strip structure to the next station, a strip body 4 and a first hook 1 for connecting the lap 5 and the strip body 4. Several second hook bodies 2 and third hook bodies 3 are respectively arranged on both sides of the strip body 4 perpendicular to the conveying direction, and the length of the second hook bodies 2 is less than the length of the third hook bodies 3, wherein the first A hook body 1 and a second hook body 2 are formed on the same side of the strip body 4 .

[0030] Several strip assemblies are connected through the line 7 to be cut between the strip bodies, and the setting of the line 7 to be cut is for the convenience of later cutting and separating the strip structure into several independent strip assemblies. The strip assemb...

Embodiment 2

[0039] A specific embodiment of the method for producing a copper shell using a strip structure used for commutator processing includes first cutting the copper strip into a strip structure of the required specification according to the size requirements, and at the same time cutting the copper strip into a strip structure according to a predetermined interval. One side punches and forms several positioning holes 6 . Then set the shape and position of the pre-punching cutting of the stamping and cutting equipment, that is, to remove the excess copper material except the lap 5, the strip body 4, the first hook 1, the second hook 2 and the third hook 3 , to process the strip structure into several strip assemblies arranged in sequence, and simultaneously form the line 7 to be cut between two adjacent strip structures; the edge 5 of each strip assembly passes through the first hook The body 1 is connected to the strip body 4, and several second hook bodies 2 and third hook bodies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com