The main furnace of the biomass evaporator

An evaporator and biomass technology, applied in steam boilers, steam generation, steam separation devices, etc., can solve problems such as high water content in steam, and achieve the effects of improving utilization, reducing kinetic energy, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

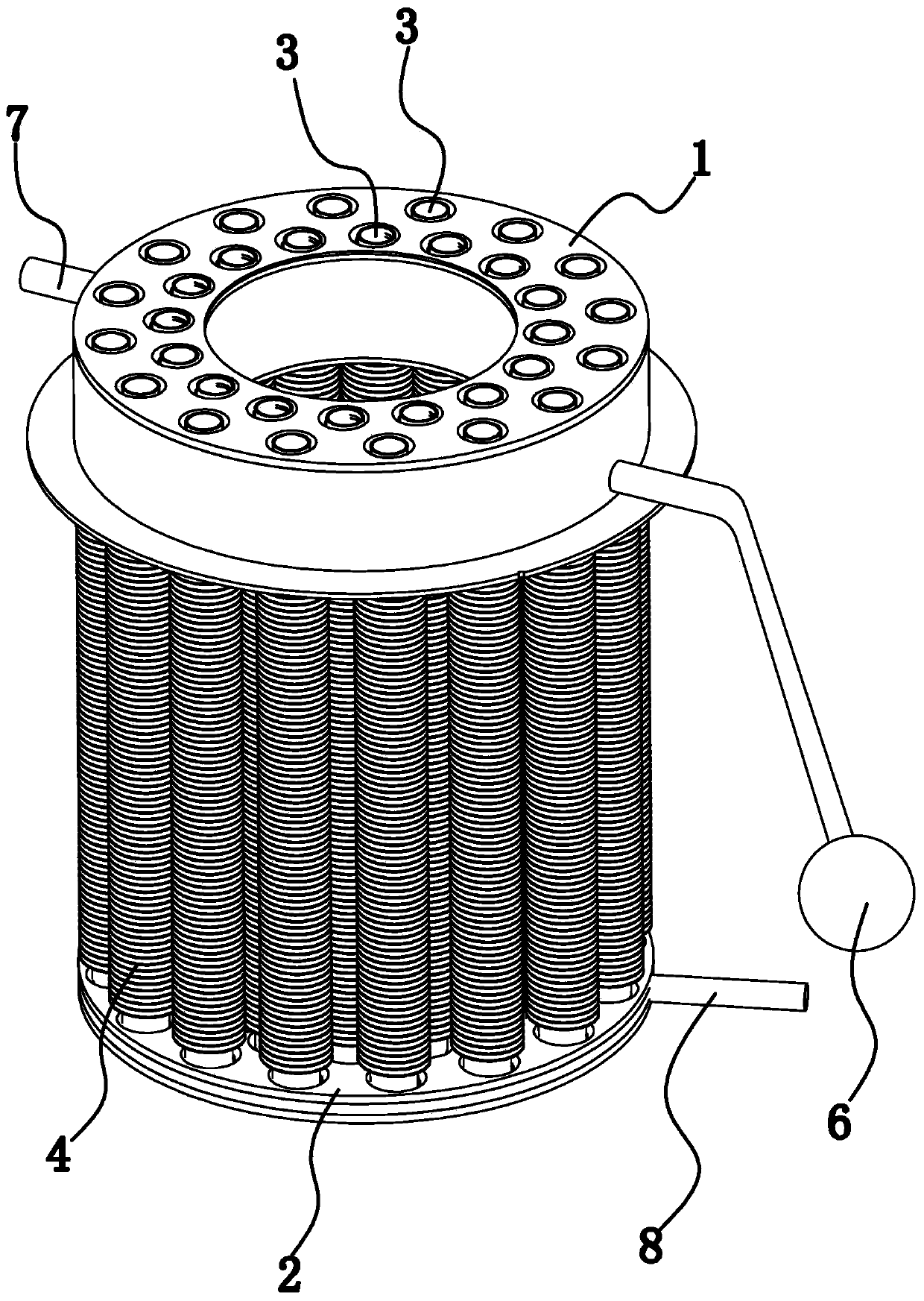

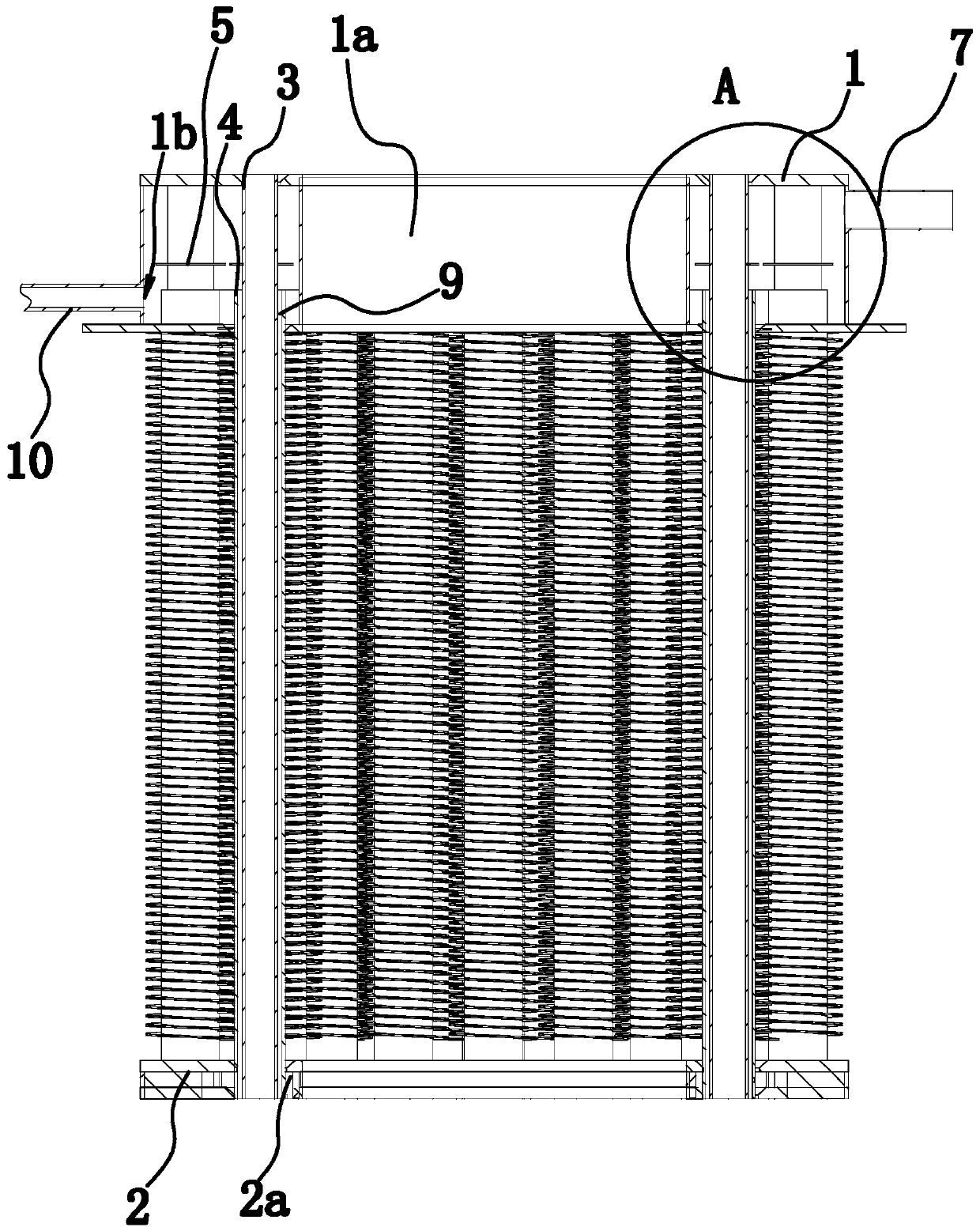

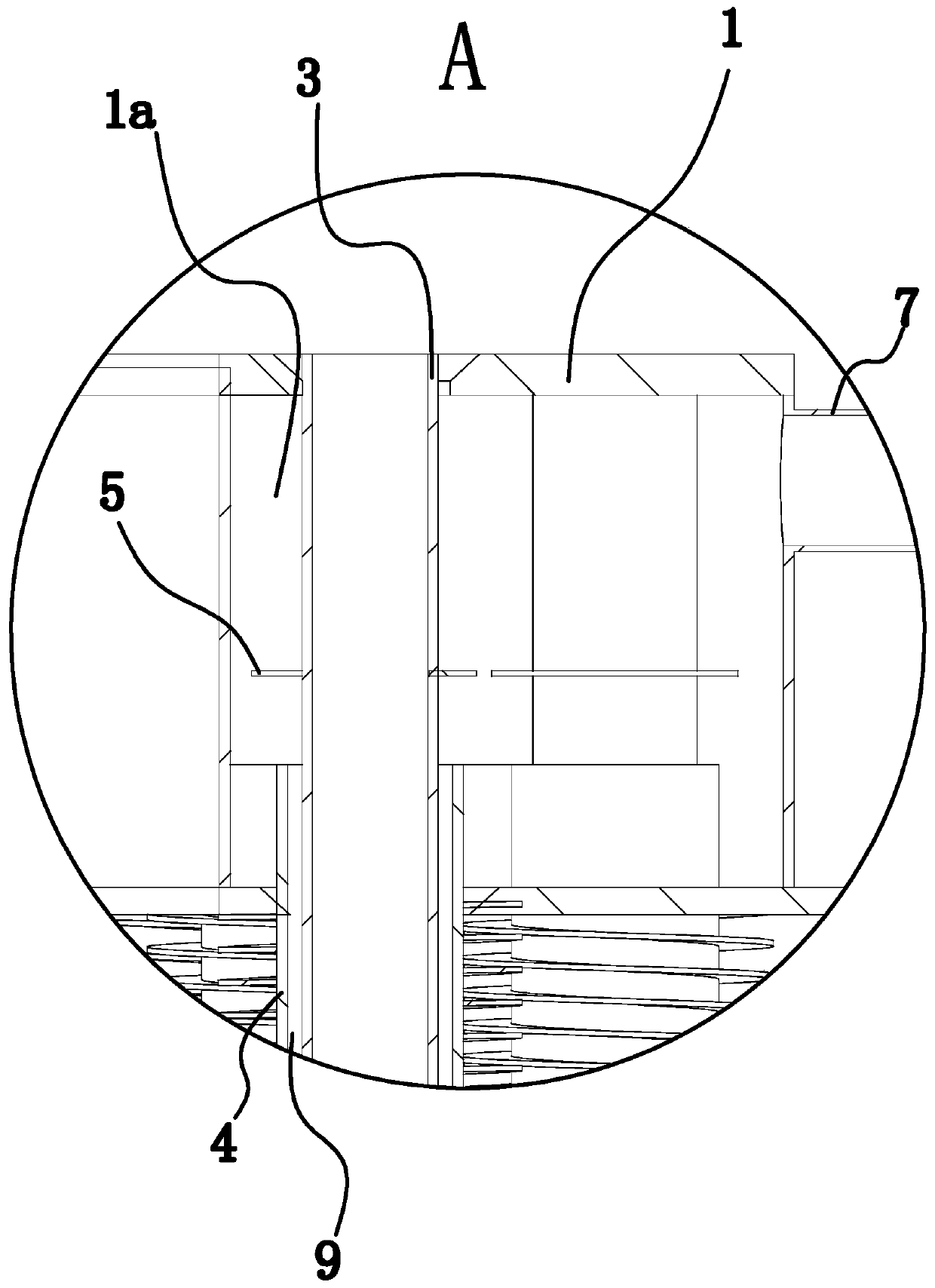

[0031] Such as Figure 1 to Figure 5 As shown, the main furnace of the biomass evaporator is composed of an upper support 1, a lower support 2, a heat conducting tube 3, a finned tube 4, a water retaining ring 5, a water pump 6 and the like. Wherein, the heat pipe 3 is made of a heat conducting material, and the heat conducting material may be brass, stainless steel or the like.

[0032] Specifically, the upper support 1 has an air collection chamber 1a inside, and an exhaust port is opened on the side wall of the upper support 1 to communicate the air collection chamber 1a with the outside world. The lower support 2 has a water collection cavity 2a inside, and a water inlet for communicating the water collection cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com