Assembly type ballastless track system

A ballastless track and assembled technology, applied in the field of rail transit, can solve the problems of the ballastless track system due to the damage of the lower foundation, the laying and development obstacles of the ballastless track, and the normal operation of the rail transit, so as to enhance the adjustment ability and reliability The effect of repairing ability, reducing the amount of building materials, and reducing the workload of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in combination with test examples and specific implementations. However, it should not be understood that the scope of the above-mentioned subject of the present invention is limited to the following embodiments, and all technologies implemented based on the content of the present invention belong to the scope of the present invention.

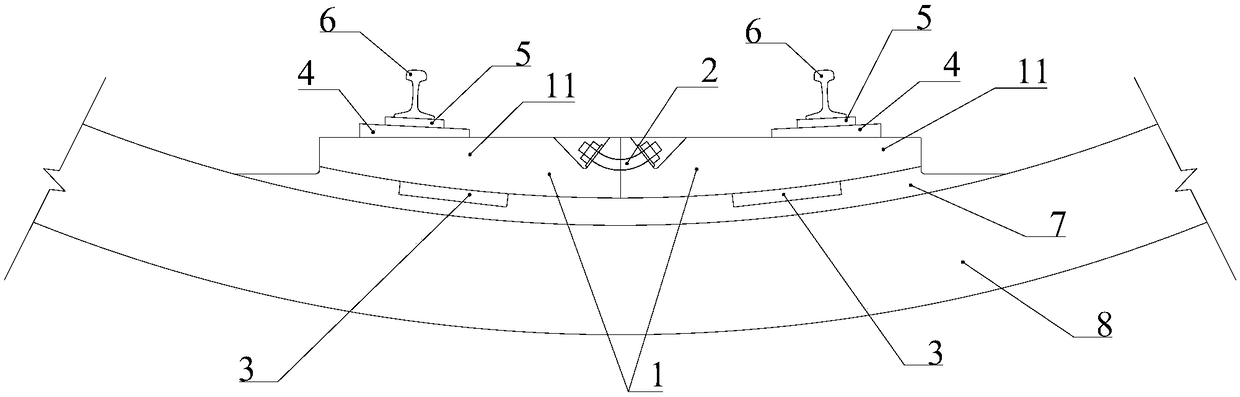

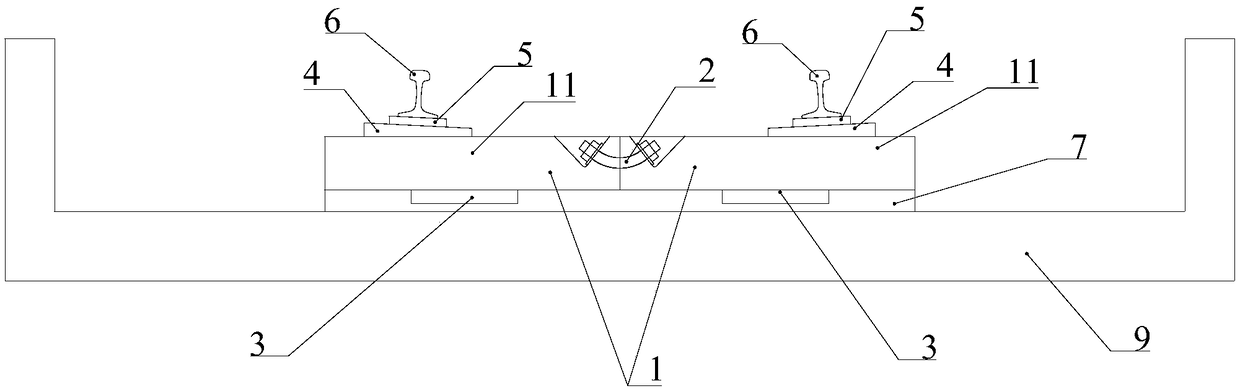

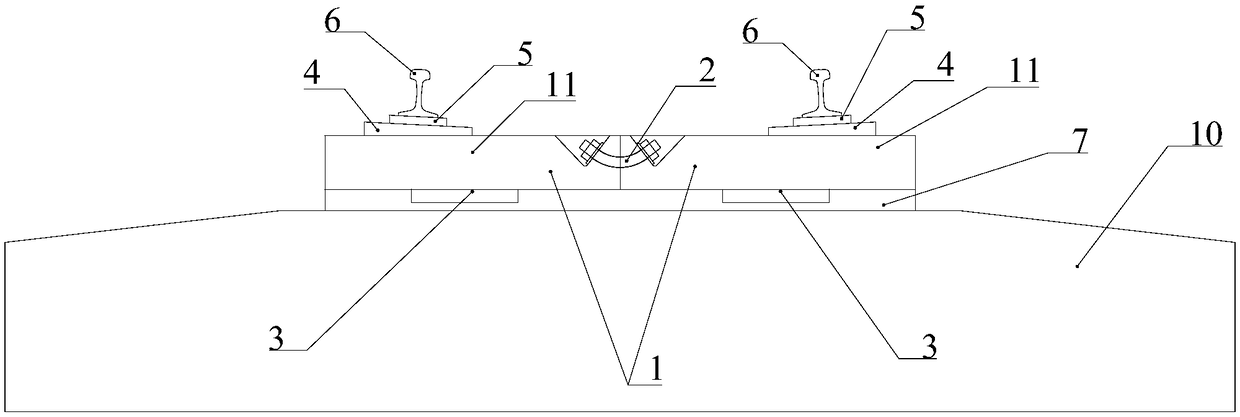

[0036] Such as Figure 1-Figure 3 As shown, a prefabricated ballastless track system includes a steel rail 6, a fastener system 5, a rail support 4, a prefabricated track plate 1, a filling layer 7, and a lower foundation. The present invention has good adaptability, and the lower foundation can be a tunnel foundation 8 (such as figure 1 As shown), bridge foundation 9 (as figure 2 As shown) or subgrade foundation 10 (as image 3 Shown).

[0037] Such as Figure 4-Figure 7 As shown, the prefabricated rail plate 1 includes a plurality of unit plates 11, and a connecting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com