3D printer forming platform adjusting device and lower projection light curing 3D printer

A 3D printer and adjustment device technology, applied in processing platforms/substrates, 3D object support structures, additive manufacturing, etc., can solve problems such as irreducible errors, printing failures, processing errors, etc., to ensure high consistency and reduce height Error size, effect of improving surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manners of the present invention will be described in more detail below in conjunction with the accompanying drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

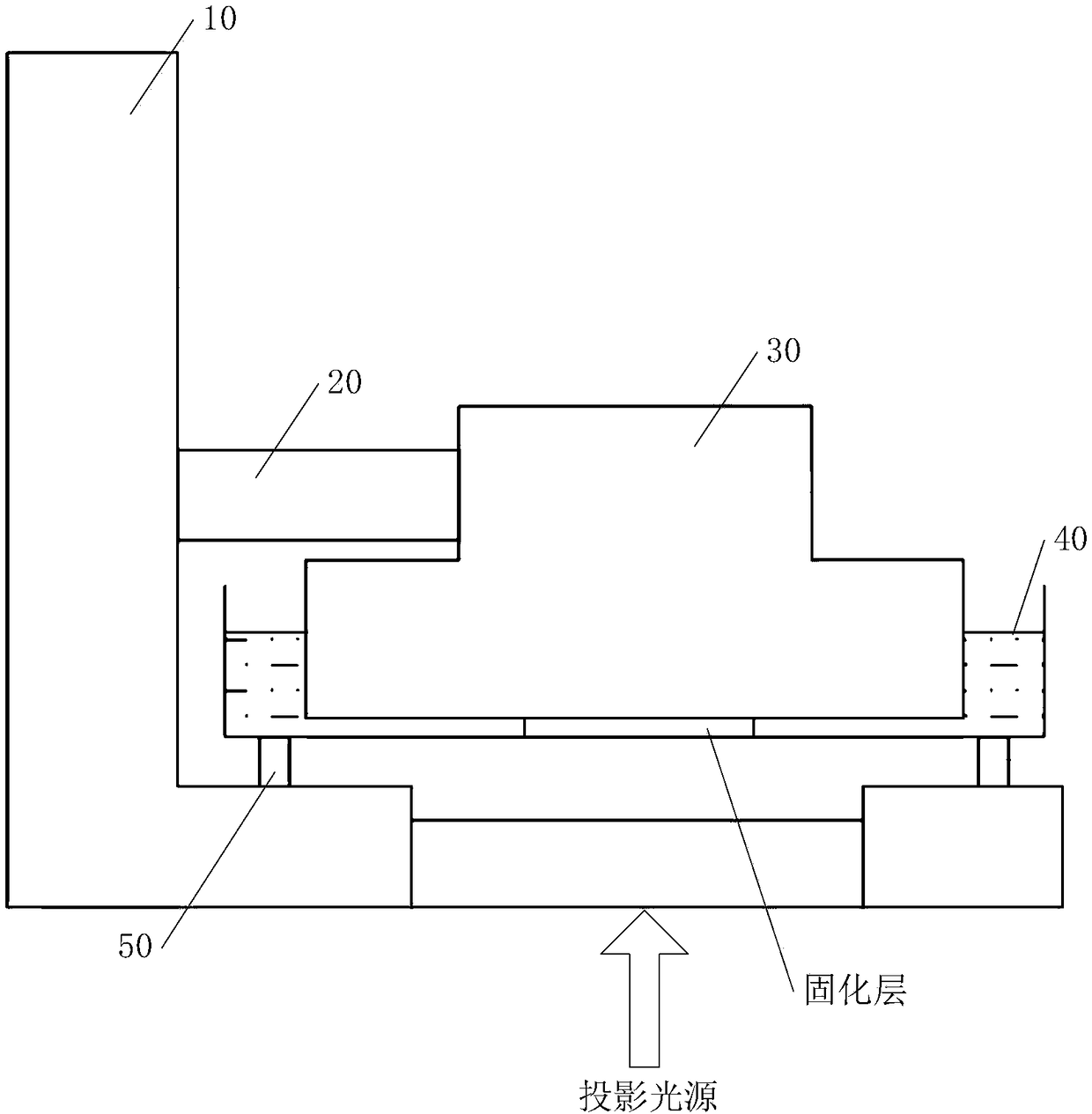

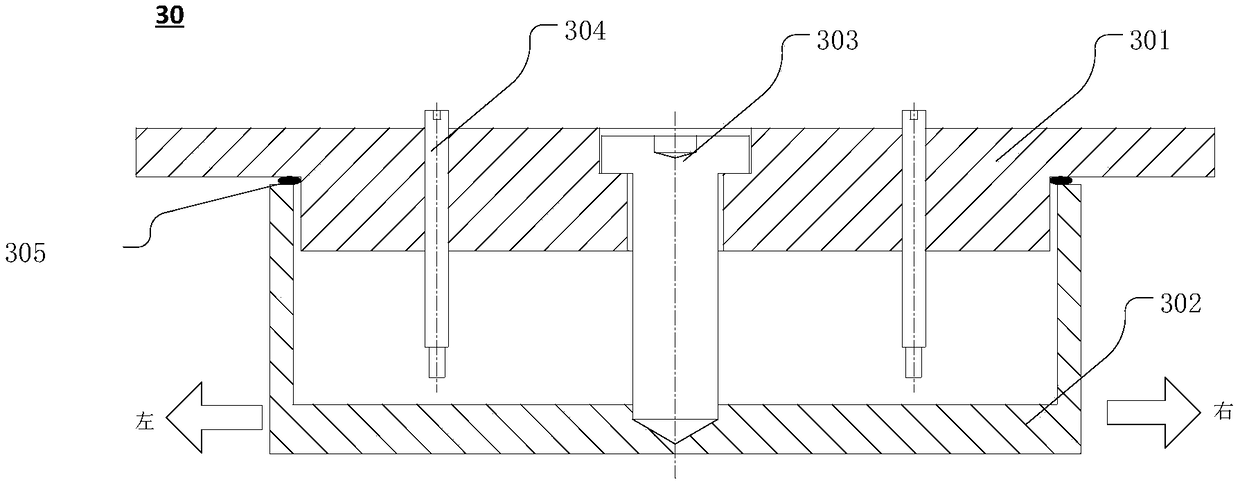

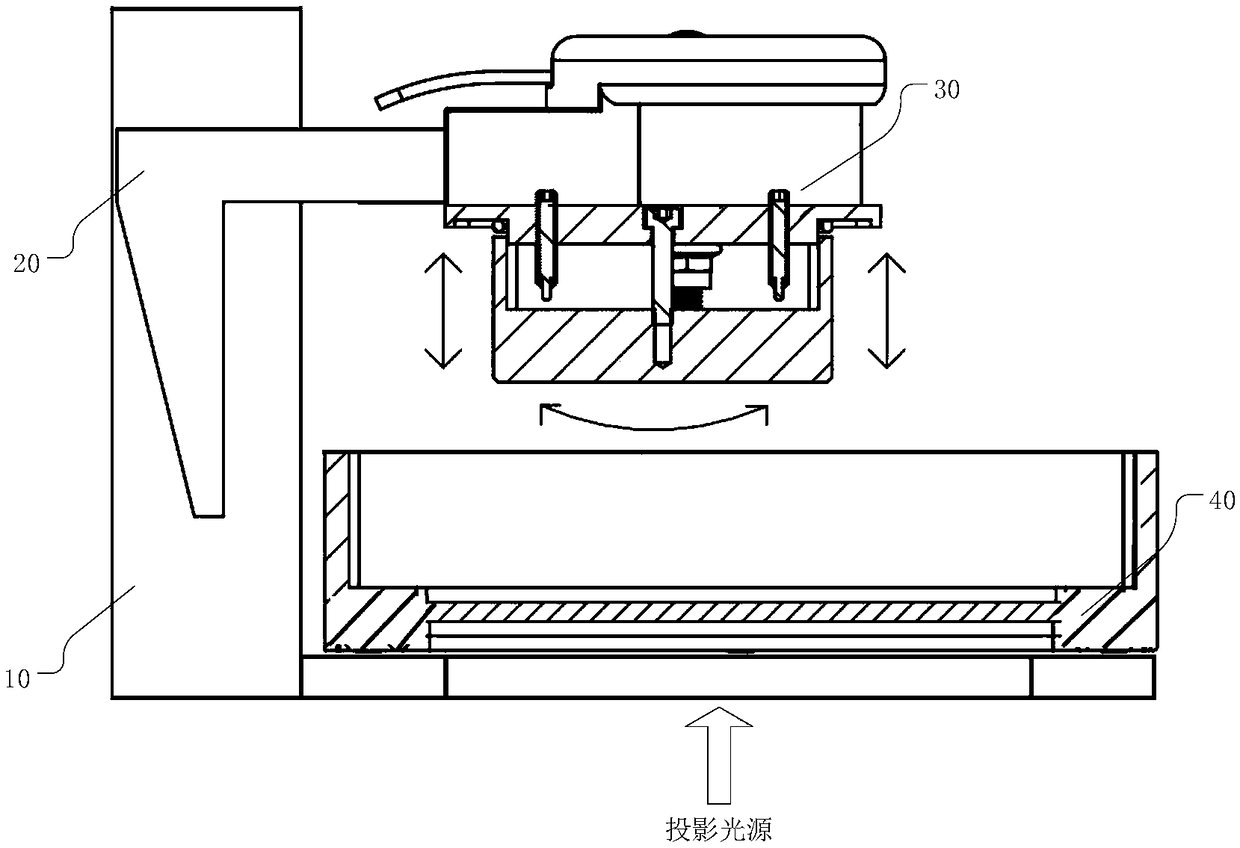

[0054] Such as figure 2 Shown is a schematic structural view of an embodiment of the forming platform adjusting device of the present invention. The forming platform adjustment device is specifically applied to a down-projection light-curing 3D printer, and the forming platform adjustment device includes: a forming seat tray 301 , a forming seat 302 , a tension member 303 and a tightening member 304 . The upper surface of the forming seat tray 301 is crimped on the cantilever 20 of the forming platform, and is provided with at least three first threaded through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com