Cylindrical battery cell film-making and winding machine

A cylindrical, winding machine technology, applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, circuit, etc., can solve the problems of short circuit detection time, too tight cell compaction, slow response of cylinder action, etc. Achieve the effect of improving the response speed, preventing the cell from falling, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

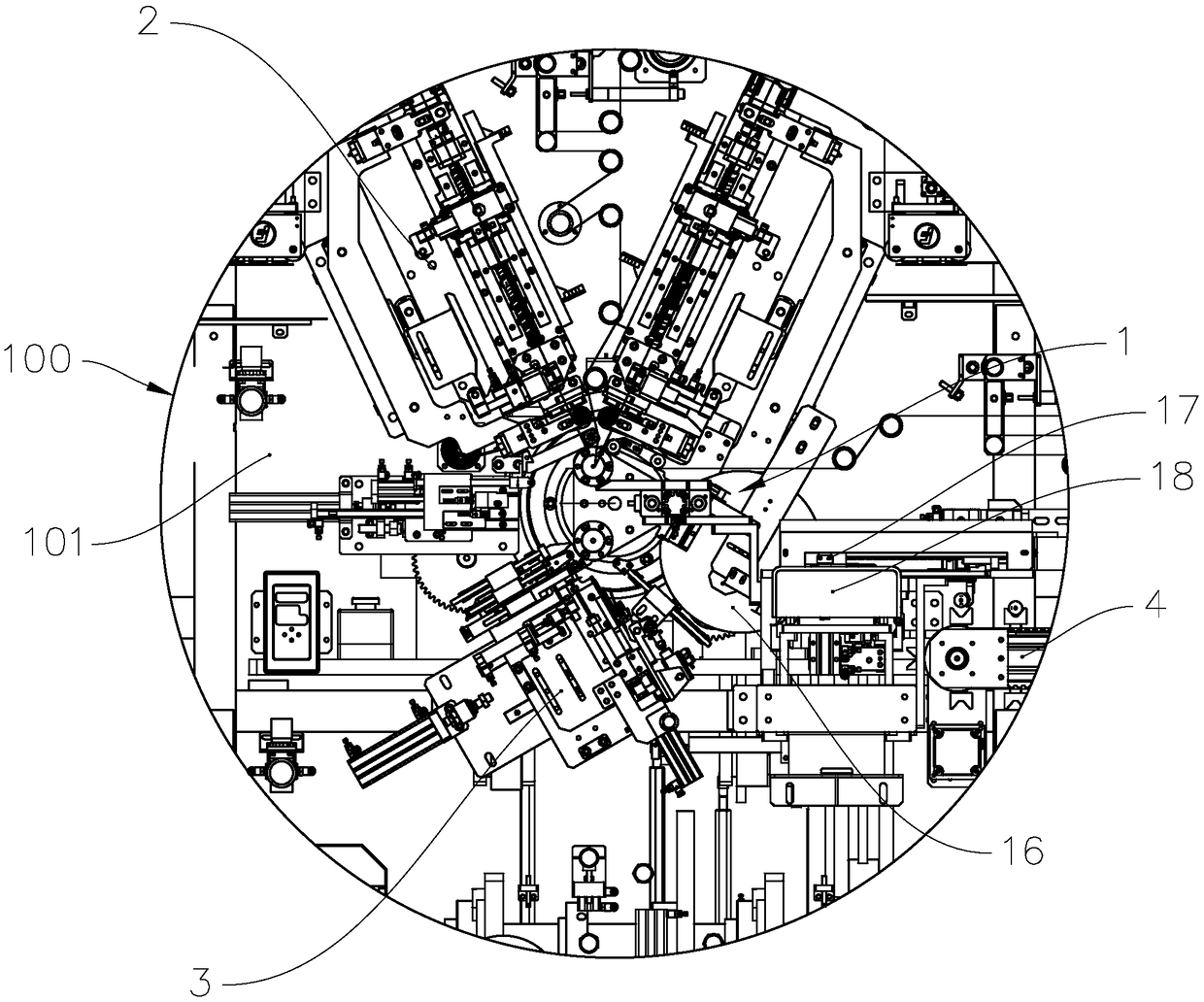

[0044] refer to Figure 1 to Figure 3 , the cylindrical battery sheet winding machine 100 includes a frame 101, a winding head device 1, a pole piece insertion cutting device 2, a gluing device 3 and a battery short circuit test device 4, wherein the pole piece insertion cutting device 2. The gluing device 3 , the cell short-circuit testing device 4 , and the winding head device 1 are all fixedly connected to the frame 101 .

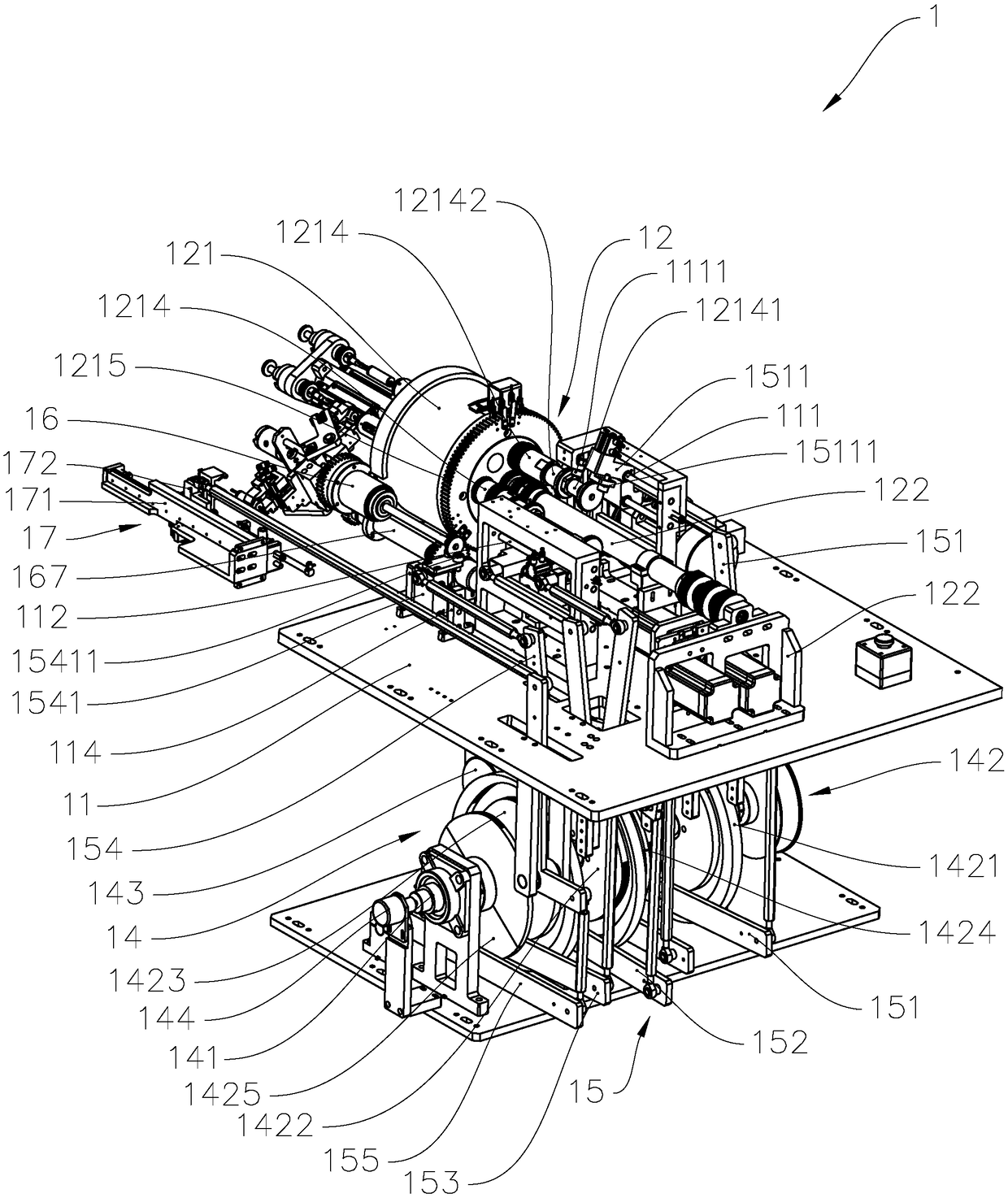

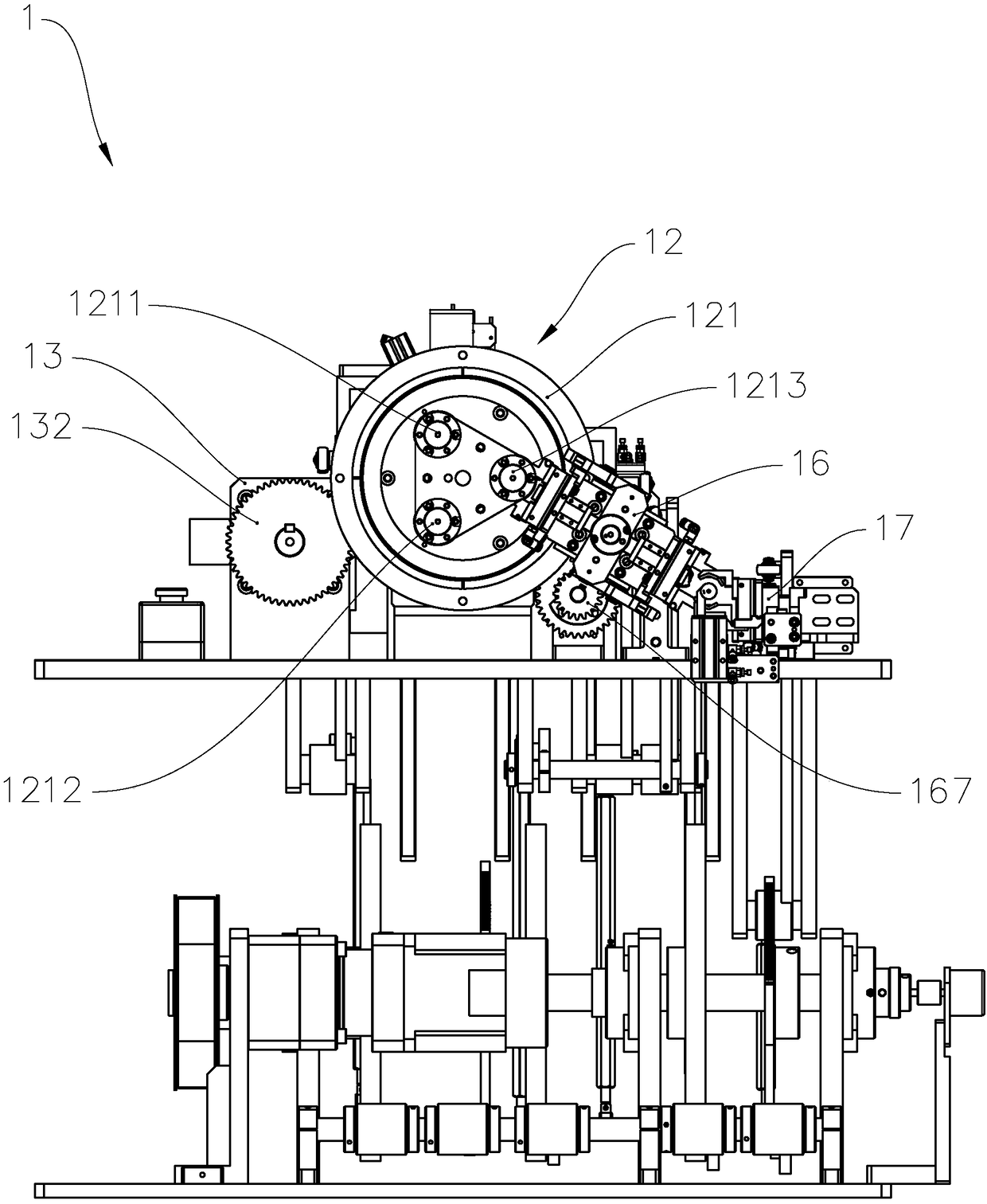

[0045] Specifically, the winding head device 1 includes a first mounting seat 11, a winding unit 12, a reversing unit 13, a first driving unit 14, a swing arm group unit 15, a cell blanking unit 16, and a cell moving unit 17. And hot hole unit 18. The first mounting base 11 is fixedly connected to the frame 101 . The winding unit 12 includes a winding head 121 and a drive mechanism 122, the winding head 121 is rotatably connected with the first mount 11 around its own axis, the winding head 121 includes a first station 1211, a second station 1212 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com