Method of manufacturing semiconductor device, substrate processing apparatus and recording medium

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electrical components, etc., can solve the problem of signal transmission speed reduction and achieve good characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] Hereinafter, an embodiment of the present invention will be described.

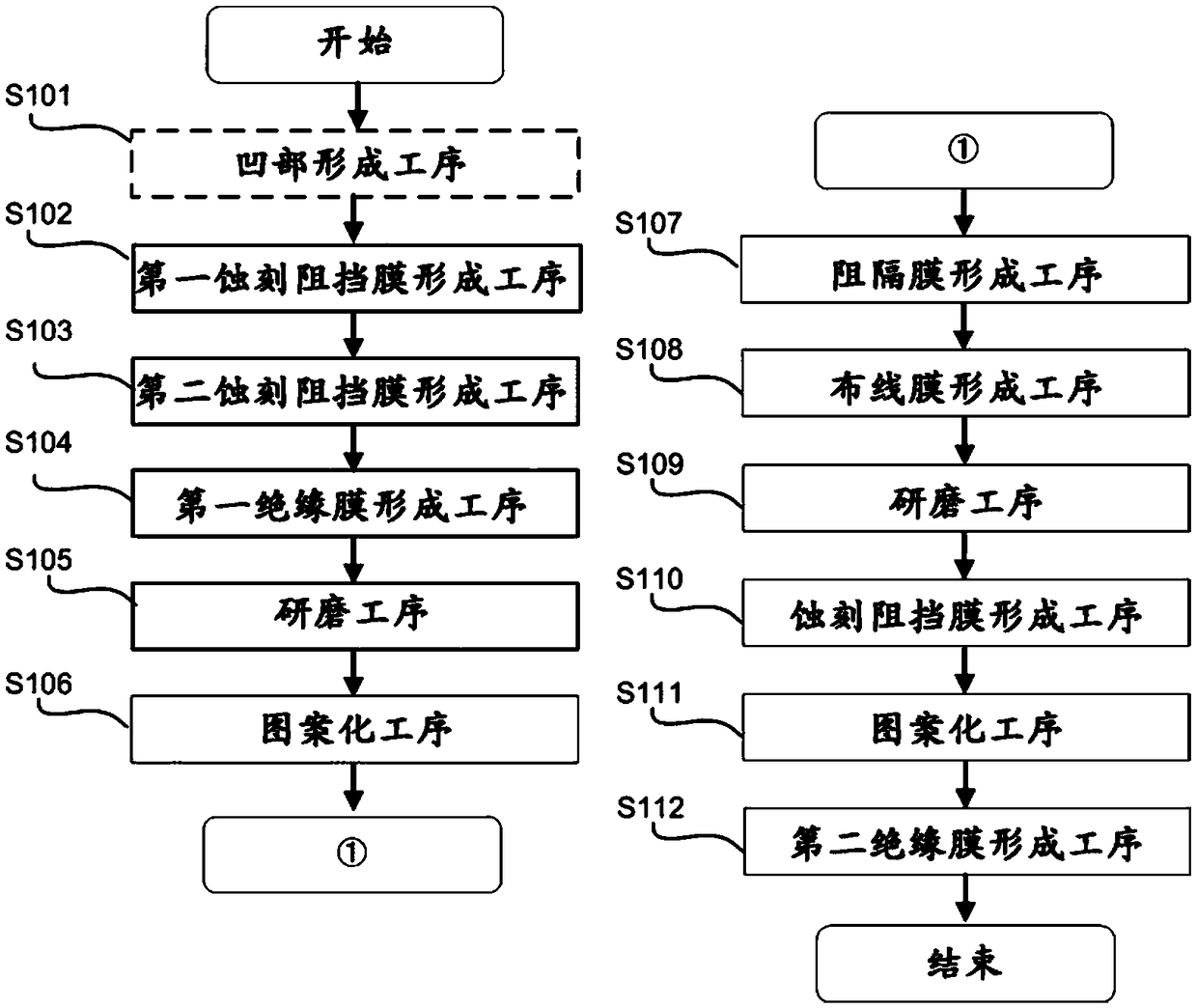

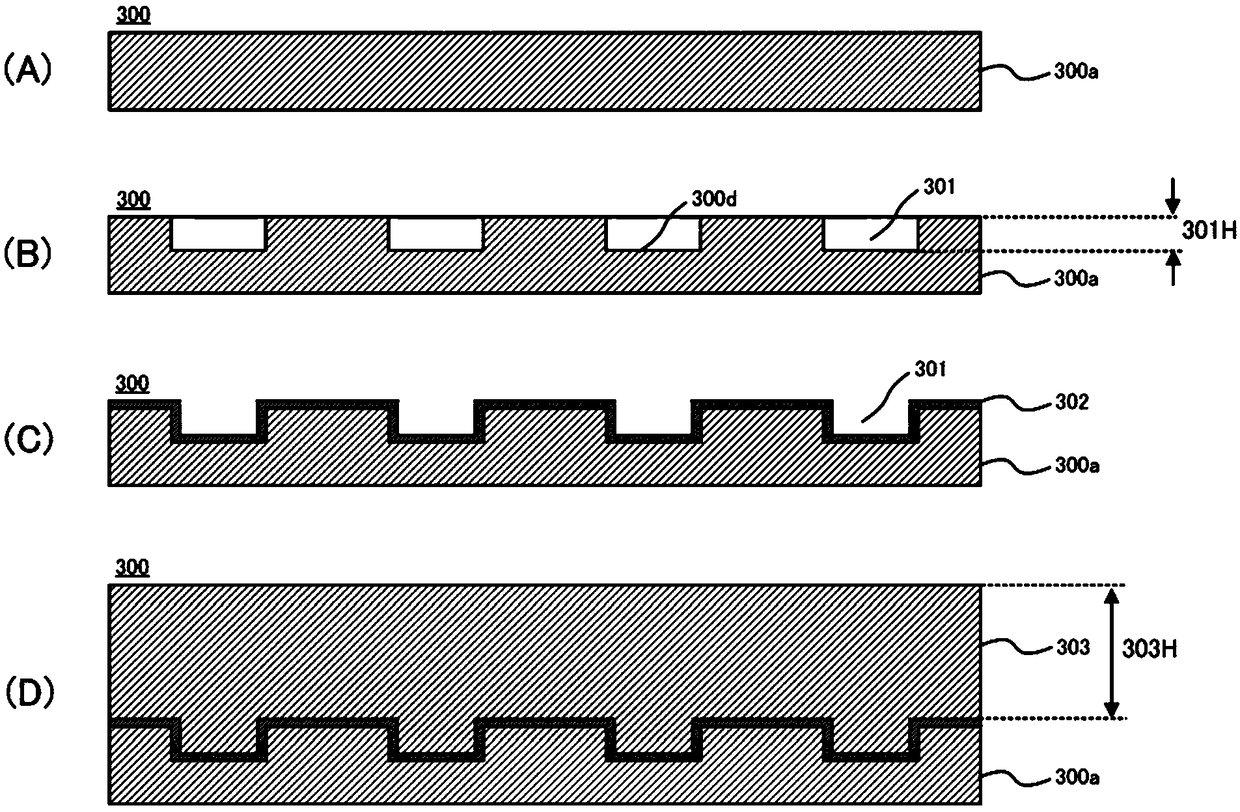

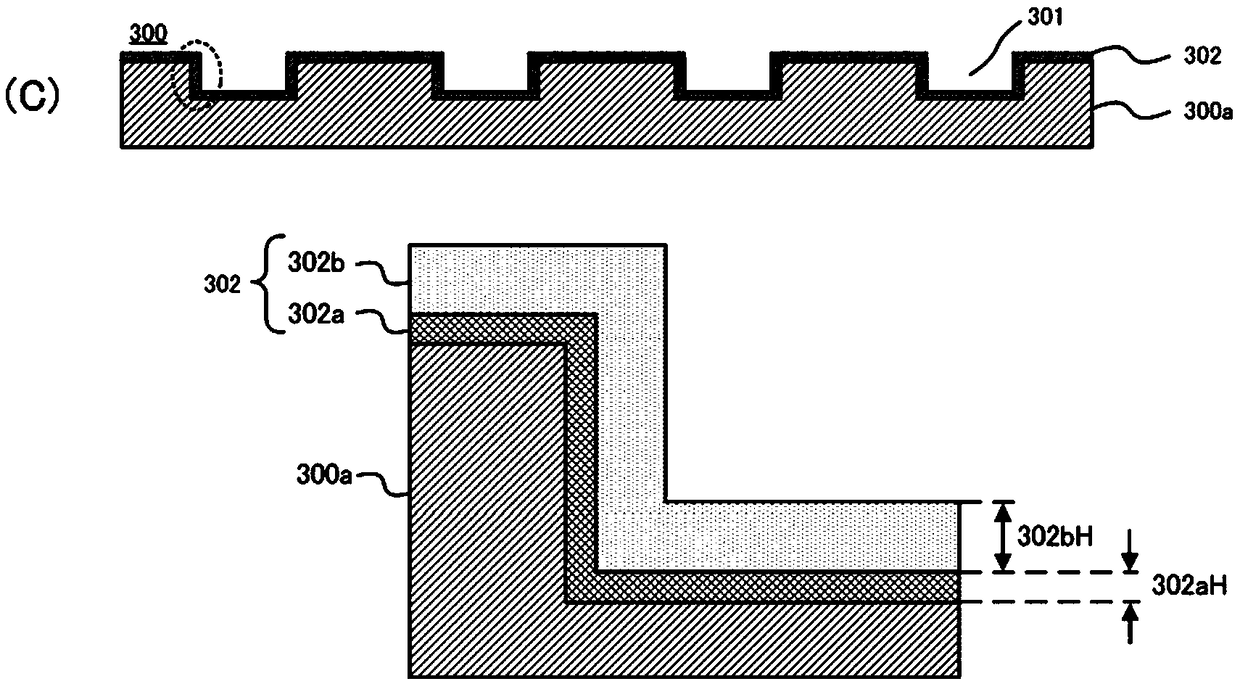

[0031] use Figure 1 ~ Figure 6 , Describe a step of the manufacturing process of a semiconductor device. figure 1 Is a flowchart of the manufacturing process of a semiconductor device, Figure 2 ~ Figure 6 To show and figure 1 The state of the substrate corresponding to each process.

[0032] (Depression forming step S101)

[0033] The recess forming step S101 will be described.

[0034] Regarding the recess forming step S101, use figure 2 (A) and (B) are explained. The first recess 301 is formed on the surface of the surface layer 300 a of the substrate 300. The surface layer 300a is composed of either or both of the insulating film and the Si substrate. The insulating film is, for example, a silicon oxide film (SiOC film) containing carbon. The first recess 301 is formed by a patterning technique. Here, the height (depth) 301H of the recess is formed to be larger than the total film thickness (302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com