Water-borne lithium ion battery and preparation method thereof

A lithium-ion battery, water-based electrolyte technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy fire and explosion of batteries, low ion migration rate, inability to use water-based electrolytes, etc., and achieve high rate performance improvement , to meet the needs of high voltage, to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Further, the present invention also provides a method for preparing the above-mentioned aqueous lithium-ion battery, the method comprising the following steps:

[0023] (1) Coating an organic solid electrolyte on the surface of the negative electrode, the mass ratio of the active material of the negative electrode to the organic solid electrolyte is 100:0.5~40, preferably 100:0.5~20, for example 100:0.5, 100:5 , 100:10, 100:20; use a semi-permeable membrane to completely cover and seal the negative electrode sheet;

[0024] (2) After step (1) is completed, it is wound with the positive electrode sheet, put into the shell, and injected with tris(trifluoro Methylsulfonyl) methyllithium aqueous solution to make lithium-ion batteries.

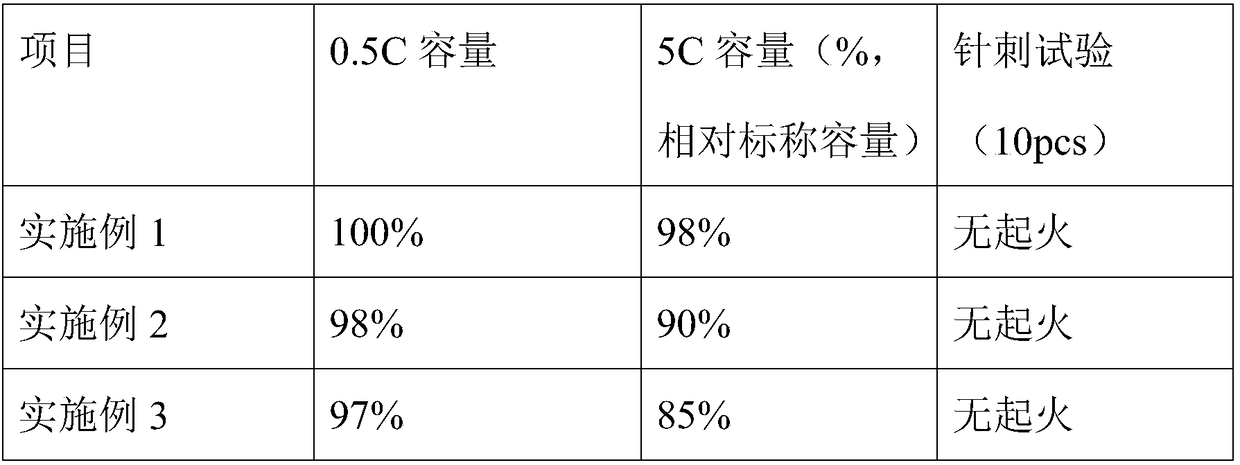

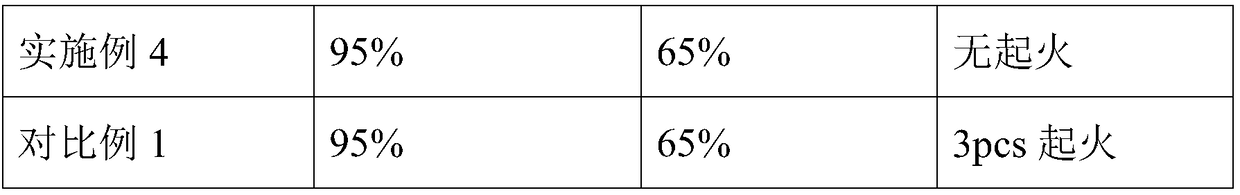

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments. The following examples are only to illustrate and explain the present invention, but should not be ...

Embodiment 1

[0028] Coating a solid electrolyte on the surface of the negative electrode, negative electrode active material (graphite): organic solid electrolyte (the composition of the organic solid electrolyte is: the solute is lithium hexafluorophosphate, the solvent is a mixed solution of PC: EC: DEC = 1: 1: 1, Among them, the concentration of lithium hexafluorophosphate is 1mol / L)=100:0.5, the pole piece is completely covered and sealed with a collodion film, and then it is wound with the positive pole piece, put into the shell, and injected with 1mol / L tri(trifluoromethylsulfur Acyl) methyl lithium aqueous solution to make 18650 2000mAh battery.

Embodiment 2

[0030] Coat the solid electrolyte solution on the surface of the negative electrode, negative electrode active material (hard carbon): organic solid electrolyte solution (the composition of the organic solid electrolyte solution is: the solute is lithium hexafluorophosphate, and the solvent is a mixed solution of PC: EC: DEC = 1: 1: 1 , wherein the concentration of lithium hexafluorophosphate is 1mol / L)=100:5, use collodion film to completely cover and seal the pole piece, then wind it with the positive pole piece, put it into the shell, and inject 1mol / L tri(trifluoromethyl Sulfuryl) methyllithium aqueous solution to make a 186502000mAh battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com