Soft measurement method for size of austenite grains in heating process of steel billet

A technology for heating austenite grains and steel slabs, applied in heat treatment process control, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of not being able to know the dynamic changes of austenite grains, affecting product performance, and energy waste, etc., to achieve Accurate control, improve heating quality, and reduce energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

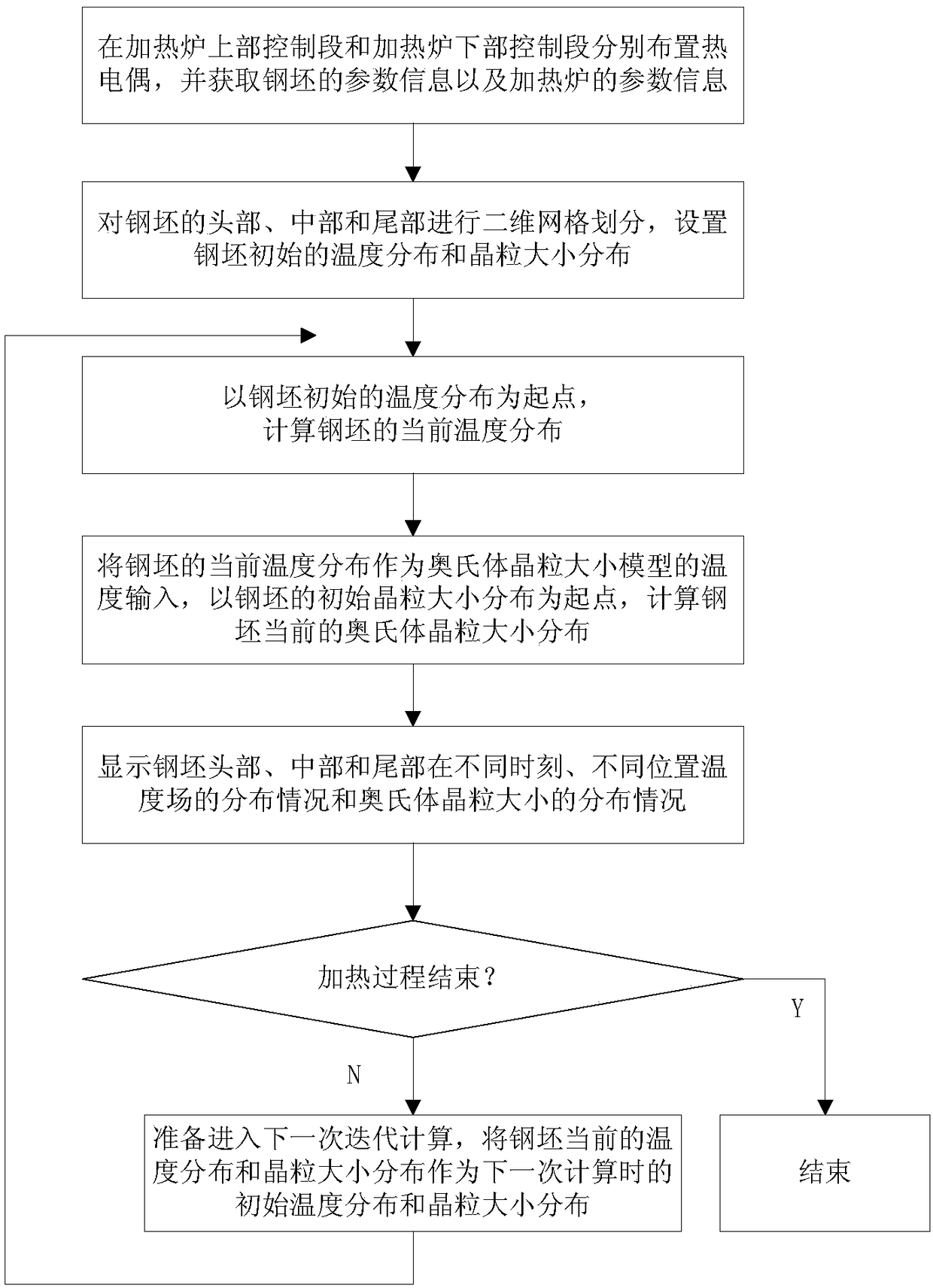

Method used

Image

Examples

Embodiment 1

[0067] Example 1 (slab and billet)

[0068] The low-carbon steel slab enters the heating furnace for heating, and after the heating is completed, it is rolled out of the furnace. The chemical composition of the steel slab is:

[0069] element name

C

Si

mn

Nb

Ni

content

0.058

0.43

1.68

0.051

0.17

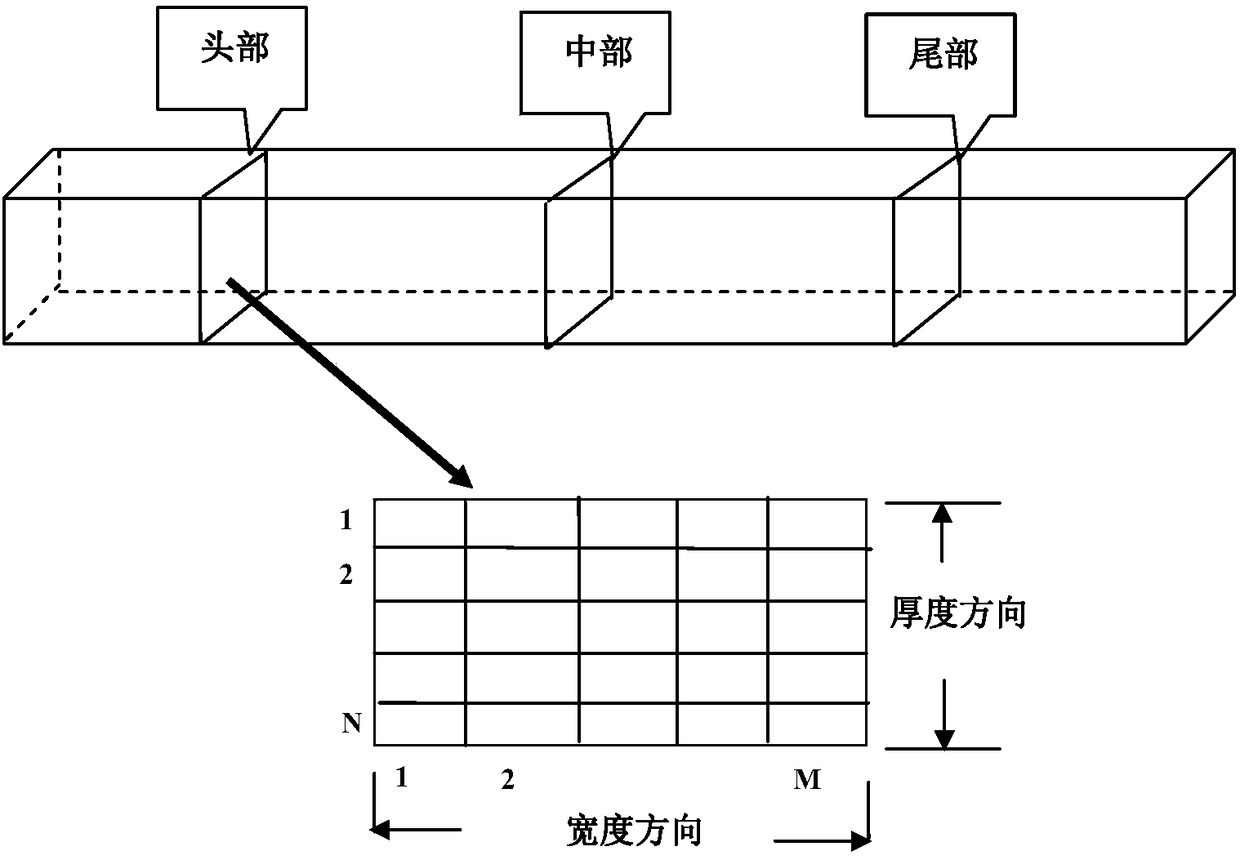

[0070] Firstly, according to step 1 and step 2, the parameter information of the billet is obtained, and the temperature distribution and grain size distribution of the billet are set. The thickness of the billet is 200mm, the width is 300mm, and the length is 10m. For the first calculation, the temperature distribution of the slab is set to the actual measured surface temperature at the time of furnace charging i=1,2,3,4,5; j=1,2,3,4,5; the initial grain size distribution of the billet is set as k=1, 2, 3 represent head, middle and tail respectively.

[0071] The heating process is as follows, the upper part of the heating...

Embodiment 2

[0081] Embodiment 2 (round billet)

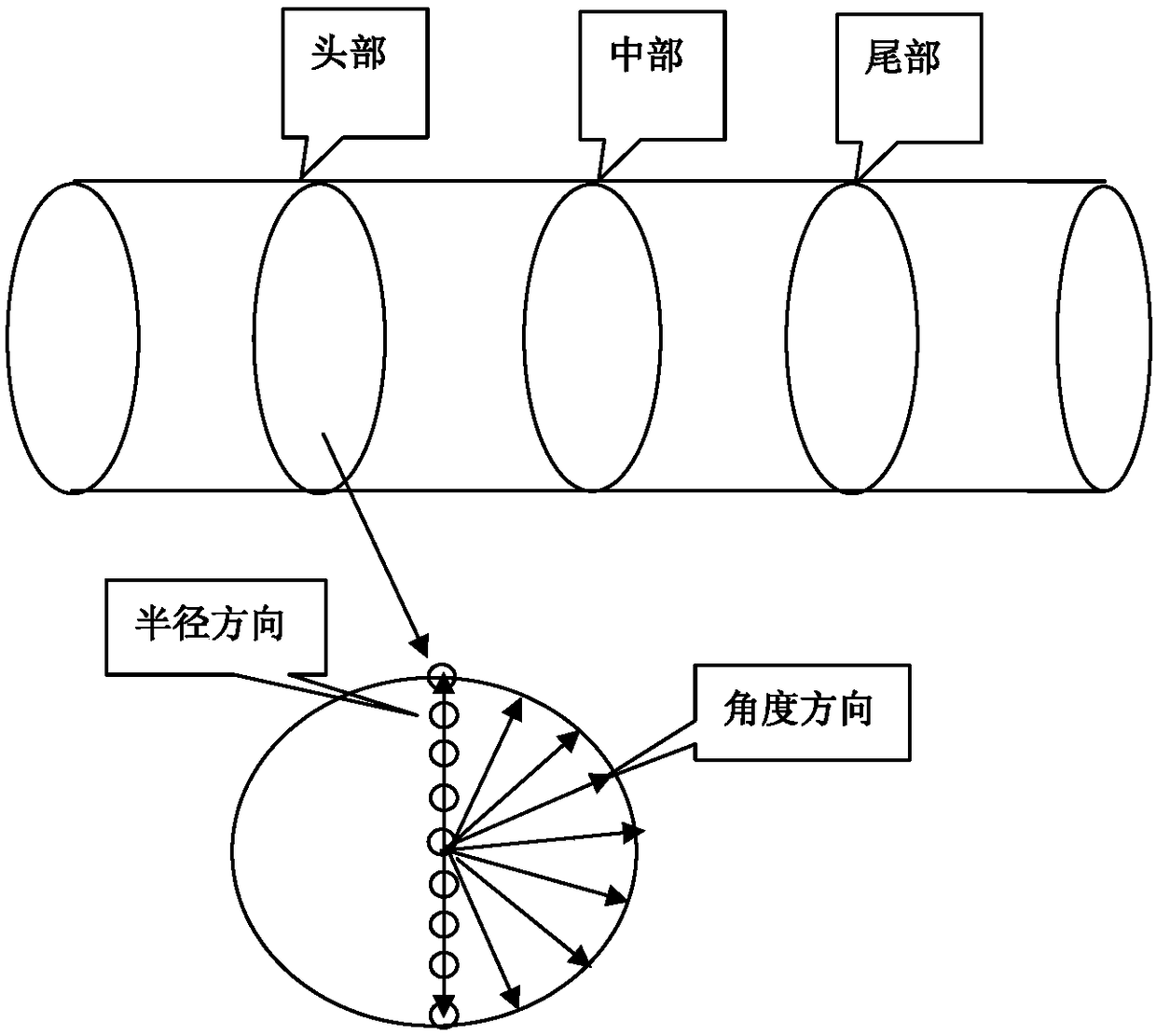

[0082] In this embodiment, the round billet has a diameter of 300 mm, low carbon steel, and the composition is the same as in Embodiment 1. meshing as image 3 , the radial direction is divided into 7, and the angular direction is divided into 9. The initial temperature and grain size of the round billet are the same as in Example 1.

[0083] The heating process is as follows:

[0084]

heat recovery section

Preheating section

Heating section

soaking section

temperature °C

700

1100

1280

1250

time min

30

30

85

35

[0085]In this case, the round billet adopts one-sided heating, and the same method as in Example 1 is used to calculate the heat flux at the top of the round billet. The radiation coefficient of the upper part is 0.9, and the radiation coefficient of the side is linearly decreased from 0.9 to 0.25 from the top to the bottom.

[0086] The calculated temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com