Method for preparing furandimethanol diether by catalytic furandimethanol etherification

A technology of furandimethanol diether and furandimethanol, which is applied in the field of preparation of furandimethanol diether, can solve the problems of difficult product separation, many side reactions, and low yield of diether products, and achieve improved diffusion limit, reduction of The effect of by-product formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for furandimethanol dimethyl ether, comprising the steps of:

[0039] S1. Get 15g of hydrothermally synthesized microporous ZSM-5 molecular sieve (for example: produced by Tianjin Nanhua Catalyst Co., Ltd.) (http: / / www.nkcatalyst.com / );

[0040] S2. Add 300ml of 0.5M HCl solution, stir and react at 50°C for 6h, filter, wash with deionized water, and dry to obtain a hierarchical porous silica-alumina molecular sieve (HP-ZSM-5-1);

[0041] S3. Take 5g of HP-ZSM-5-1 and put it into a 10ml fixed-bed reactor;

[0042] S4. The temperature of the fixed-bed reactor is raised to 65°C, and a mixed liquid is introduced. The liquid composition is: 10mol% BHMF, 90mol% methanol, and the liquid flow rate is 1.0h -1 , the product was detected by HPLC, and the yield of furandimethanol dimethyl ether (BMMF) was 99%.

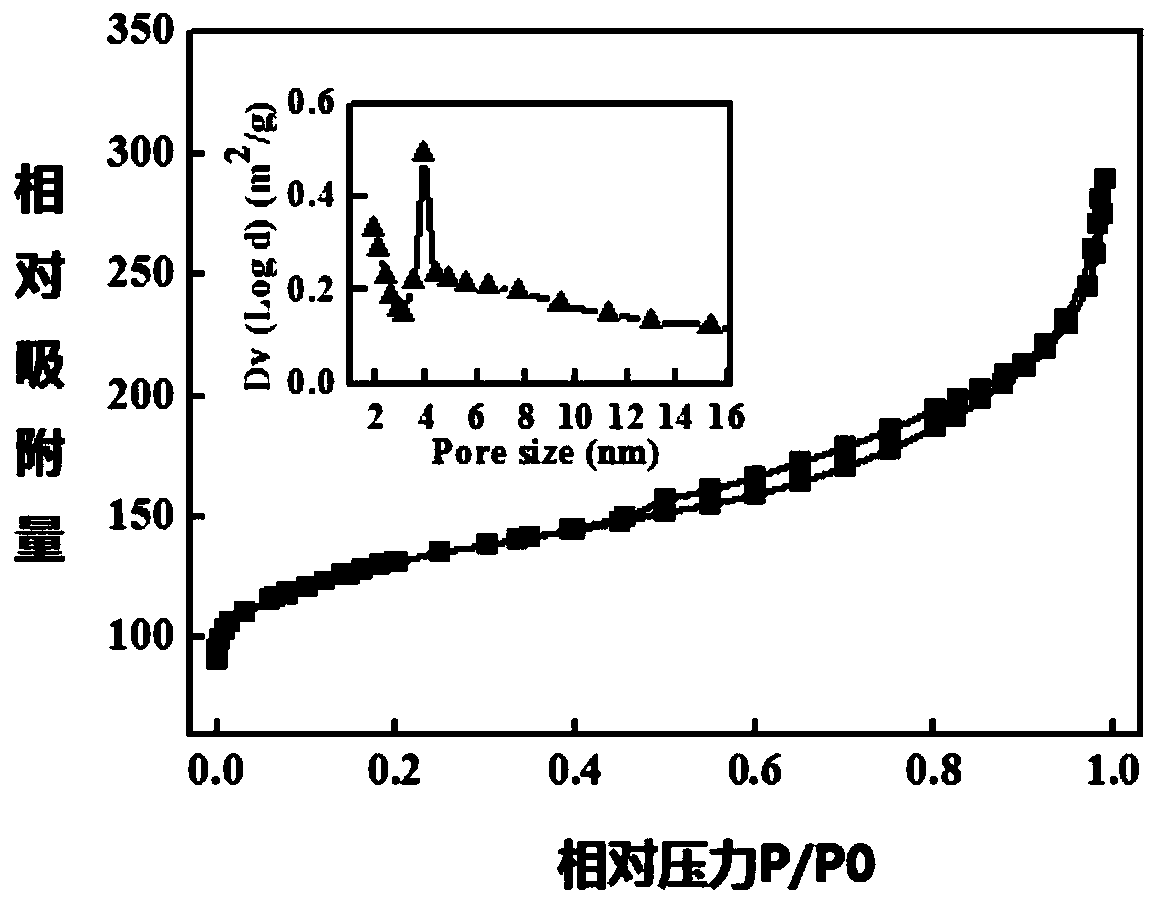

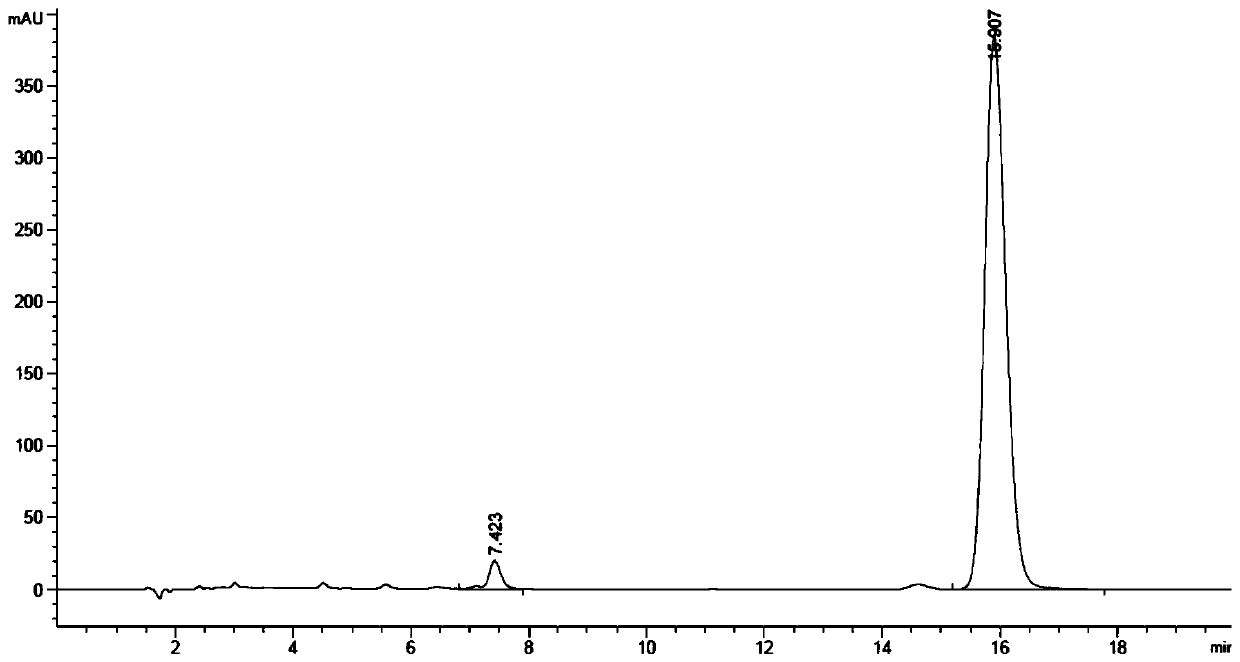

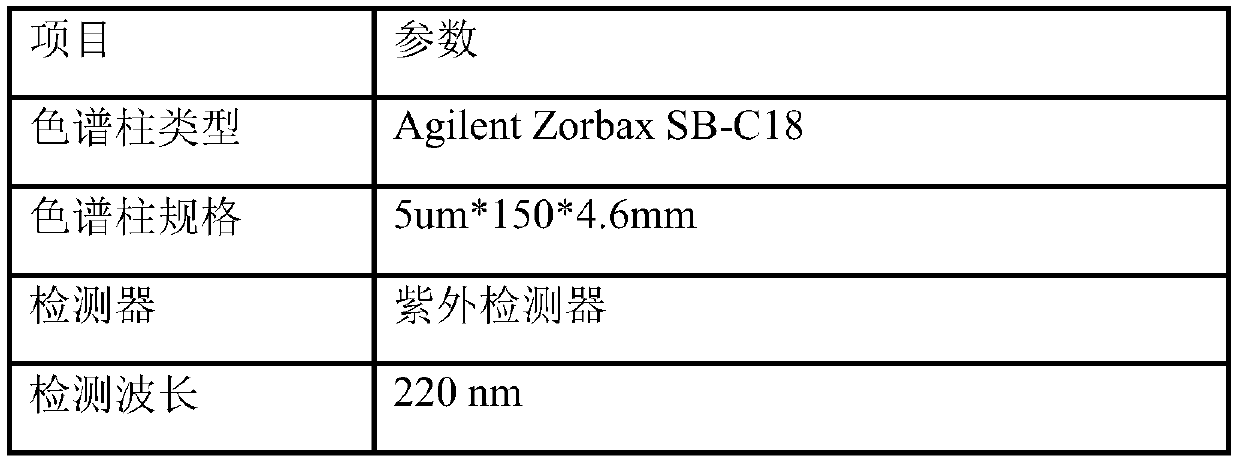

[0043] figure 1 The BET test results of the HP-ZSM-5-1 sample are given, figure 2 The HPLC analysis result spectrum is given.

Embodiment 2

[0045] A preparation method for furandimethanol dimethyl ether, comprising the steps of:

[0046] S1, get 20g of hydrothermally synthesized microporous ZSM-5 molecular sieves;

[0047] S2. Add 300ml of 1M NaOH solution, stir and react at 60°C for 8h, filter, wash, and dry to obtain a hierarchical porous silica-alumina molecular sieve (HP-ZSM-5-2).

[0048] S3, get 5g HP-ZSM-5-2 and pack in 10ml fixed-bed reactor,

[0049] S4. The temperature of the fixed-bed reactor is raised to 50°C, and a mixed liquid is introduced. The liquid composition is: 10% BHMF, 90% ethanol, and the liquid flow rate is 0.5h -1 , the product was detected by HPLC, and the yield of furandimethanol diethyl ether (BEMF) was 97%.

Embodiment 3

[0051] A preparation method for furandimethanol dimethyl ether, comprising the steps of:

[0052] S1, get 10g of hydrothermally synthesized microporous Beta molecular sieve (for example: produced by international catalyst company zeolystinternational), http: / / www.zeolyst.com;

[0053] S2. Add 300ml of 0.5M HCl solution, stir and react at 60°C for 6h, filter, wash, and dry to obtain a hierarchical porous silica-alumina molecular sieve (HP-Beta-1).

[0054] S3, get 5g HP-Beta-1 and pack in 10ml fixed-bed reactor,

[0055] S4. The temperature of the fixed-bed reactor is raised to 60°C, and a mixed liquid is introduced. The liquid composition is: 10% BHMF, 90% methanol, and the liquid flow rate is 1h -1 , the product was detected by HPLC, and the yield of furandimethanol dimethyl ether (BMMF) was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com