Oil-gas field water scaling tendency predicting system and method

A prediction system and technology for oil and gas fields, applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problems of sample deterioration, affecting prediction accuracy, and many influencing factors, etc. Achieve the effect of preventing errors and human errors, improving reliability and real-time performance, and improving real-time performance and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a system and method for predicting scaling tendency of oil and gas field water. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

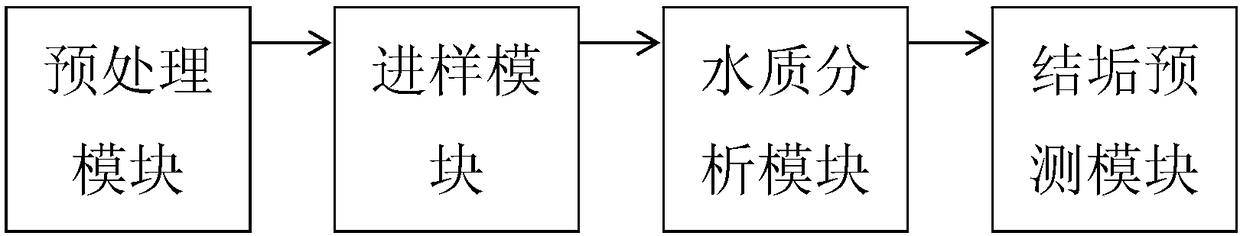

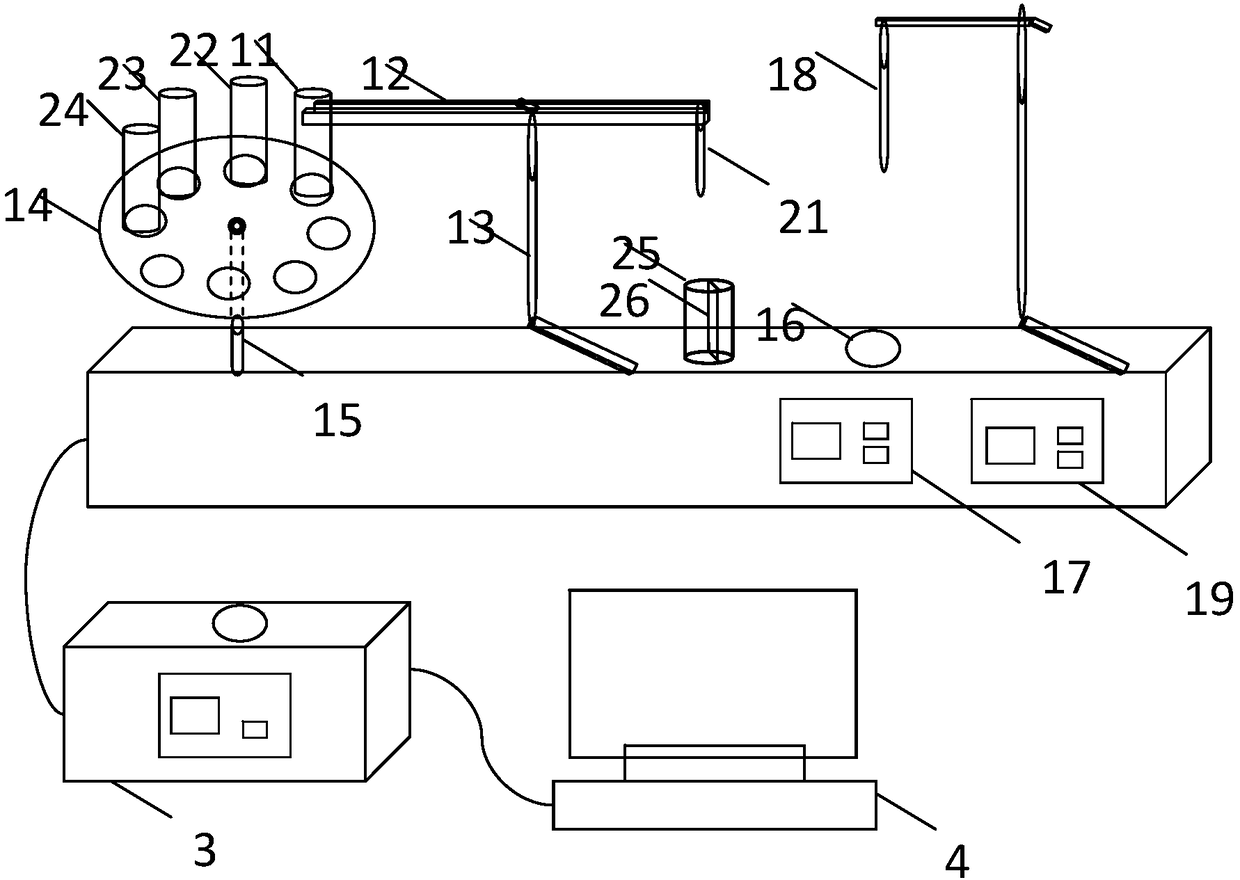

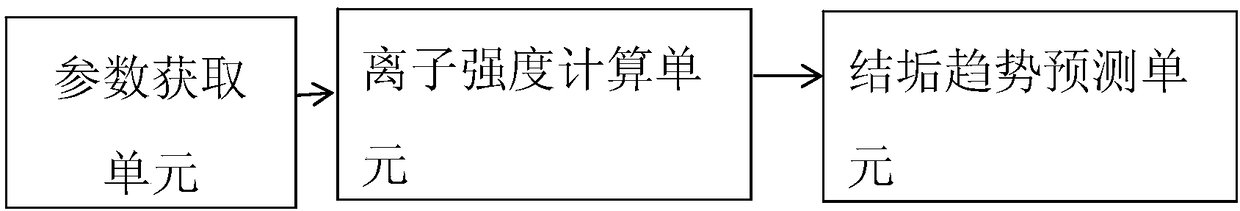

[0030] The invention provides a system for predicting the scaling trend of oil and gas field water, such as figure 1 , figure 2 and image 3 As shown, it includes a placement platform, wherein, the placement platform is provided with a sample pretreatment module, a sample injection module, a water quality analysis module 3 and a scaling prediction module 4; and the sample pretreatment module is used to perform on-site water samples Homogenization and impurity removal treatment; the sampling module is used to collect water samples on site ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com