Alkaline stripping solution for photoresists

A technology of photoresist and stripping solution, which is applied in the field of microelectronics, can solve the problems of rear Ti/Ni/Ag oxidation, white spots, and chromatic aberration, and achieve the effect of preventing white spots and chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

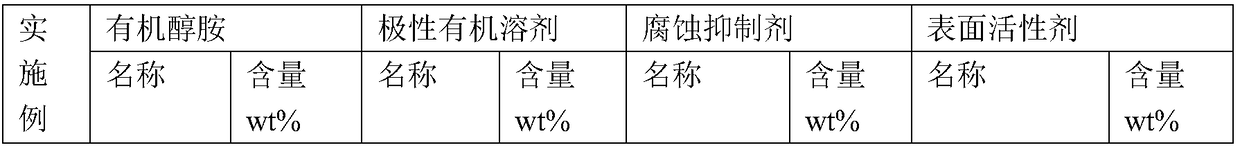

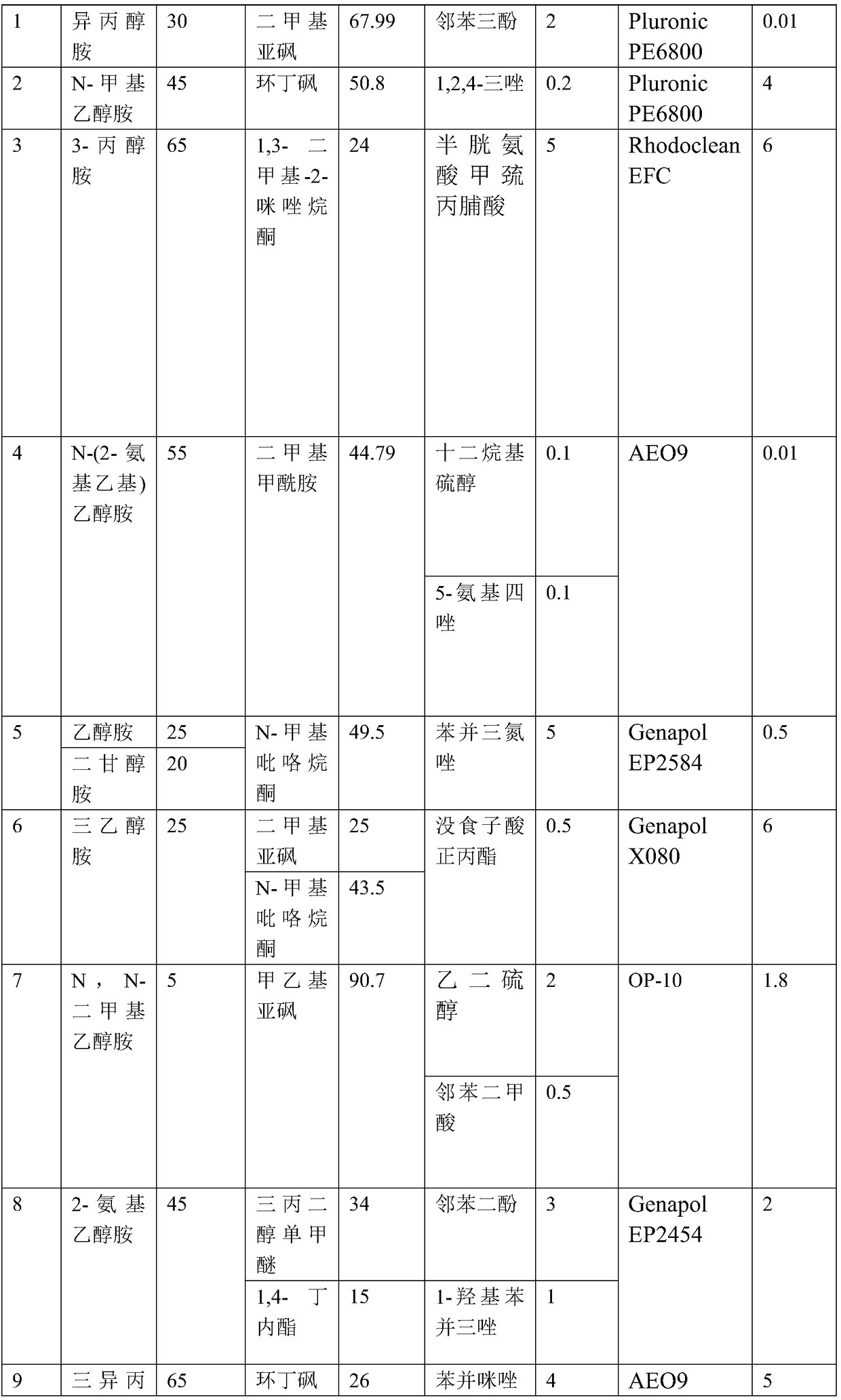

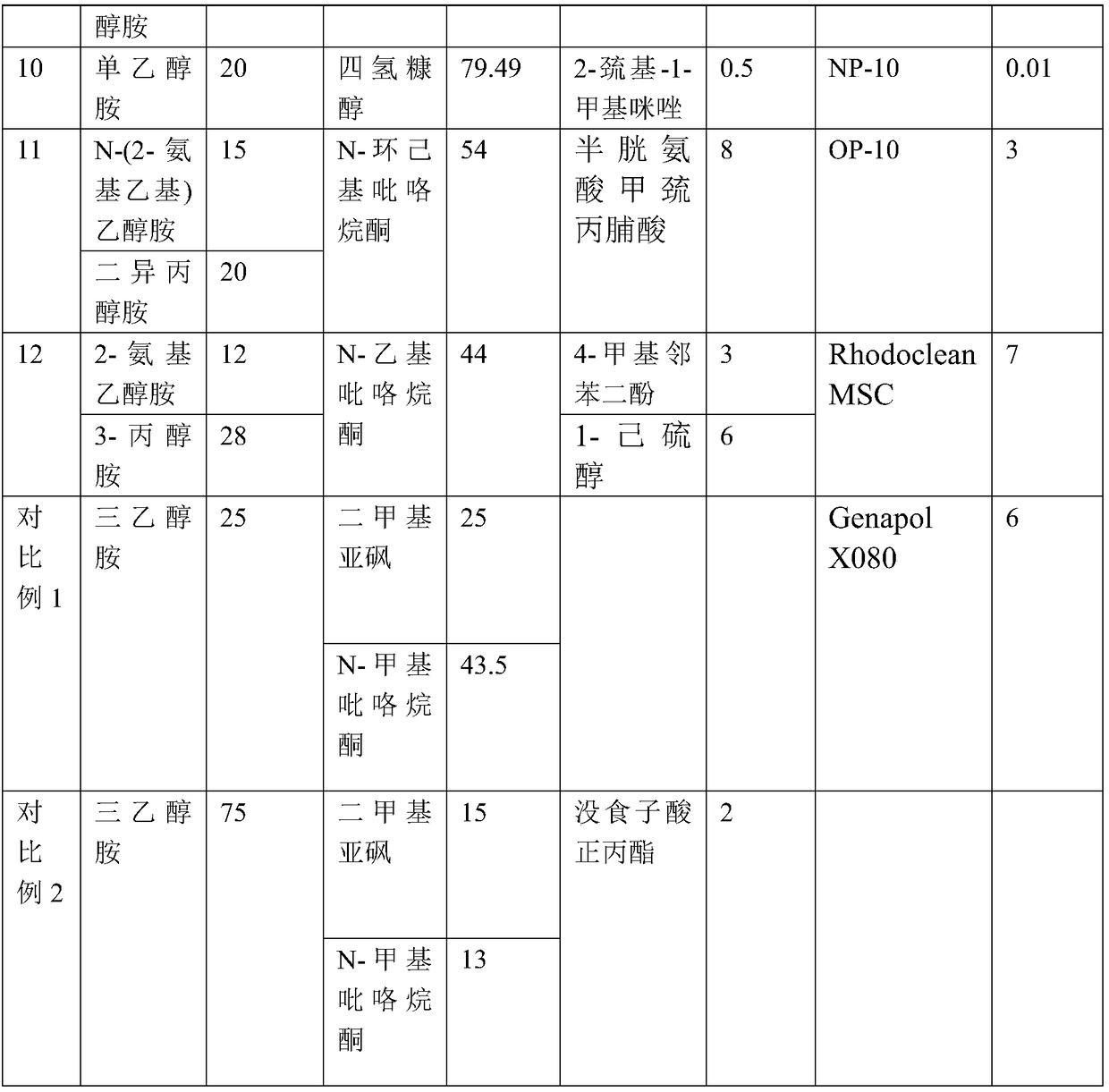

[0027] Component and content of table 1 embodiment and comparative example cleaning solution:

[0028] Table 1

[0029]

[0030]

[0031]

[0032] In order to further investigate the implementation effect of the photoresist stripping solution, the present invention adopts the following technical means: the 6-inch power semiconductor wafer chip whose back gold is Ti / Ni / Ag is cut into coupon wafers of 2cm*5cm, the wafer The front side has been patterned and transferred by the photolithography process. The coupon wafers are respectively immersed in the photoresist stripping solution, soaked at 30°C to 90°C for 3-30min, rinsed and dried with high-purity nitrogen. Then vacuum annealing is carried out in a vacuum sintering furnace at 350°C, the cleaning effect of the photores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com