Method for separation and purification of cynarin and chlorogenic acid in cynara scolymus by simulated moving bed chromatography

A technology of simulating moving bed, separation and purification, applied in the field of extraction and purification of effective components of natural plants, to achieve the effect of simple treatment process, large treatment capacity and reduction of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

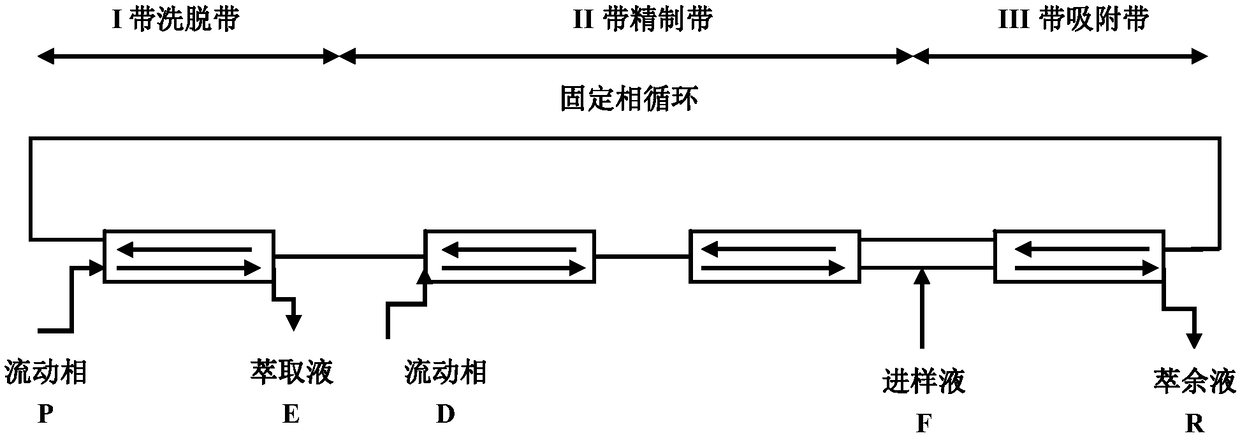

Method used

Image

Examples

Embodiment 1

[0039] 1) Artichoke leaves were dried at 60°C for 12 hours, crushed, passed through a 10-20 mesh sieve, and then refluxed with 5 times the amount (mass volume ratio) of 70% ethanol for 3 times, each time for 3 hours, combined extracts, and reduced pressure After concentrating to a relative density of 1.10, add water for water precipitation, filter to remove insoluble matter, and obtain artichoke leaf extract;

[0040] 2) The artichoke leaf extract obtained in step 1) is processed by macroporous resin column chromatography: select D-101 macroporous adsorption resin, load the sample with a volume flow rate of 2BV / h, use 2BV of 1.0wt%NaOH Aqueous solution to elute impurities, wash with 3.5BV of water to neutrality, elute cynaric acid and chlorogenic acid with 5BV of 75% ethanol, the flow rate of mobile phase is 1BV / h; obtain the crude extract, the volume of ethanol in the crude extract Content > 85%;

[0041] 3) The crude extract is distilled under reduced pressure at 50°C, conc...

Embodiment 2

[0054] 1) Artichoke leaves were dried at 60°C for 12 hours, crushed, passed through a 10-20 mesh sieve, and then refluxed with 10 times the amount of 70% ethanol to extract 3 times, each time for 3 hours, combined extracts, concentrated under reduced pressure to a relative density of After 1.10, add water for water precipitation, filter to remove insoluble matter, and obtain artichoke leaf extract;

[0055] 2) The artichoke leaf extract obtained in step 1) is processed by macroporous resin column chromatography: select D-101 macroporous adsorption resin, load the sample with a volume flow rate of 2BV / h, use 1BV of 1.5wt%NaOH Aqueous solution to elute impurities, wash with 3.5BV of water to neutrality, elute cynaric acid and chlorogenic acid with 5BV of 75% ethanol, the flow rate of mobile phase is 1BV / h; obtain the crude extract, the volume of ethanol in the crude extract Content > 85%;

[0056] 3) The crude extract is distilled under reduced pressure at 50°C, concentrated by...

Embodiment 3

[0069] 1) Artichoke leaves are dried at 60°C for 12 hours, crushed, passed through a 10-20 mesh sieve, and then refluxed with 8 times the amount of 80% ethanol for 2 times, each time for 3 hours. The extracts are combined and concentrated under reduced pressure until the relative density is After 1.10, add water for water precipitation, filter to remove insoluble matter, and obtain artichoke leaf extract;

[0070] 2) The artichoke leaf extract obtained in step 1) is processed by macroporous resin column chromatography: select AB-8 macroporous adsorption resin, load the sample with a volume flow rate of 2BV / h, use 1BV of 1.5wt%NaOH Aqueous solution to elute impurities, wash with 3.5BV of water to neutrality, elute cynaric acid and chlorogenic acid with 5BV of 75% ethanol, the flow rate of mobile phase is 1BV / h; obtain the crude extract, the volume of ethanol in the crude extract Content > 85%;

[0071] 3) The crude extract is distilled under reduced pressure at 50°C, concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com