Vegetable transplanting machine

A technology for transplanting machines and vegetables is applied in the field of agricultural machinery, which can solve the problems of low operation efficiency, difficult maintenance and labor, and achieve the effects of reducing the number of process operations, controlling the position accurately, and reducing soil compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

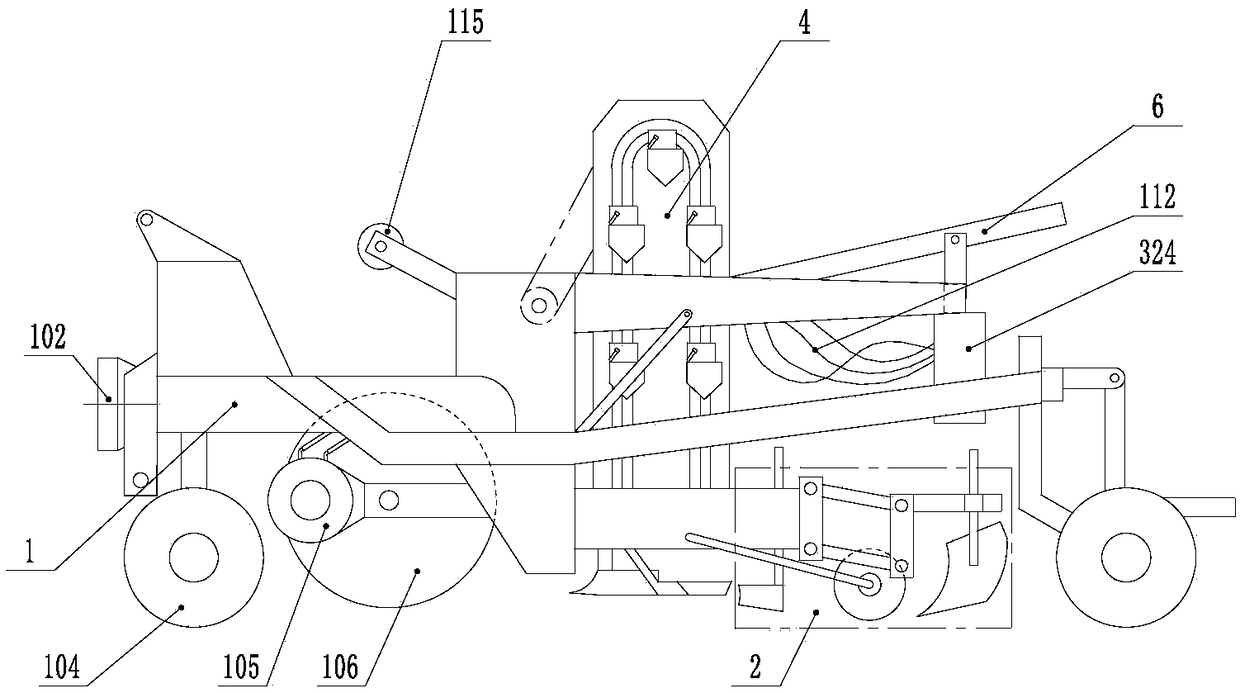

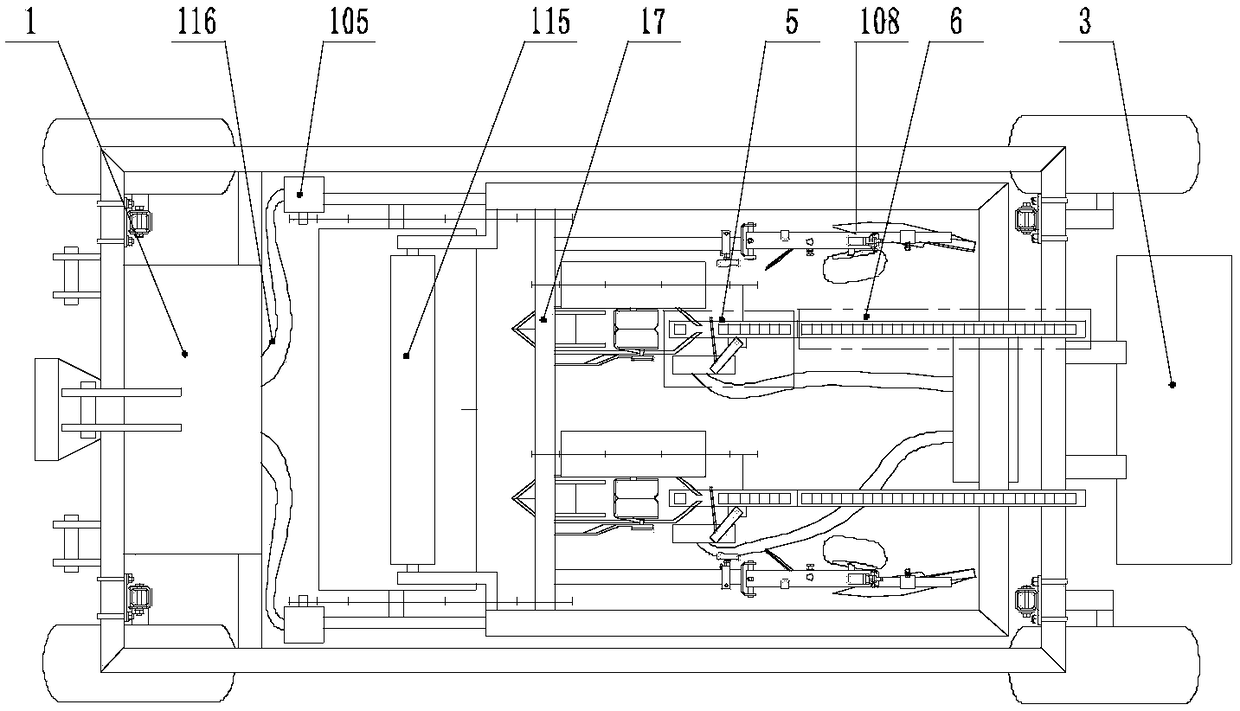

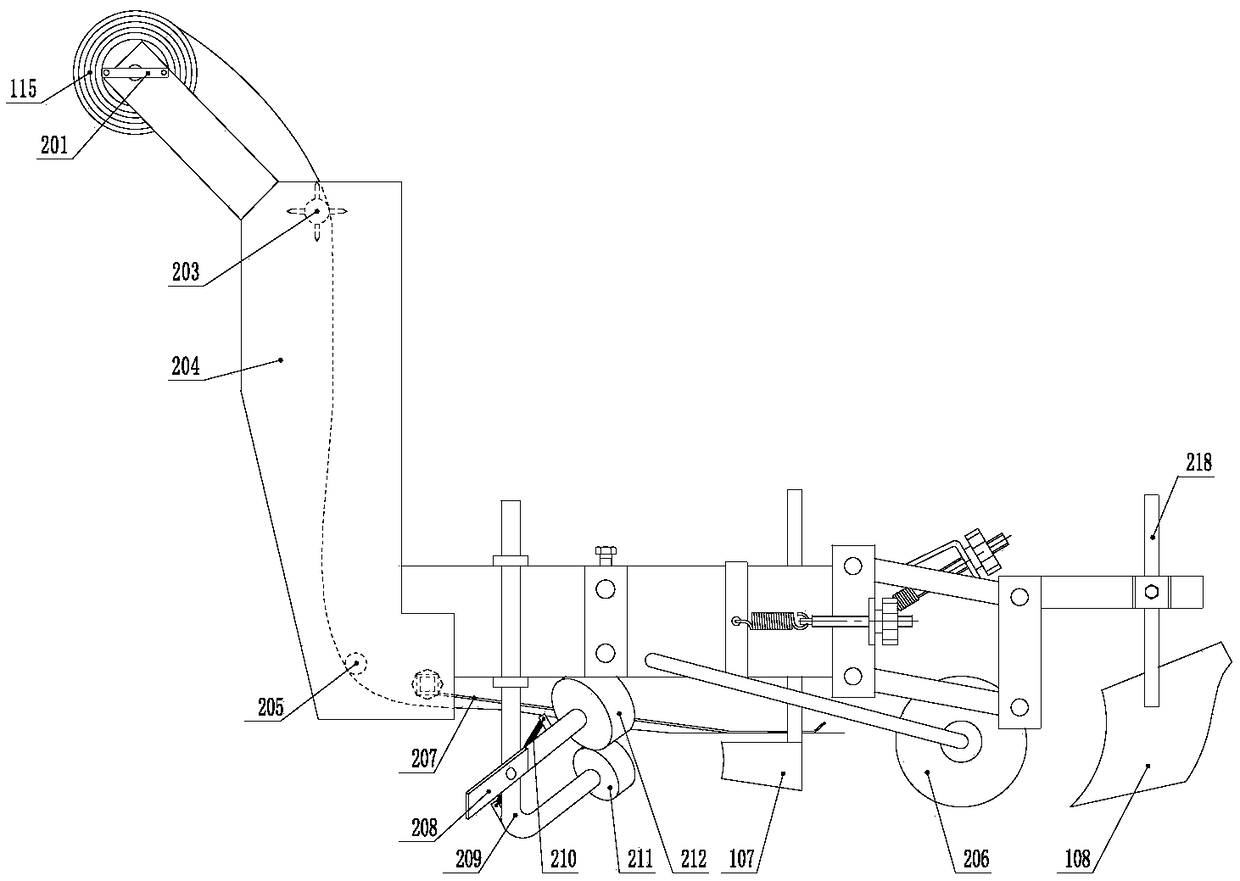

[0048] The vegetable transplanting machine of the present embodiment, as Figure 1-16 Shown, comprise the frame 1 that is articulated on the tractor and be installed on the frame 1 into row seedling conveying device 6, automatic seedling separating device 5 and planting device 4.

[0049] Such as figure 1 and figure 2 As shown, the frame 1 is provided with an intermediate shaft 17, and the power of the tractor output shaft is transmitted to the intermediate shaft 17 through the power input shaft 102 through the chain, and the intermediate shaft 17 drives the seedling discharge conveying device 6 and the automatic seedling separation device respectively. 5 actions; Automatic seedling-separating device 5 and row seedling conveying device 6 are arranged on the rear of frame 1; Planting device 4 is arranged on the front of automatic seedling-separating device 5. In this example, both the front and the rear are based on the motion direction of the rice shoots, that is, the rice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com