Printed circuit board laminating cushion and preparation method thereof

A printed circuit board and buffer pad technology is applied in the field of a printed circuit board lamination buffer pad and its preparation, which can solve the problems of prolonging the printing circuit board preparation process time, decreasing product output, reducing production efficiency, etc., and saving heating time. and lamination process time, increase productivity, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the printed circuit board lamination buffer pad described in the present embodiment comprises the following steps:

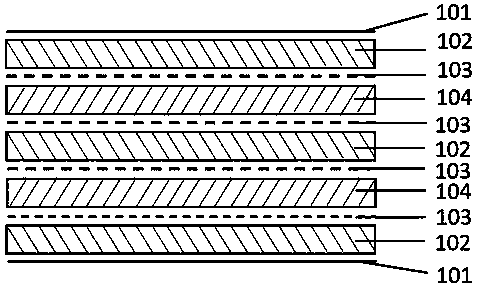

[0054] a. Weave aramid fiber 1414 and graphene fiber into tulle respectively; then the two outer layers are aramid fiber 1414 tulle, and the two outer layers are graphene fiber tulle and aramid fiber from bottom to top. 1414 tulle, graphene fiber tulle, and aramid 1414 base cloth between two adjacent layers of tulle are laminated; the above laminate is placed in a needle punching machine and needled into a felt pad. The felt pad includes four layers of aramid fiber 1414 base cloth, three layers of aramid fiber 1414 tulle and two layers of graphene fiber tulle.

[0055] b. Arrange PTFE glass fiber glue on the upper and lower surfaces of the felt pad, and make a high thermal conductivity cushion under the conditions of temperature of 150°C, vehicle speed of 20m / min, and pressure of 6Mpa.

[0056] The longitudinal section view of t...

Embodiment 2

[0058] The preparation method of the printed circuit board lamination buffer pad described in the present embodiment comprises the following steps:

[0059] a. Weave aramid fiber 1414 and silicon nitride fiber into tulle respectively; then the two outer layers are aramid fiber 1414 tulle, and the two outer layers are silicon nitride fiber tulle and aramid fiber tulle from bottom to top. Lamination of 1414 rayon fiber tulle, silicon nitride fiber tulle, and aramid 1414 base cloth between two adjacent layers of tulle; the above lamination is placed in a needle punching machine to form a felt pad. The felt consists of four layers of aramid 1414 base fabric, three layers of aramid fiber 1414 tulle and two layers of silicon nitride fiber tulle.

[0060] b. Arrange PTFE glass fiber glue on the upper and lower surfaces of the felt pad, and make a high thermal conductivity cushion under the conditions of temperature of 150°C, vehicle speed of 20m / min, and pressure of 6Mpa.

Embodiment 3

[0062] The preparation method of the printed circuit board lamination buffer pad described in the present embodiment comprises the following steps:

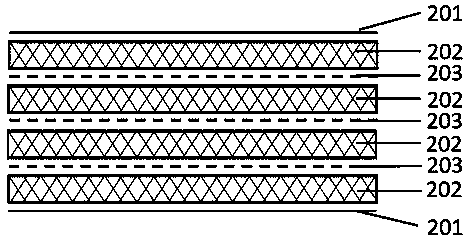

[0063] a. Fully mix aramid fiber 1414 and silicon nitride fiber in a weight ratio of 3:1, and weave a mixed tulle; The middle is the lamination method of aramid fiber 1414 base cloth; the above lamination is placed in a needle punching machine and needled into a felt pad. The felt consists of three layers of aramid 1414 base fabric, four layers of aramid fiber 1414 and silicon nitride fiber mixed tulle.

[0064] b. Arrange PTFE glass fiber glue on the upper and lower surfaces of the felt pad, and make a high thermal conductivity cushion under the conditions of temperature of 160°C, vehicle speed of 20m / min, and pressure of 5Mpa.

[0065] The longitudinal sectional view of the high thermal conductivity buffer pad is as follows: figure 2 As shown, 201 is PTFE fiberglass viscose cloth, 202 is mixed tulle, and 203 is aramid 1414 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com