Device and method for additive manufacturing of gradient material twin-wire twin-tungsten argon arc

A technology of additive manufacturing and argon tungsten arc, which is applied in the field of additive manufacturing devices and devices for additive manufacturing of double-wire double tungsten argon arc of gradient materials, and can solve the inconsistency between the composition distribution of gradient material forming parts and the design goal , reduce the solidification speed of the molten pool, and the performance cannot be guaranteed, etc., to achieve the effect of improving the deposition efficiency, increasing the temperature of the molten pool, and avoiding unstable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

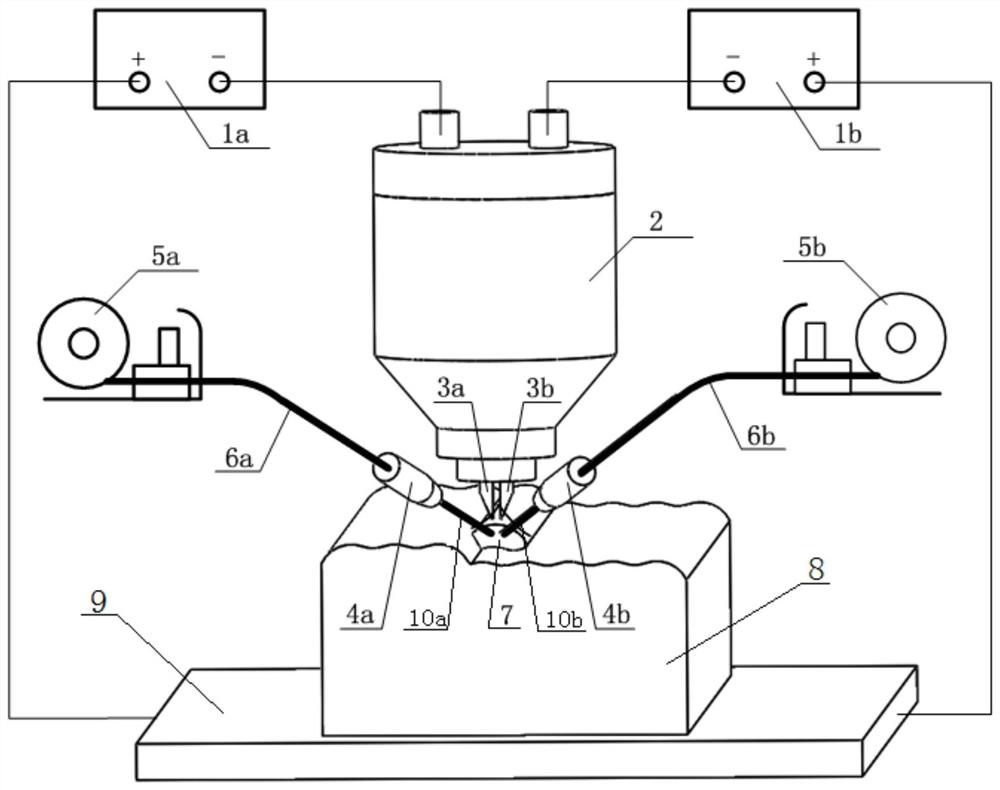

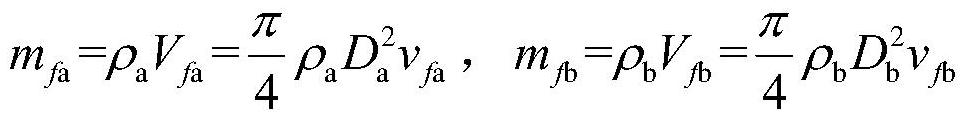

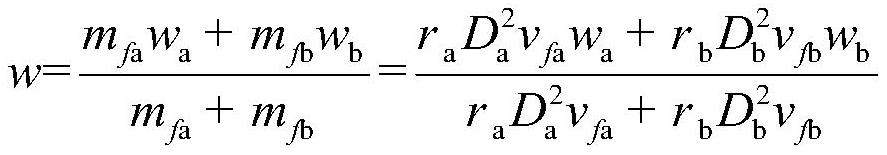

[0033] Specific implementation mode one: see figure 1 This embodiment will be described. A twin-wire double argon tungsten arc additive manufacturing device described in this embodiment includes argon tungsten arc additive manufacturing power supply 1a, argon tungsten arc additive manufacturing power supply 2 1b, double argon tungsten arc additive manufacturing power supply Manufacturing gun 2, partial tungsten pole 1 3a, partial tungsten pole 2 3b, wire guide 1 4a, wire guide 2 4b, wire feeder 1 5a, wire feeder 2 5b, wire feed hose 1 6a and wire feed soft Tube 2 6b;

[0034]The first tungsten electrode 3a and the second tungsten electrode 3b which are insulated from each other are installed under the double tungsten argon arc additive manufacturing gun 2, and the first tungsten electrode 3a and the second tungsten electrode 3b are arranged opposite to each other and connected to each other through cables. The argon tungsten arc additive manufacturing power supply 1a is conn...

specific Embodiment approach 2

[0065] Specific implementation mode two: see figure 1 This embodiment will be described. The device for double-wire double argon tungsten arc additive manufacturing is fixedly installed on a three-degree-of-freedom machine tool. The argon tungsten arc additive manufacturing power supply 1a and the argon tungsten arc additive manufacturing power supply 2 1b both use Ryzen WS- 400 welding machine, DC positive connection; double tungsten argon arc additive manufacturing gun 2 is equipped with partial tungsten electrode 1 3a and partial tungsten electrode 2 3b, the tip angle of partial tungsten electrode 1 3a and partial tungsten electrode 2 3b is 30°, and the tip Place them close to parallel in a "V" shape, and the distance between tungsten electrodes is 1.5mm.

[0066] The double tungsten argon arc additive manufacturing gun 2 is vertically arranged above the molten pool 7, the generated coupling arc is located between the molten pool 7 and the two tungsten electrodes, and the ...

specific Embodiment approach 3

[0082] Specific implementation mode three: see figure 1 This embodiment will be described. The device for double-wire double argon tungsten arc additive manufacturing is fixedly installed on a three-degree-of-freedom machine tool. The argon tungsten arc additive manufacturing power supply 1a and the argon tungsten arc additive manufacturing power supply 2 1b both use Ryzen WS- 400 welding machine; double tungsten argon arc additive manufacturing gun 2 is equipped with partial tungsten electrode 1 3a and partial tungsten electrode 2 3b, the tip angle of partial tungsten electrode 1 3a and partial tungsten electrode 2 3b is 60°, and the tips are placed close to parallel, It is in the shape of "V", and the distance between partial tungsten poles is 2mm.

[0083] The double tungsten argon arc additive manufacturing gun 2 is vertically arranged above the molten pool 7, the generated coupling arc is located between the molten pool 7 and the two tungsten electrodes, and the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com