Self-packaging method of sheet-shaped flexible piezoresistive sensor

A piezoresistive sensor and self-encapsulation technology, applied in the field of sensors, can solve problems such as poor mobility and wearability, affect component life, and poor stability, and achieve novel and simple preparation methods, prolong service life, and maintain stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

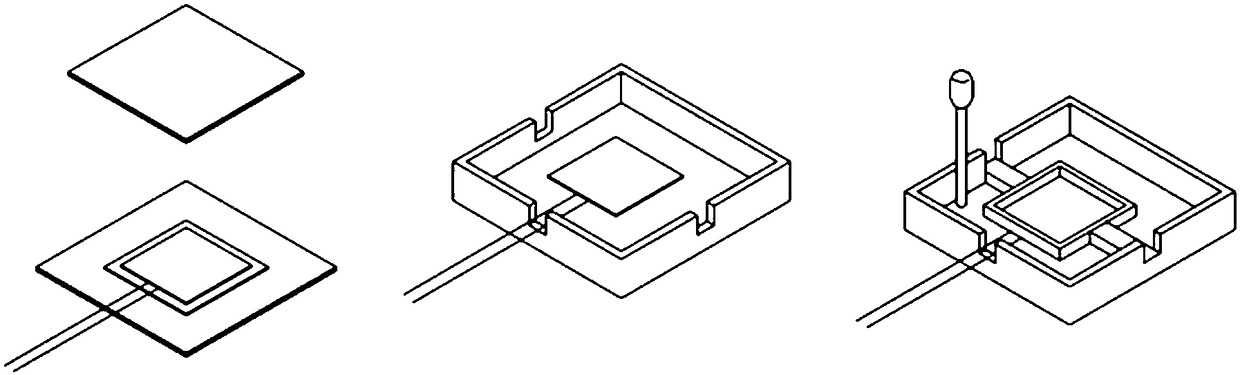

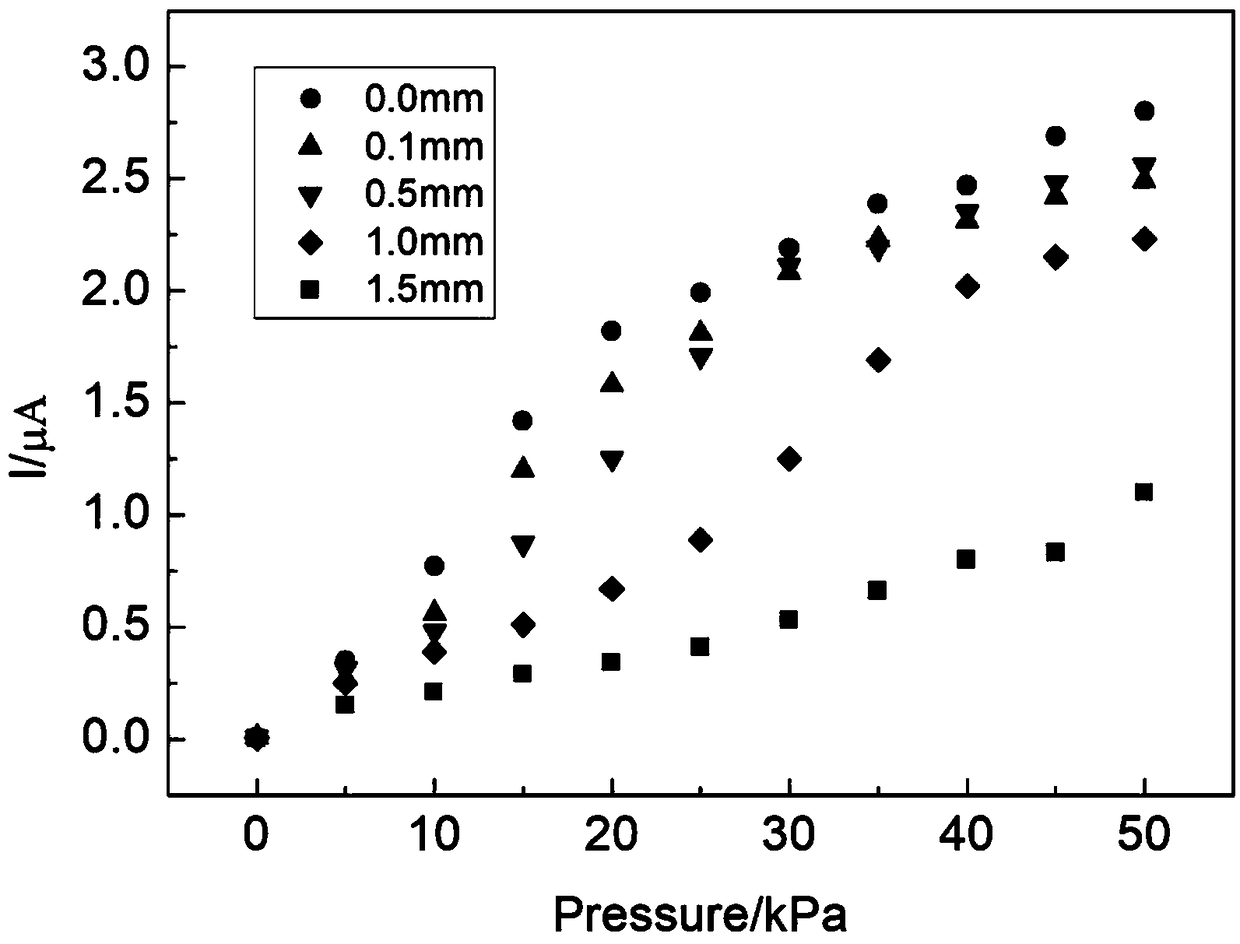

[0017] Embodiment 1: based on a sensor package with a film thickness of 0.10 mm.

[0018] Concrete preparation is carried out as follows:

[0019] 1. Prepare two layers of Ecoflex films with a thickness of 0.10mm by using the rotary glue method, and the rotation speed is 200 rpm; the length and width of the smaller ones are: 30mm and 20mm; the length and width of the larger ones are 40mm and 30mm;

[0020] 2. Use 3D printing to prepare a mold of appropriate size, including the tank and the card frame;

[0021] 3. Place the sensor between two layers of film to form a sandwich structure and place it in the tank;

[0022] 4. Tighten the card frame, inject the pre-prepared Ecoflex solution into the gap between the card frame and the reservoir with a rubber dropper or syringe;

[0023] 5. Keep warm at 60°C for a period of time to complete the package, and the final package thickness is 0.22mm.

Embodiment 2

[0024] Embodiment 2: Based on the sensor package with a film thickness of 0.50 mm.

[0025] Concrete preparation is carried out as follows:

[0026] 1. Prepare two layers of Ecoflex films with a thickness of 0.50mm by using the rotary coating method, and the rotation speed is 150 rpm; the length and width of the smaller ones are: 30mm and 20mm; the length and width of the larger ones are 40mm and 30mm;

[0027] 2. Use 3D printing to prepare a mold of appropriate size, including the tank and the card frame;

[0028] 3. Place the sensor between two layers of film to form a sandwich structure and place it in the tank;

[0029] 4. Tighten the card frame, inject the pre-prepared Ecoflex solution into the gap between the card frame and the reservoir with a rubber dropper or syringe;

[0030] 5. Keep warm at 60°C for a period of time to complete the package, and the final package thickness is 0.11mm.

Embodiment 3

[0031] Embodiment 3: based on a sensor package with a film thickness of 1.0 mm.

[0032] Concrete preparation is carried out as follows:

[0033] 1. Prepare two layers of Ecoflex films with a thickness of 1.0mm by using the rotary coating method, and the rotation speed is 100 rpm; the length and width of the smaller ones are: 30mm and 20mm; the length and width of the larger ones are 40mm and 30mm;

[0034] 2. Use 3D printing to prepare a mold of appropriate size, including the tank and the card frame;

[0035] 3. Place the sensor between two layers of film to form a sandwich structure and place it in the tank;

[0036] 4. Tighten the card frame, inject the pre-prepared Ecoflex solution into the gap between the card frame and the reservoir with a rubber dropper or syringe;

[0037] 5. Keep warm at 60°C for a period of time to complete the package, and the final package thickness is 2.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com