Test device and test method for testing performance of fiber composite grid material

A technology of material properties and testing devices, applied in the direction of measuring devices, analysis materials, preparation of test samples, etc., can solve the influence of the inability to test the strength of composite mesh materials, and the inability to fully reflect the composite mesh, etc. problems, achieve the effect of reducing the overall weight, strong operability and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

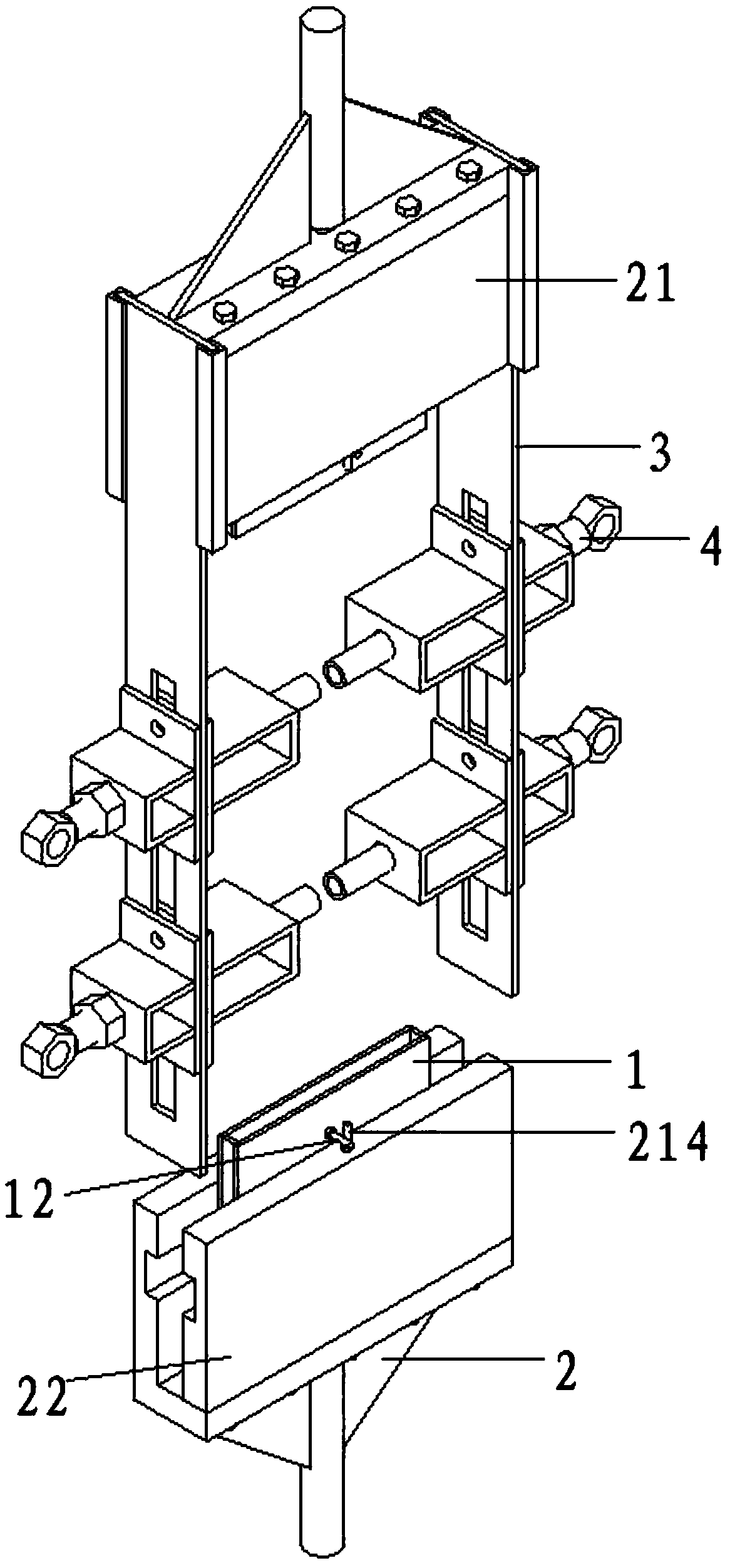

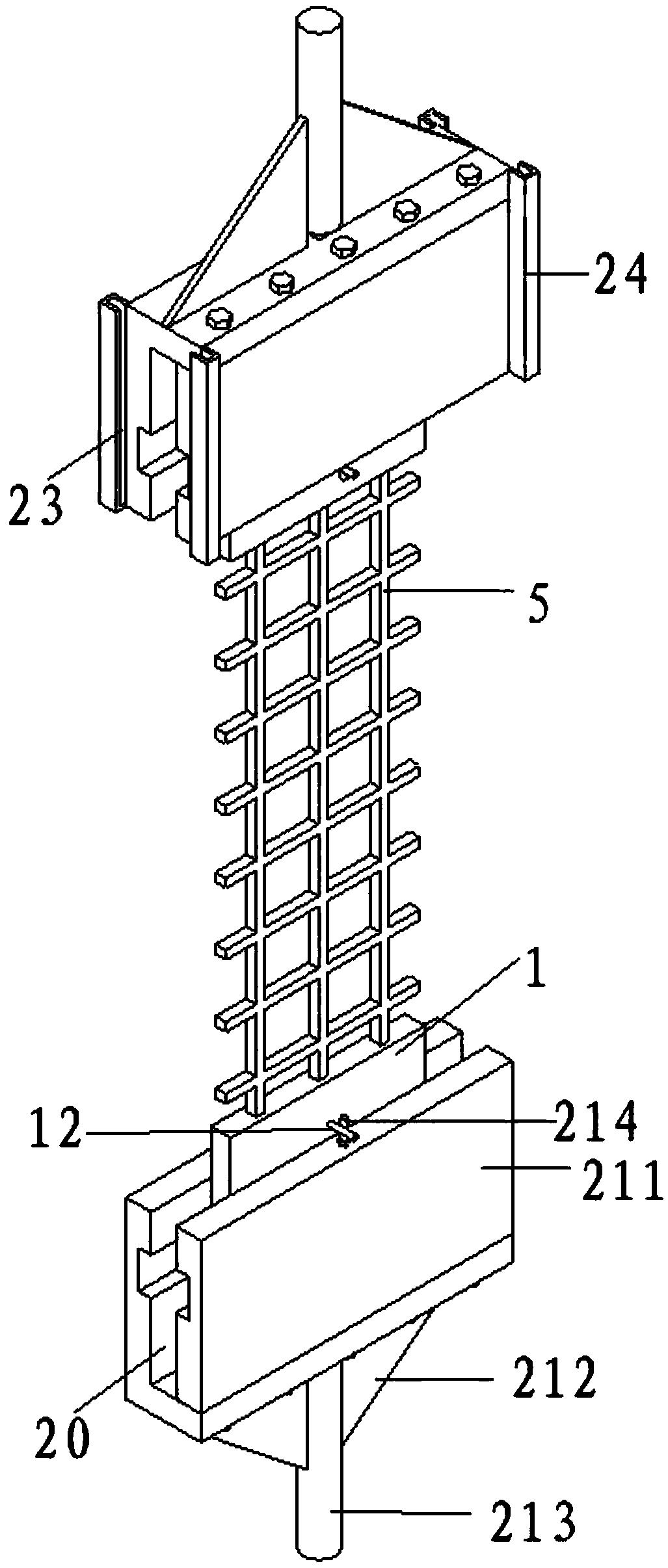

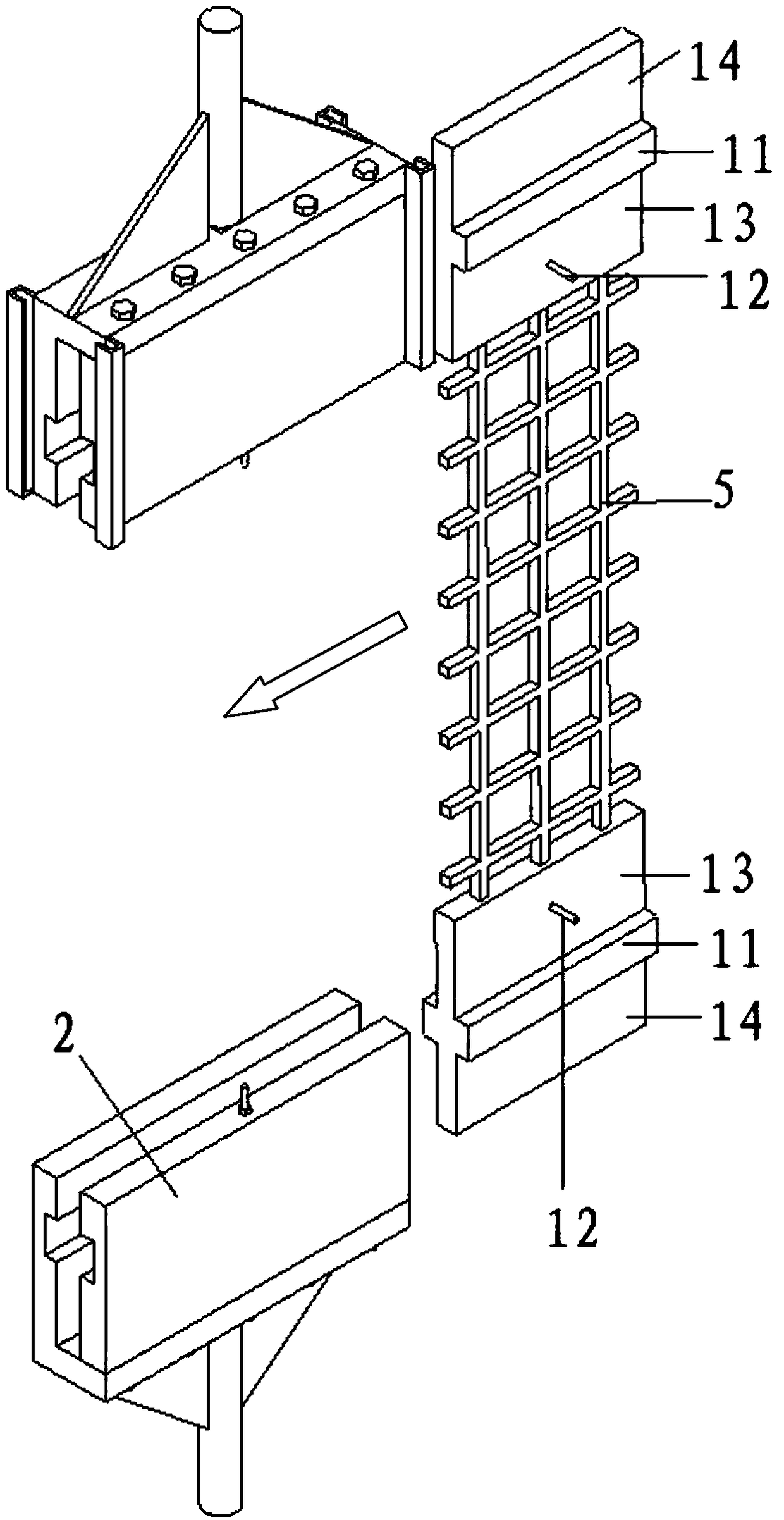

[0045] refer to Figure 1-2 , Embodiment 1 of the present invention discloses a test device for the performance of a fiber composite grid material, a composite grid fixture 1 and a clamping device 2; the clamping device 2 includes: an upper pair of pulling clamping devices 21 and a lower pair of clamping devices The pull clamping device 22, the upper pair of pull clamping device 21 and the lower pair of pull clamp device 22 are all provided with a chute-20, and the composite grid clamp 1 is connected with the upper pair of pull clamp device 21 and the lower pair of pull clamp device 20 through the chute-20 respectively. The lower clamping device 22 is slidingly connected; the top end of the upper clamping device 21 and the bottom end of the lower clamping device 22 are respectively clamped and connected with the upper and lower beams of the universal testing machine; between the composite grid clamps 1 Standard parts 5 are provided.

[0046] In order to further optimize the a...

Embodiment 2

[0056] refer to Figure 5 , Embodiment 2 of the present invention discloses a test device for the performance of a fiber composite grid material. On the basis of Embodiment 1, it also includes: 2 slidable steel plates 3 and 2 transverse rib fixing devices 4, which can The sliding steel plate 3 is arranged on both sides of the upper pair of clamping devices 21; the middle part of the sliding steel plate 3 is provided with a chute 2 31; the transverse rib fixing device 4 slides at any position on the chute 2 31 through the connector, and The transverse rib is fixedly connected with the slidable steel plate 3 through the connecting piece after the position of the second chute 31 is determined. The transverse ribs and nodes are constrained by the slidable steel plate 3 and the transverse rib fixing device 4, so as to realize the testing of the node strength and the influence of the node strength on the strength of the composite grid material.

[0057] In order to further optimize...

Embodiment 3

[0066] refer to Figure 9 , Embodiment 3 of the present invention discloses a test device for the performance of a fiber composite mesh material. On the basis of Embodiment 2, two transverse rib fixing devices are added and arranged oppositely.

[0067] refer to Figure 10-12 , the test method of embodiment 3 disclosed by the invention is:

[0068] Include the following steps:

[0069] S1. Select the appropriate steel plate to be welded as the composite grid fixture according to the grid size of the composite material and the type of test;

[0070] S2. Cut the composite material grid sample to be tested into a standard size to make a standard part. At least one end of the standard part is inserted into the center of the composite material grid fixture, and the glue is injected and anchored. After the glue is solidified, the composite material Grid fixture and standard parts become one;

[0071] S3. Slide the composite grid jig into the corresponding clamping device, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com