Preparation method and device of additive method rapidly-set fully equiaxed crystal aluminum alloy cast ingot

An aluminum alloy ingot, equiaxed crystal technology, applied in the field of metallurgy, can solve the problems of difficulty in preparing segregation-free ingots, unavoidable local segregation, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

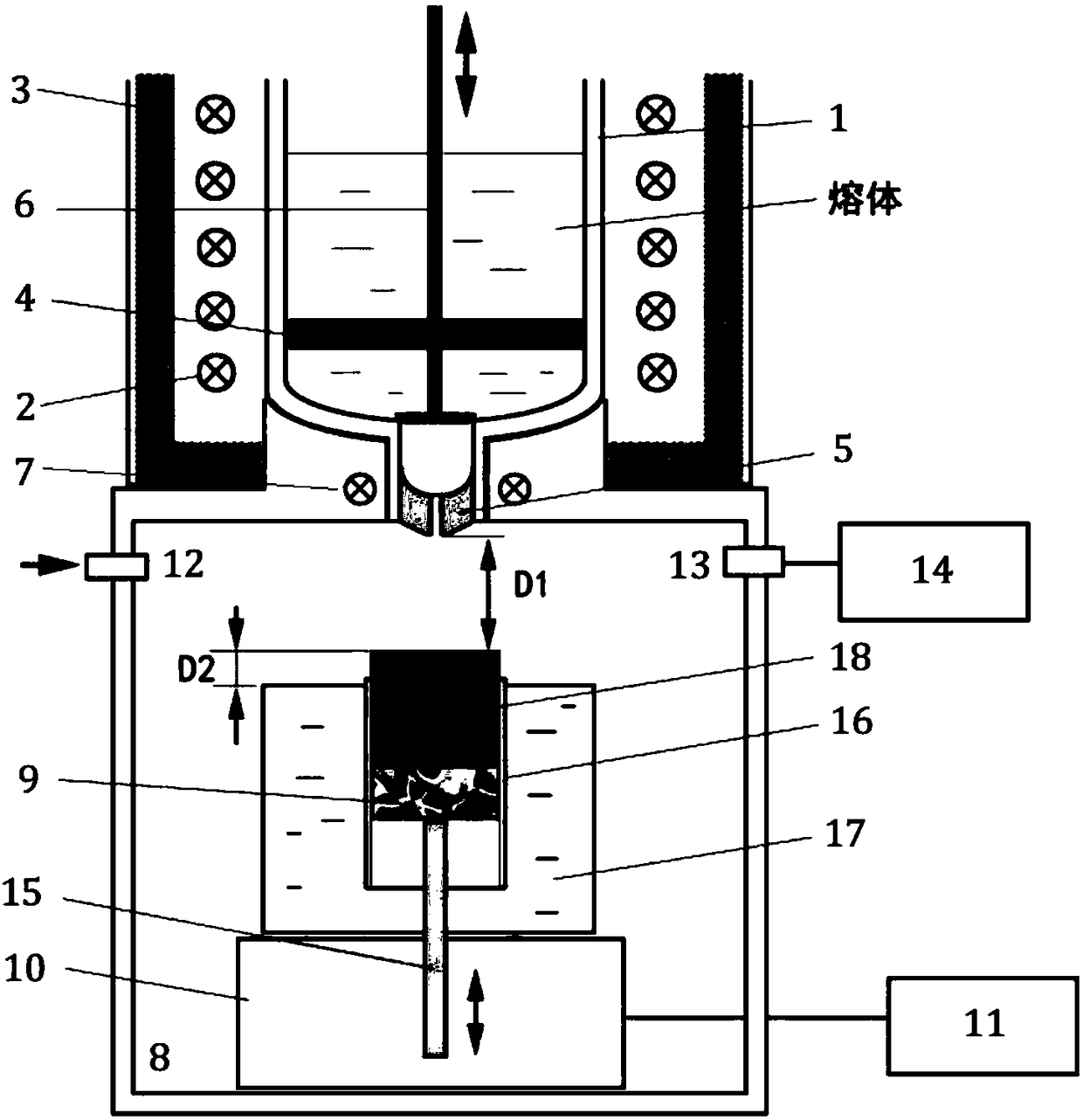

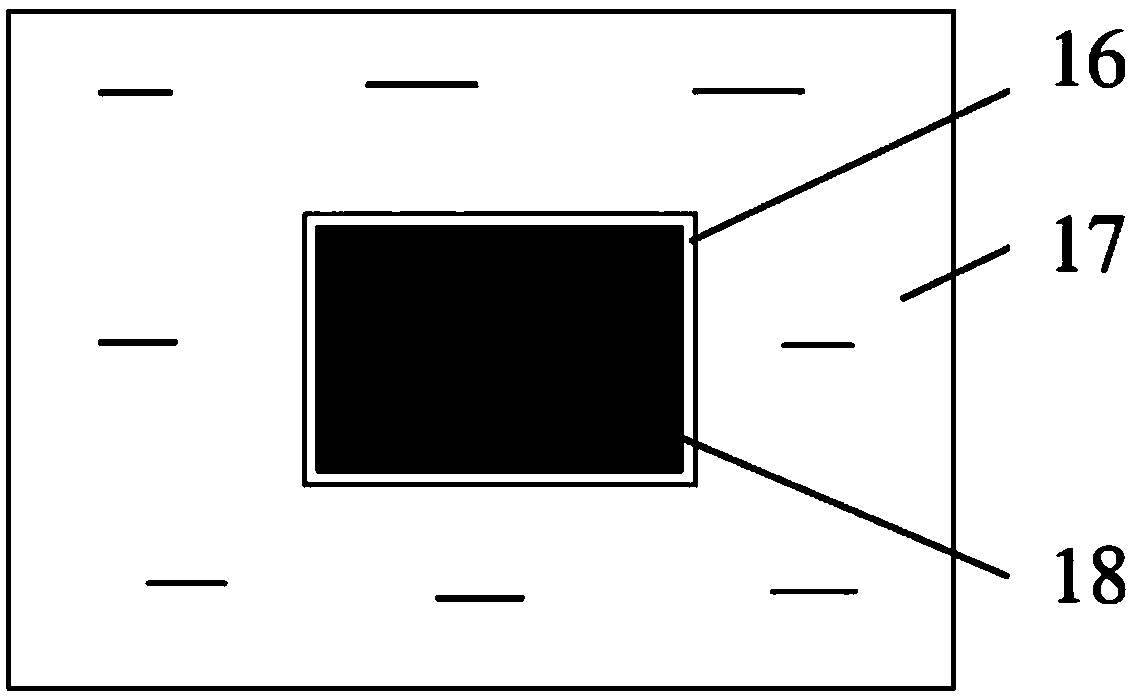

[0026] Such as figure 1 and figure 2 As shown, the device for preparing an ingot of a fully equiaxed crystal aluminum alloy rapidly solidified by the additive method involved in this embodiment includes: a crucible 1, a heater 2, a heat preservation cover 3, a filter device 4, a nozzle 5, a nozzle baffle 6, and a nozzle heating Device 7, vacuum chamber 8, dummy device 9, two-dimensional mobile platform 10, motor 11, air inlet 12, exhaust hole 13, vacuum pump 14, connecting rod 15, sleeve 16, cooling medium 17, moving ingot 18.

[0027] In this embodiment, the above-mentioned device is used, and the molten pure aluminum is poured into the crucible, and the crucible is left there for 1 hour, and the temperature is adjusted to 715°C. Vacuumize the vacuum chamber and fill it with an appropriate amount of argon, so that the air pressure in the vacuum chamber is 0.5 atmospheres, and preheat the nozzle to a temperature of 720°C; set the spray distance to 18cm, and the vertical dist...

Embodiment 2

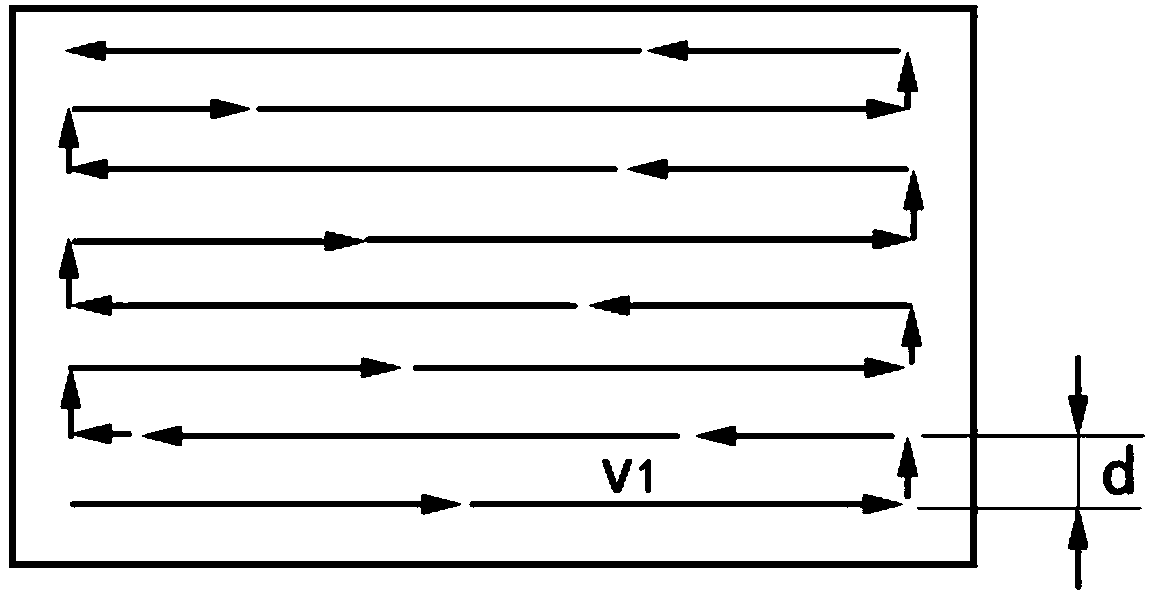

[0030] In this embodiment, the above-mentioned device is used to pour the aluminum-silicon alloy melt with a silicon content of 3% w.t. into the crucible, stay there for 1 hour, and adjust the temperature to 680°C. Vacuumize the vacuum chamber and fill it with an appropriate amount of argon, so that the air pressure in the vacuum chamber is 0.6 atmospheres, and preheat the nozzle to a temperature of 700°C; set the spraying distance to 15cm, and move the contact surface and cooling surface of the ingot The vertical distance is 2.5cm, the moving speed of the two-dimensional mobile platform is 3.5mm / s, and the pass interval is 0.8mm. The moving method is as follows: image 3 . The total displacement of the two-dimensional mobile platform in three directions is set as X=120mm, Y=20mm, Z=80mm respectively. Lift the nozzle baffle, the aluminum liquid in the heat preservation crucible is ejected from the nozzle under the action of the air pressure difference, and at the same time st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com