Assembly type ballastless track slab

A ballastless track and assembled technology, applied in the field of rail transit, can solve problems such as poor repairability, poor ballastless track adjustment ability, inconvenient manufacturing, transportation, construction, and maintenance, so as to reduce the difficulty of replacement and maintenance and make the factory The effect of reducing the difficulty of prefabrication and enhancing the repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

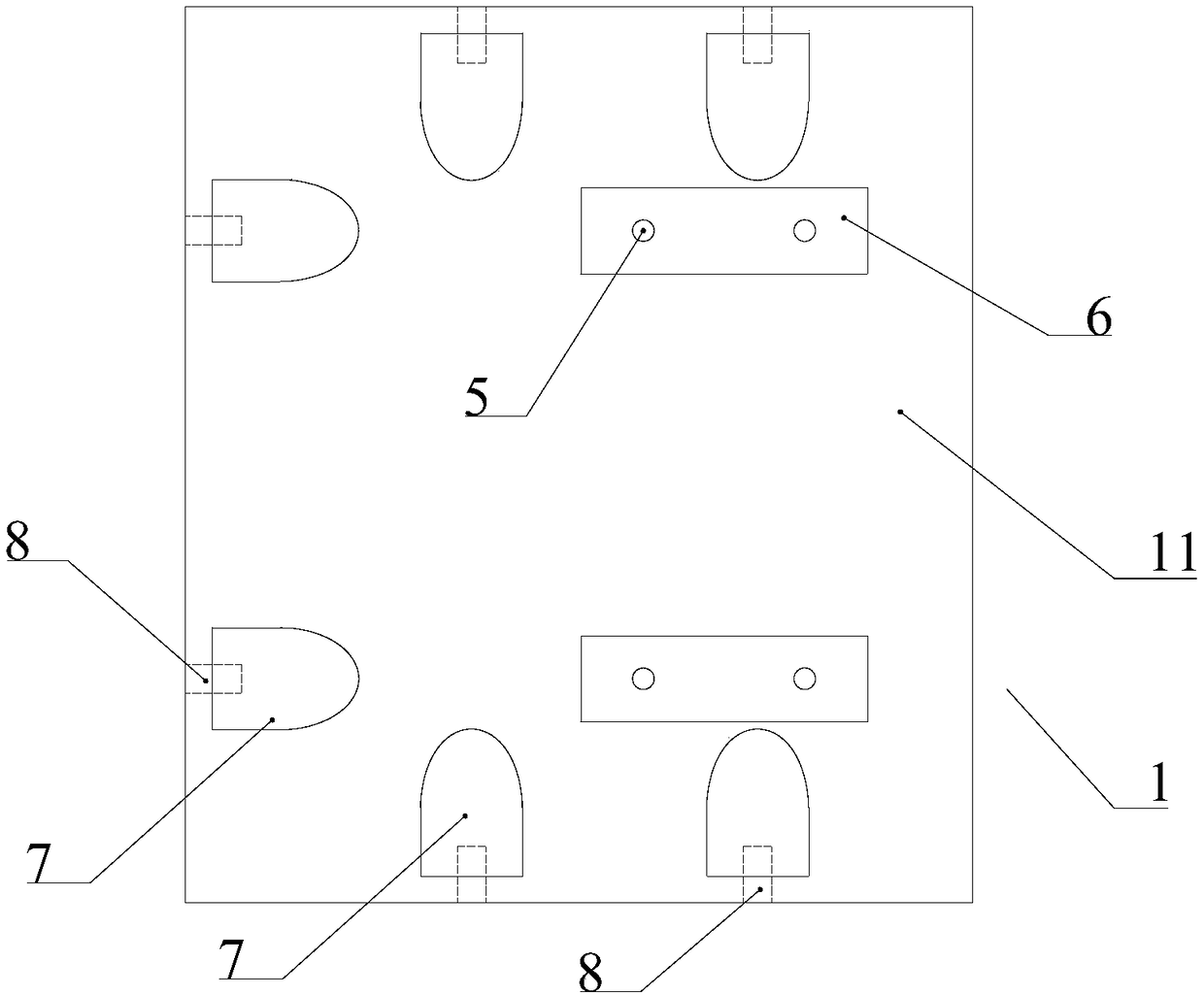

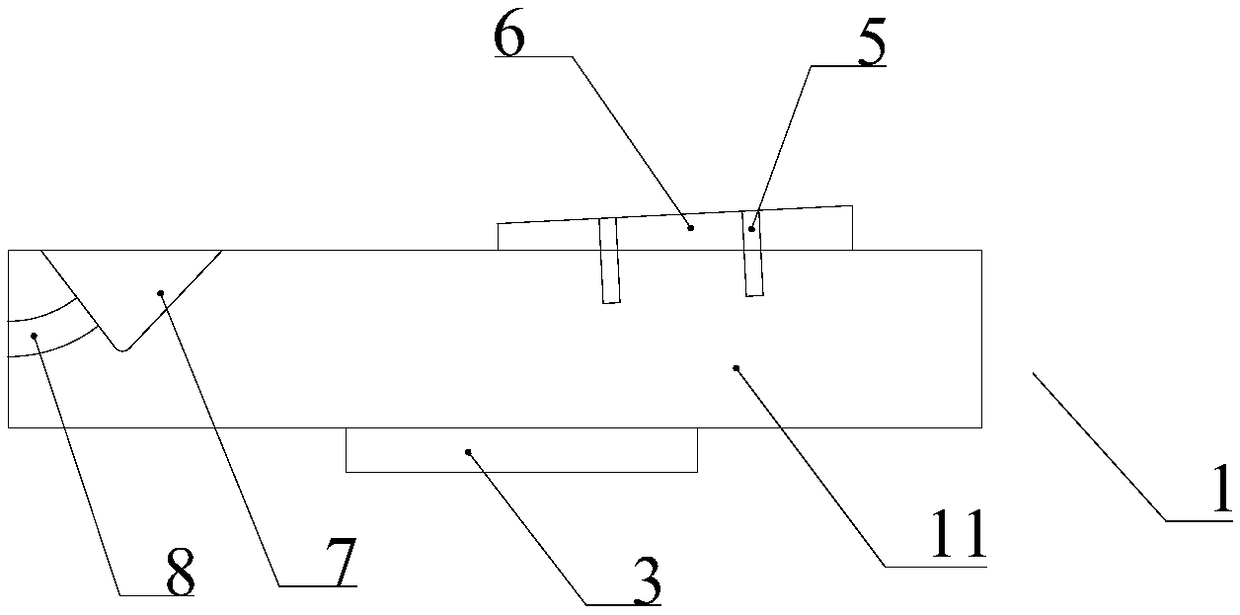

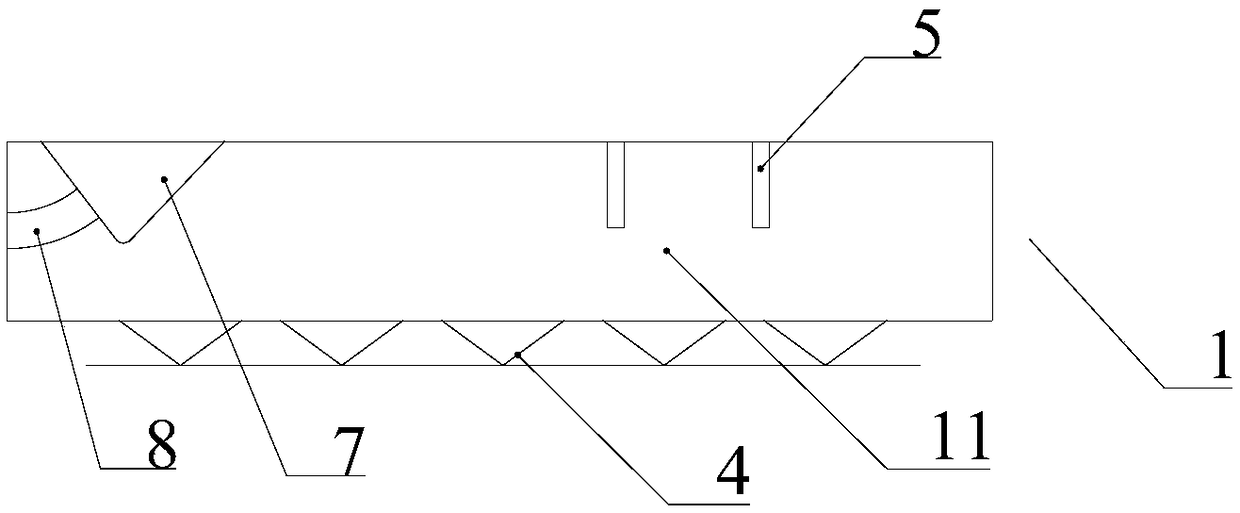

[0042] Such as Figure 1-Figure 3 As shown, an assembled ballastless track unit plate includes a unit plate body 11, several installation chambers 7 preset on the unit plate body 11, and reserved on the unit plate body 11 There are several connecting channels 8 , each of the installation chambers 7 communicates with one of the connecting channels 8 . The installation chamber 7 is a recessed open-air hole reserved on the unit board body 11, the connecting channel 8 is located inside the unit board body 11, and one end opening of the connecting channel 8 is located in the installation chamber 7 , the other end passes through the unit board body 11 , and the opening is located on the side of the unit board body 11 . In order to realize connection with adjacent unit boards, the installation chamber 7 and the corresponding connecting channel 8 are located at least two edges of the unit board body 11 .

[0043] The shape of the unit plate body 11 is rectangular or wedge-shaped, an...

Embodiment 2

[0046] Such as Figure 4-Figure 5 As shown, an assembled ballastless track slab includes several unit plates 1 assembled into a track slab, and a connecting mechanism 2 connecting the unit slabs 1, wherein, along the transverse direction of the track slab, at least two mutually connected The unit plate 1, and also includes at least two interconnected unit plates 1 along the longitudinal direction of the track plate. The shape of the unit plate 1 is rectangular or wedge-shaped, and the unit plate 1 may include various sizes. Such as Figure 11 As shown, all the unit plates 1 form a continuous track plate structure.

[0047] The unit plate 1 is pre-embedded with connecting steel bars 3 for connecting with the substructure. The unit plate 1 is also provided with a rail platform 6, and both the unit panel 1 and the rail platform 6 are preset with fastener installation holes 5, and the fastener system is installed on the rail platform 6, and through the rail platform 6 can real...

Embodiment 3

[0050] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the unit plate 1 is not provided with a rail support platform 6, and the fastener system is directly installed on the unit 1, and the rail bottom slope is realized through the fastener system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com