Water cushion slope-shifting height adjustable counterweight dam

A technology of water pads and water-facing slopes, applied in water conservancy projects, sea area projects, buildings, etc., can solve problems such as high construction requirements, blockage of diversion channels, failure to achieve expected control effects, etc., and achieve high overall stability and convenience transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

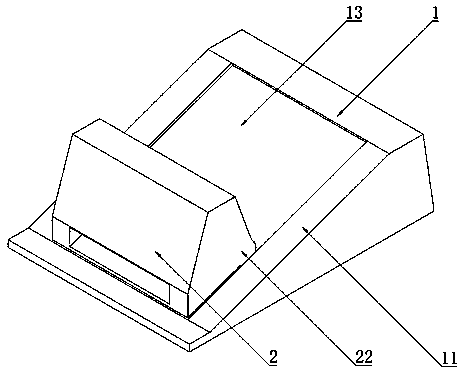

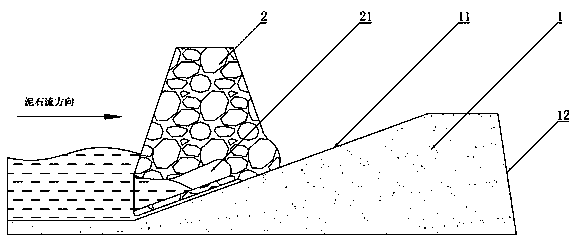

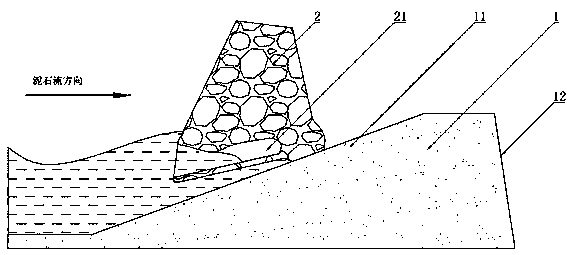

[0043] Such as Figure 1 ~ Figure 4 As shown, a water cushion slope-shifting height-adjustable counterweight dam described in Embodiment 1 includes a base dam body 1 and a mobile dam 2 . The mobile dam 2 is movably arranged on the base plate, and under the impact of the debris flow, the mobile dam 2 is moved upwards, allowing more space to resist the debris flow and buffer the impact of the debris flow.

[0044] Wherein, the foundation dam body 1 is formed by pouring steel beams and concrete. The base dam body 1 is provided with a facing slope 11 and a backwater slope 12 corresponding to each other, and the cross section of the foundation dam body 1 is trapezoidal. The facing slope 11 is a side wall that bears the impact of debris flow, but its slope is relatively gentle, while the slope of the backwater slope 12 is relatively steep.

[0045] The mobile dam 2 is cast from steel beams and concrete with a strength higher than C40, and its bottom surface matches the water-facin...

Embodiment 2

[0052] Such as Figure 5 ~ Figure 7 As shown, the water cushion slope-shifting height adjustable counterweight dam described in Embodiment 2 is similar to the structure of Embodiment 1, the difference is that the supporting protrusion is specifically a rear wheel, and the guide rail 13 matches the Describe the rear wheel.

[0053] Specifically, two rear wheels are hinged at the bottom rear end of the mobile dam 2 through a steel shaft, and the rear wheels are embedded and hinged at the bottom of the mobile dam 2 . The rear wheel is placed in a prototype steel barrel through a steel beam, and poured concrete is solidified.

[0054] The water-facing slope 11 is recessed to form a set of guide rails 13 parallel to each other. The guide rail 13 matches the rear wheel, and the upward movement of the limit mobile dam 2 has a guiding effect on the rear wheel. The embedded rear wheel is combined with the concave guide rail 13, so that the bottom surface of the mobile dam 2 is more ...

Embodiment 3

[0057] Such as Figure 8 ~ Figure 9 As shown, the water cushion slope-shifting height adjustable counterweight dam described in Embodiment 3 is similar to the structure of Embodiment 1, the difference is that the water cushion chamber 21 of Embodiment 3 includes a front chamber 211 and a rear chamber 212 , the front chamber 211 communicates with the rear chamber 212 through a restrictor 213 .

[0058] Specifically, the middle part of the water pad container 21 protrudes to form a convex edge, and the convex edge separates the water pad container 21 into a front cavity 211 and a rear cavity 212 . The front chamber 211 and the rear chamber 212 are arranged side by side sequentially from the opening of the water cushion chamber 21 . The distance between the convex edge and the inner wall forms a restrictor opening 213 , so that the front chamber 211 communicates with the rear chamber 212 .

[0059] The opening of the front chamber 211 is the opening of the water cushion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com