Cotton fiber membrane, application of cotton fiber membrane and luminescent microbial culture membrane

A microbial culture and cotton fiber technology, applied in the field of fiber membranes, can solve problems such as weak adsorption capacity, achieve strong smoothness, reduce surface roughness, and smooth the upper and lower surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

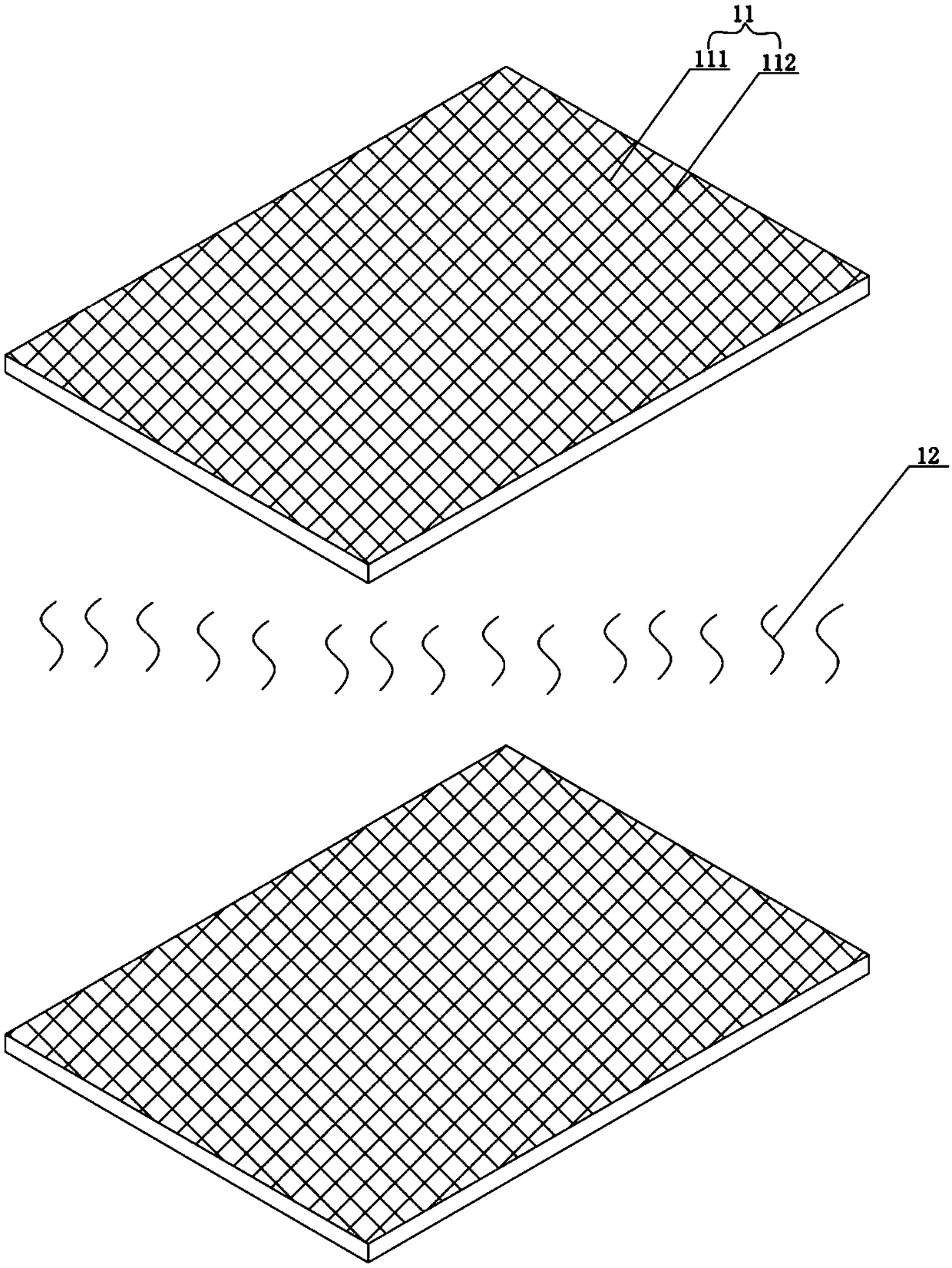

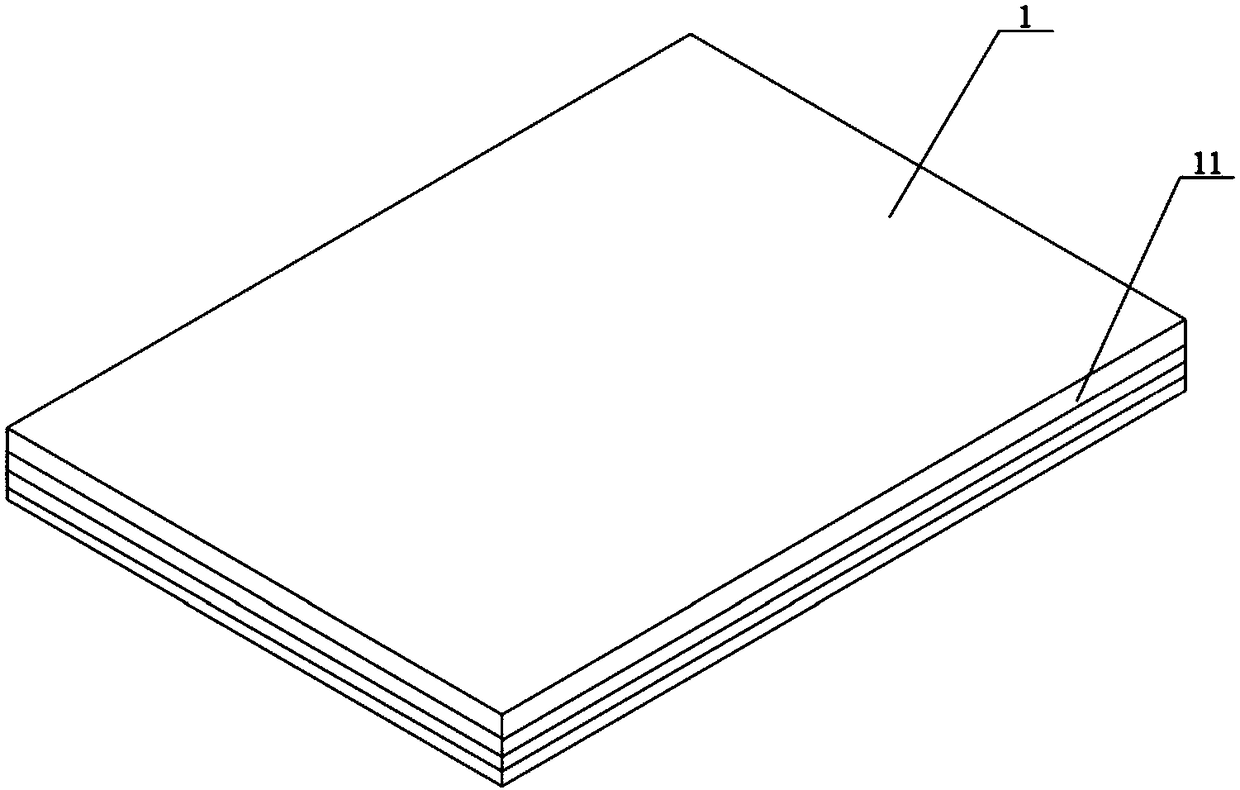

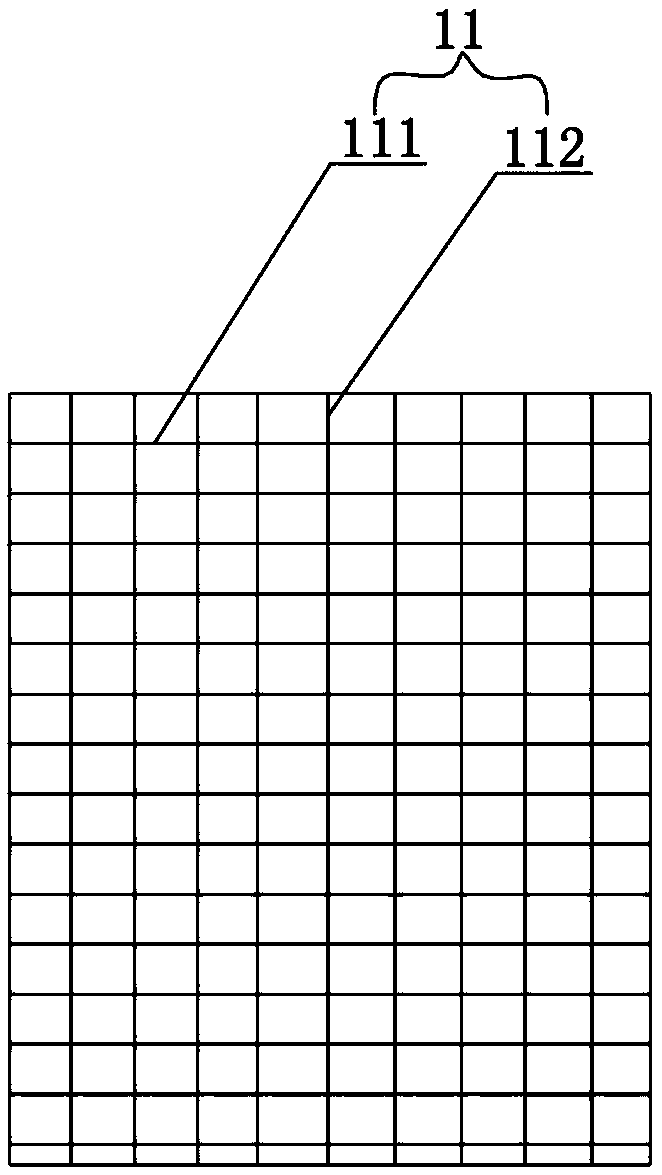

[0047] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a cotton fiber film 1, the cotton fiber film 1 is formed by successively stacking and pressing two or more cotton fiber layers 11, and the adjacent two layers of cotton fiber layers 11 are connected by connecting cotton fibers 12, and the cotton fiber layers Layer 11 comprises the first direction cotton fiber 111 and the second direction cotton fiber 112 that are interlaced with each other, and the density of the cotton fiber layer 11 that is positioned at the top layer and the bottom layer in the cotton fiber film 1 is the cotton fiber that is positioned at the middle layer in the cotton fiber film 1. 1.5-2.5 times of the density of layer 11, the aperture of the cotton fiber layer 11 positioned at the top and bottom layer in the cotton fiber membrane 1 is 1 / 2 to 1 / 3 of the aperture of the cotton fiber layer 11 positioned at the middle layer in the cotton fiber membrane 1 .

[0048] See image 3 , Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com