Alkali-free liquid accelerator and preparation method thereof

A technology of accelerator and liquid, which is applied in the field of non-alkali liquid accelerator and its preparation, which can solve the problems of poor stability of non-alkali liquid accelerator, increase solubility and ion group stability, and shorten setting time , the effect of increased crystallization resistance

Active Publication Date: 2018-11-13

武汉优城科技有限公司

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to solve the problem of poor stability of common alkali-free liquid accelerators and achieve good concrete quick-setting effects and early strength requirements, the invention provides an alkali-free liquid accelerator and its preparation method, specifically through the following techniques accomplish

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

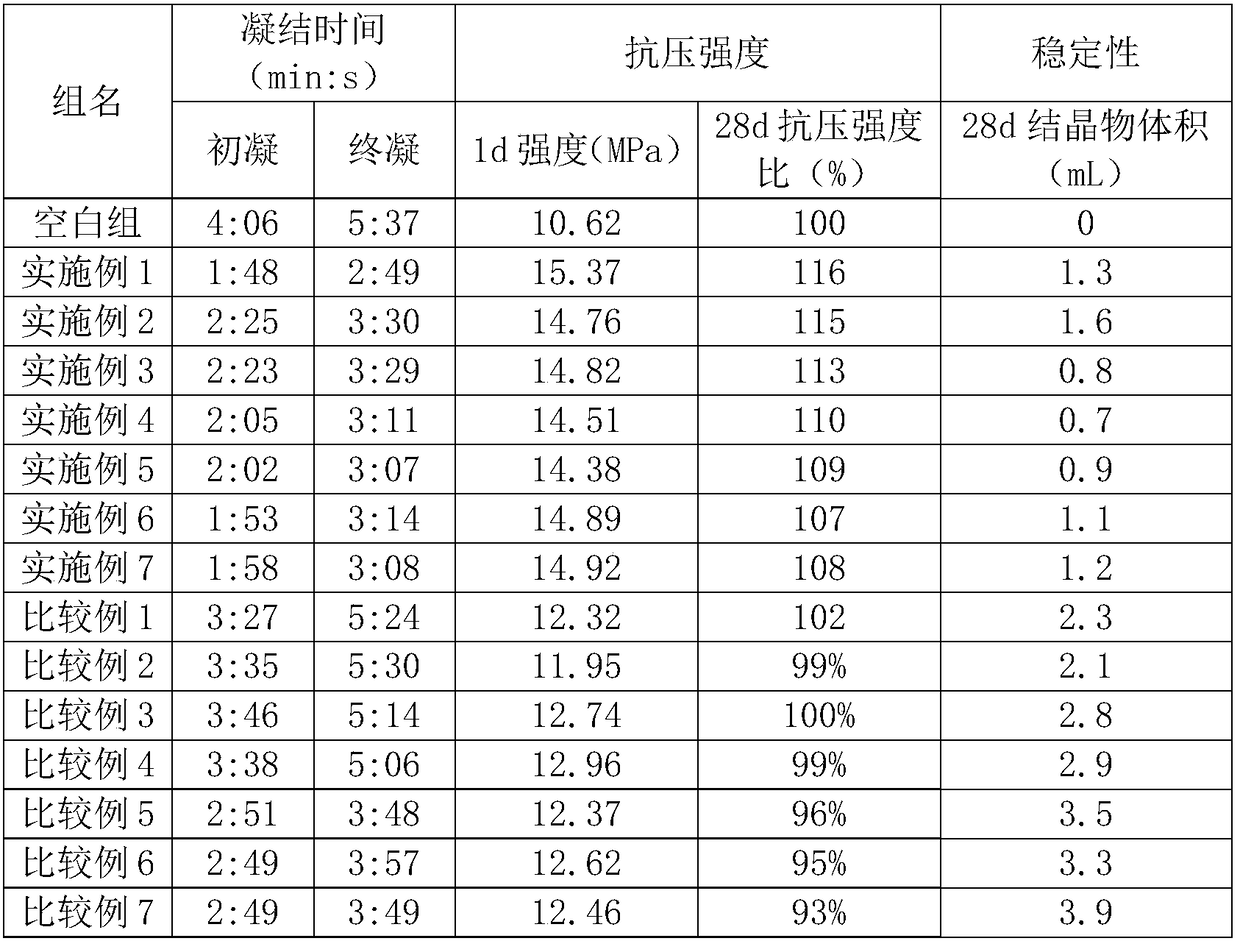

Embodiment 1~7 and comparative example 1~7

[0037] Examples 1-7 and Comparative Examples 1-7 provide a non-alkali liquid quick-setting agent, the weight percentage of its components, and the mesh size of the selected sepiolite ore powder are shown in Table 1.

[0038] The weight percent of the component of a kind of non-alkali liquid quick-setting agent of table 1 embodiment 1~7 and comparative example 1~7 and sepiolite ore powder mesh number

[0039]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an alkali-free liquid accelerator and a preparation method thereof. The alkali-free liquid accelerator is prepared from, by weight, 45%-55% of aluminum sulfate, 1%-5% of aluminum hydroxide, 1%-5% of phosphoric acid, 1%-3% of diethanol amine, 1%-3% of glycollic acid, 0.5%-2% of sepiolite mineral powder, 0.5%-2% of bisphenol condensation compound and the balance deionized water. The preparation method of the alkali-free liquid accelerator comprises the steps that the aluminum hydroxide and the aluminum sulfate are successively dissolved, the bisphenol condensation compound and the sepiolite mineral powder are added to complete viscosity improvement, and finally residual components are added to complete organic compounding. The bisphenol condensation compound and the sepiolite mineral powder are added into the alkali-free liquid accelerator, its tiny granules and thin and short fibers are evenly dispersed in the solution to form a crosslinking net-like structure, the crystallizing resistance of sulfate radicals and aluminum ions is greatly improved, water molecules and aluminum sulfate difficultly produce crystallization and sedimentation and good solubilizingand stabilizing effects are achieved. The concrete setting time is effectively shortened by the glycollic acid and the diethanol amine, and the early strength of concrete is improved.

Description

technical field [0001] The invention belongs to the technical field of concrete preparation, in particular to an alkali-free liquid quick-setting agent and a preparation method thereof. Background technique [0002] Alkali-free liquid accelerator is the latest generation product of accelerator development. Compared with traditional powder accelerator and alkali accelerator, alkali-free liquid accelerator almost completely eliminates the alkaline substances in it, avoiding It prevents the damage of concrete by alkali aggregate reaction, and has a high later strength retention rate; on the other hand, it contains almost no chloride ions, which eliminates the possibility of steel corrosion and improves the durability of reinforced concrete structures. [0003] However, there is also a technical bottleneck in the development of non-alkali liquid accelerators. Most non-alkali liquid accelerators are mainly composed of aluminum sulfate or polyaluminum sulfate systems. At room tem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/12C04B103/12

CPCC04B40/0039C04B2103/12C04B22/148C04B22/06C04B22/165C04B24/122C04B24/02C04B14/042C04B22/002

Inventor 陈健董耀武代柱端周晓阳

Owner 武汉优城科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com