Semi-automatic electric-heating cooking pot

A semi-automatic, electric heating technology, which is applied in cooking utensils, utensils with integral electric heating devices, and the structure of cooking utensils, etc., can solve the problems of complexity, inhumane menu configuration and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

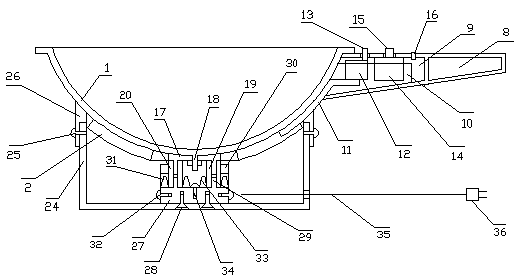

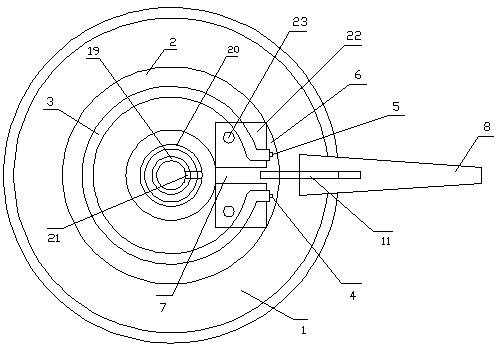

[0010] exist figure 1 , figure 2Among them, the semi-automatic electric heating cooking pot is equipped with a stainless steel pot 1, and the stainless steel pot is a traditional hemispherical stainless steel pot, and an annular electric heating plate 2 is arranged in the middle of the lower end of the stainless steel pot bottom. In order to improve heat transfer efficiency, the spherical surface of the upper end of the annular electric heating plate The spherical surface at the lower end of the stainless steel pot is closely matched by welding. There is an annular electric heating tube 3 inside the annular electric heating plate. The annular electric heating tube is provided with a front wiring pile 4 and a rear wiring pile 5. Alloy casting molding, a half-moon notch 6 is set on the right side of the annular electric heating plate, and the front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com