Composite material heald frame based on laminated board structure

A technology of composite materials and composite material layers, applied in the field of composite material heald frames, can solve problems such as large vibration and noise, and cannot meet the working requirements of new modern looms, so as to suppress vibration and noise, improve loom speed and weaving efficiency , to reduce the effect of inertial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

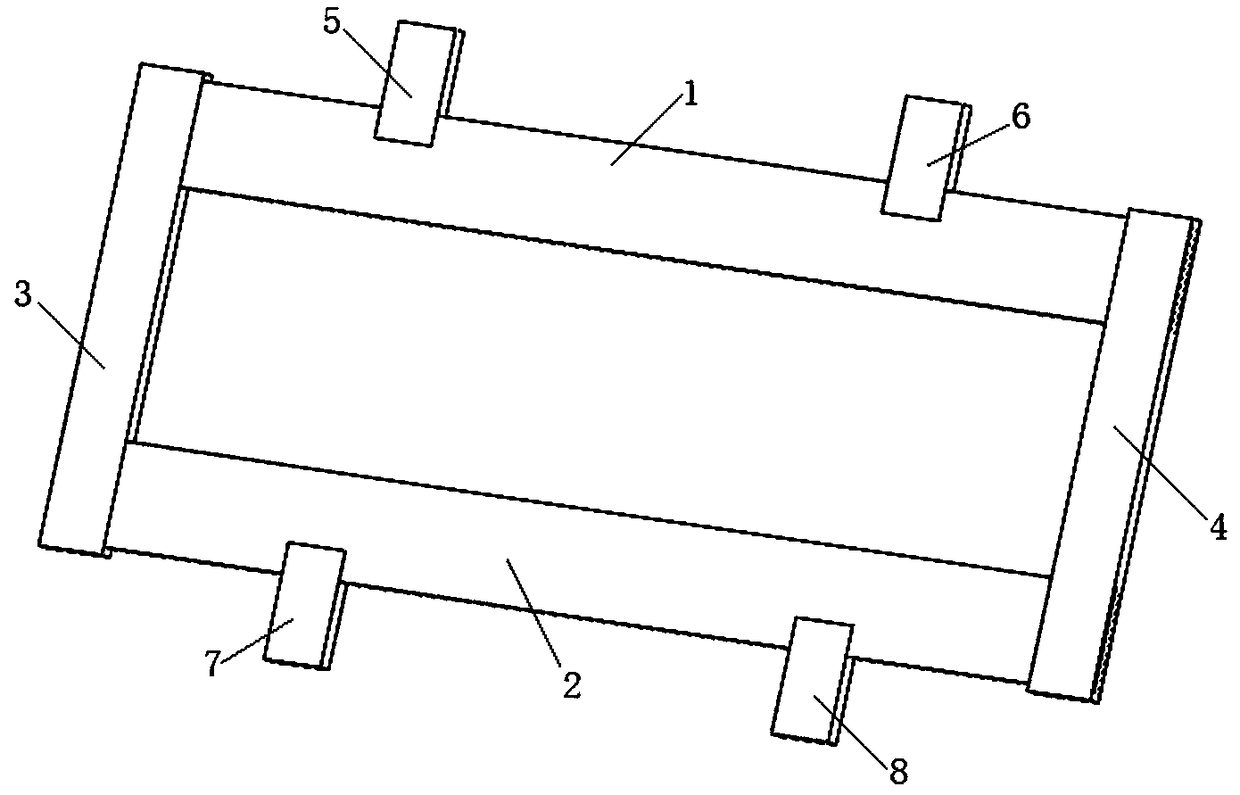

[0017] Such as figure 1 As shown, a composite material heald frame based on a laminated board structure adopts a planar frame structure, including a first beam 1 and a second beam 2, and the two ends of the first beam 1 and the second beam 2 are respectively connected to the first side rail 3 , The second side rail 4 is rigidly connected, the first guide plate 5 and the second guide plate 6 are installed on the first beam 1, the third guide plate 7 and the fourth guide plate 8 are correspondingly installed on the second beam 2, the first beam 1. The second beam 2, the first side rail 3, the second side rail 4, the first guide plate 5, the second guide plate 6, the third guide plate 7, and the fourth guide plate 8 are all pressed by four layers of carbon fiber composite laminates .

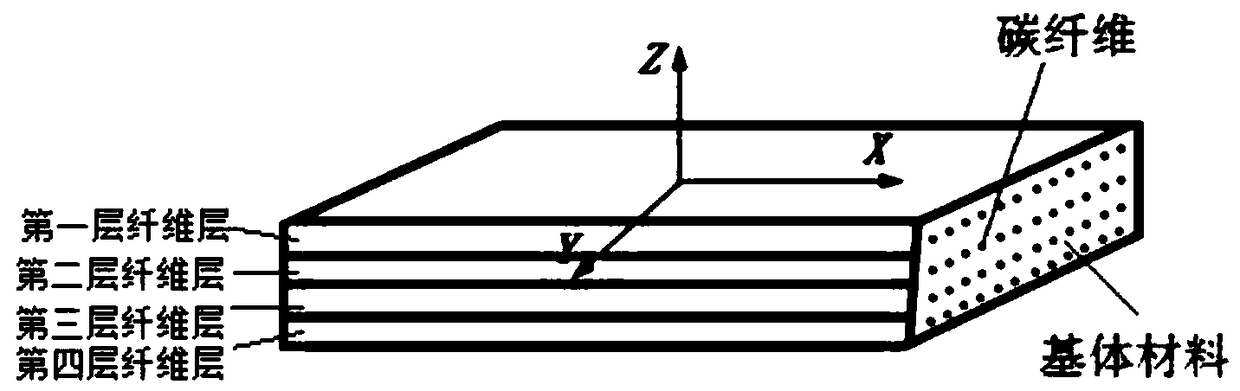

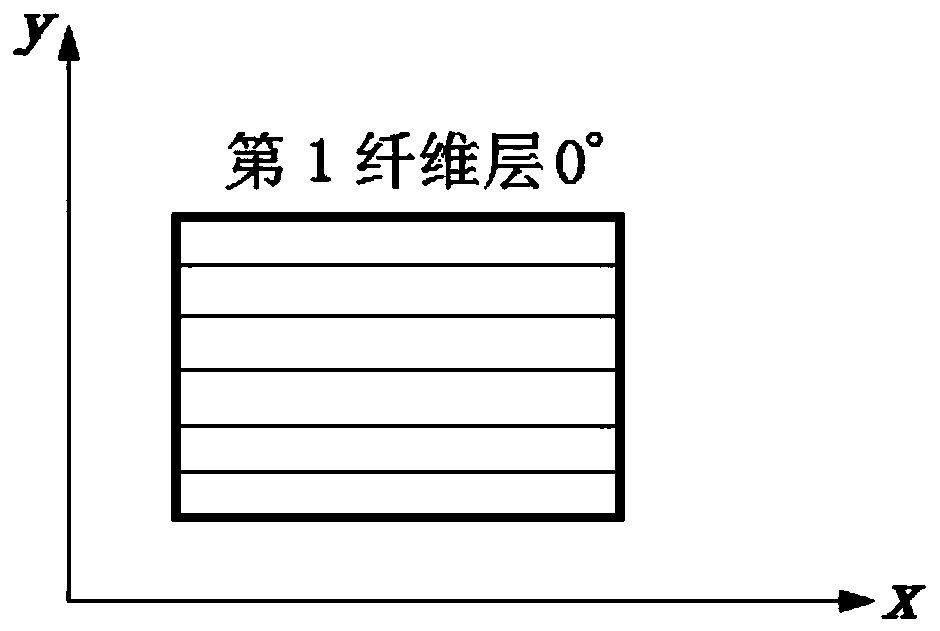

[0018] Such as figure 2 As shown, for the four-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com