A thermal battery internal temperature control structure

A technology of internal temperature and control structure, applied in the field of internal temperature control structure of thermal batteries, to achieve the effect of broadening the range of usage, enhancing safety performance, and broadening the scope of thermal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

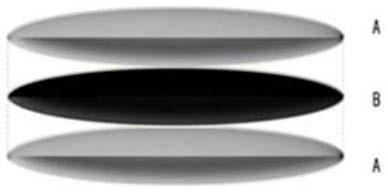

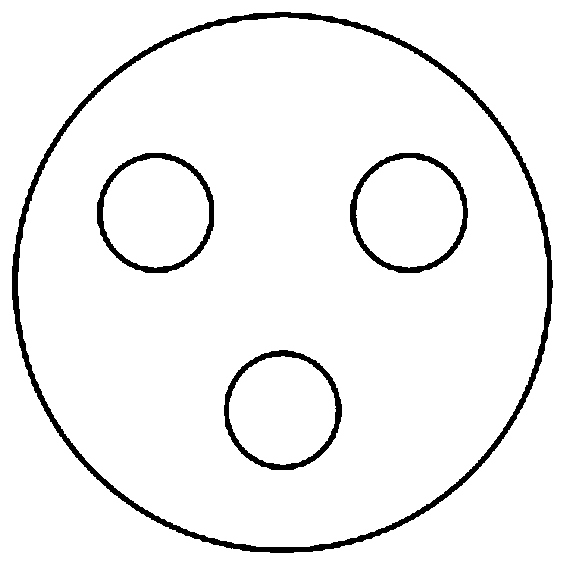

[0027] Embodiment 1, a new thermal battery internal temperature control structure: refer to the attached figure 1 , image 3 , Figure 5 and Image 6 , the temperature control body is composed of insulating and heat-insulating layer A, heat-absorbing layer B and insulating and heat-insulating layer A. The insulating and heat-insulating layer A is composed of multiple asbestos sheets with a thickness of 3mm. The heat-absorbing layer is composed of graphite sheets with a thickness of 10mm. , the heat-absorbing layer B is close to the insulating and heat-insulating layer A up and down, and the insulating and heat-insulating layer A and the heat-absorbing layer B are both through-hole structures, forming a structure such as figure 1 A single typical sandwich body shown, then press Figure 5 shown in series assembly or Image 6 The parallel assembly shown is installed in the heat concentrated part of the battery.

Embodiment 2

[0028] Embodiment 2, a new thermal battery internal temperature control structure: refer to the attached figure 1 , figure 2 , Figure 4 , Figure 5 and Image 6 , the temperature control layer is composed of insulation layer A, heat absorption layer B and insulation layer A to form a sandwich body, insulation layer A is composed of aerogel, with a thickness of 3 mm, and the heat absorption layer is composed of metal phase change materials, thick 1mm, the heat-absorbing layer B is close to the insulation layer A up and down, and the insulation layer A and the heat-absorbing layer B are both solid structures. figure 1 The single typical sandwich body shown is composed of several such structures spliced up and down, such as figure 2 Multi-sandwich as shown, press Figure 5 shown in series assembly or Image 6 The parallel assembly shown is installed in the heat concentrated part of the battery.

Embodiment 3

[0029] Embodiment 3, a new thermal battery internal temperature control structure: refer to the attached figure 1 , figure 2 , image 3 , Figure 5 and Image 6 , the temperature control layer is composed of insulation layer A, heat absorption layer B and insulation layer A to form a sandwich body, insulation layer A is composed of mica sheet and asbestos gasket, the thickness of mica sheet is 0.1mm, and the thickness of asbestos gasket is 0.3mm, the total thickness of the insulation layer A is 0.7mm, the heat absorption layer B is composed of phase change molten salt material, the thickness is 1mm, the heat absorption layer B is close to the insulation layer, the insulation layer A and the heat absorption layer B Both are through-hole-like structures, which are first formed as figure 1 The single typical sandwich body shown is composed of several such structures spliced up and down, such as figure 2 Multi-sandwich as shown, press Figure 5 shown in series assembly o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com