Construction technology of lime-soil compaction piles in bridgehead road section in collapsible loess area

A technology for lime-soil compaction piles and collapsible loess, which is applied in soil protection, infrastructure engineering, construction and other directions, and can solve problems such as technical difficulties in the construction of lime-soil compaction piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] 【Example】

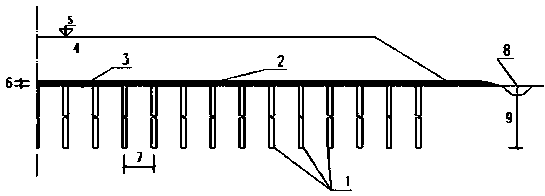

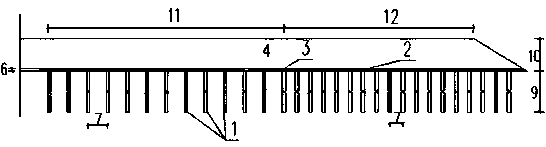

[0020] The foundation treatment measures of lime-soil compaction piles (1) are adopted for the bridge head section with high filling height, settlement that does not meet the requirements, and soil collapsibility, plum blossom-shaped layout, and lime-soil compaction piles (1). The pile diameter is 300mm, and the pile spacing is general The pile length is 0.9~1.1m, the pile length is 10m and 13m, and the treatment length is 3 times the height of the bridgehead subgrade filling + 20m transition section (11). Determine the construction technical parameters of the lime-soil compaction pile (1) according to the design requirements: 1. pile diameter D ;Pile length(9) h ;2. Lime-soil ratio: 3:7 (volume ratio); 3. Spacing: 0.9m and 1.1m, arranged in plum blossom shape; 4. Hole forming and compaction are all done by machinery; 5. Material re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com