Low-magnetic-flux-leakage high-strength rotor punching piece for electric vehicle permanent magnet motor

A rotor punching, permanent magnet motor technology, applied in electric vehicles, motors, electric components and other directions, can solve the problems of increasing the weight of permanent magnet motors, difficult to increase output power, and high leakage rate, to enhance the strength of resistance to centrifugal force damage, improve The effect of output power and magnetic leakage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

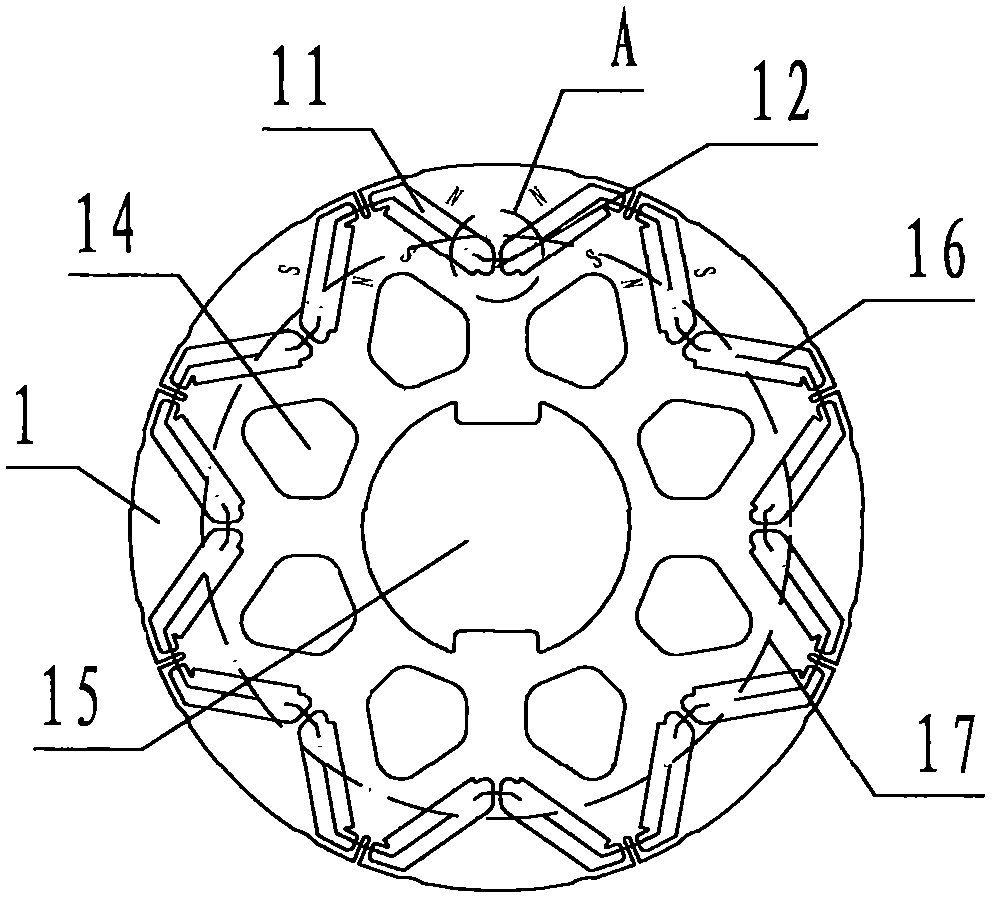

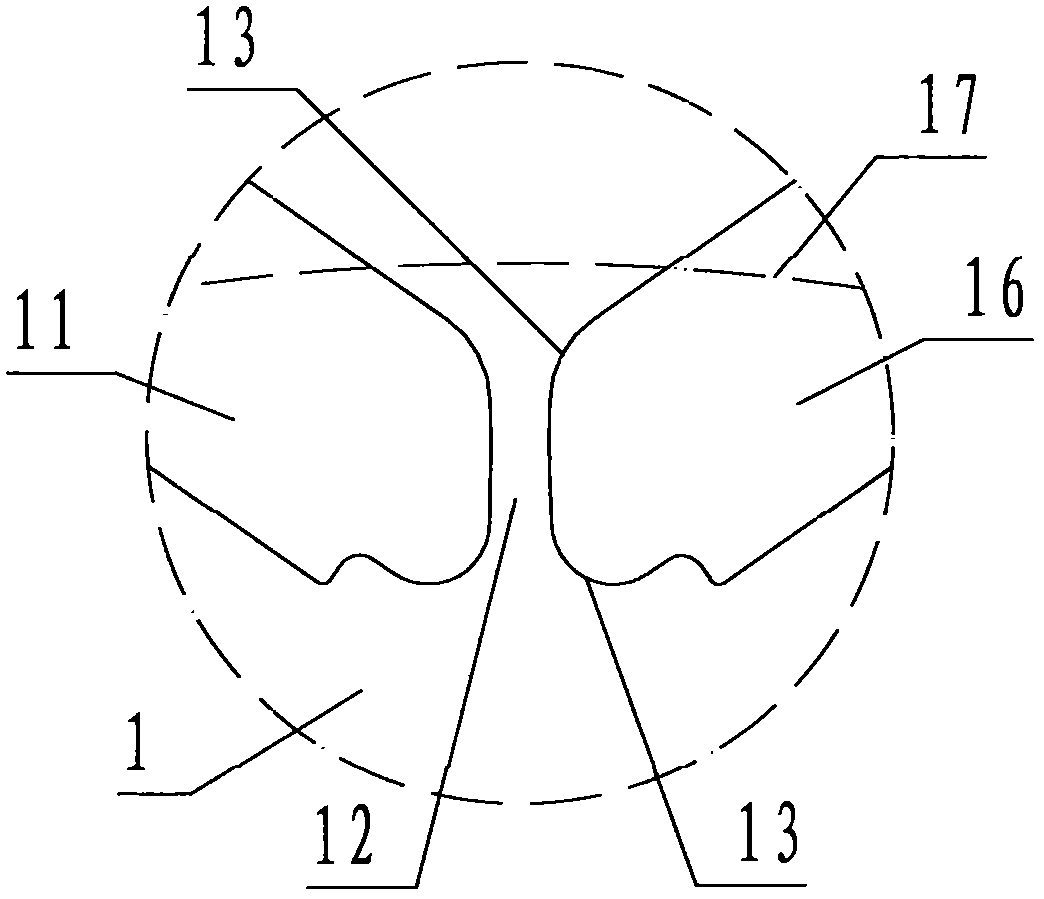

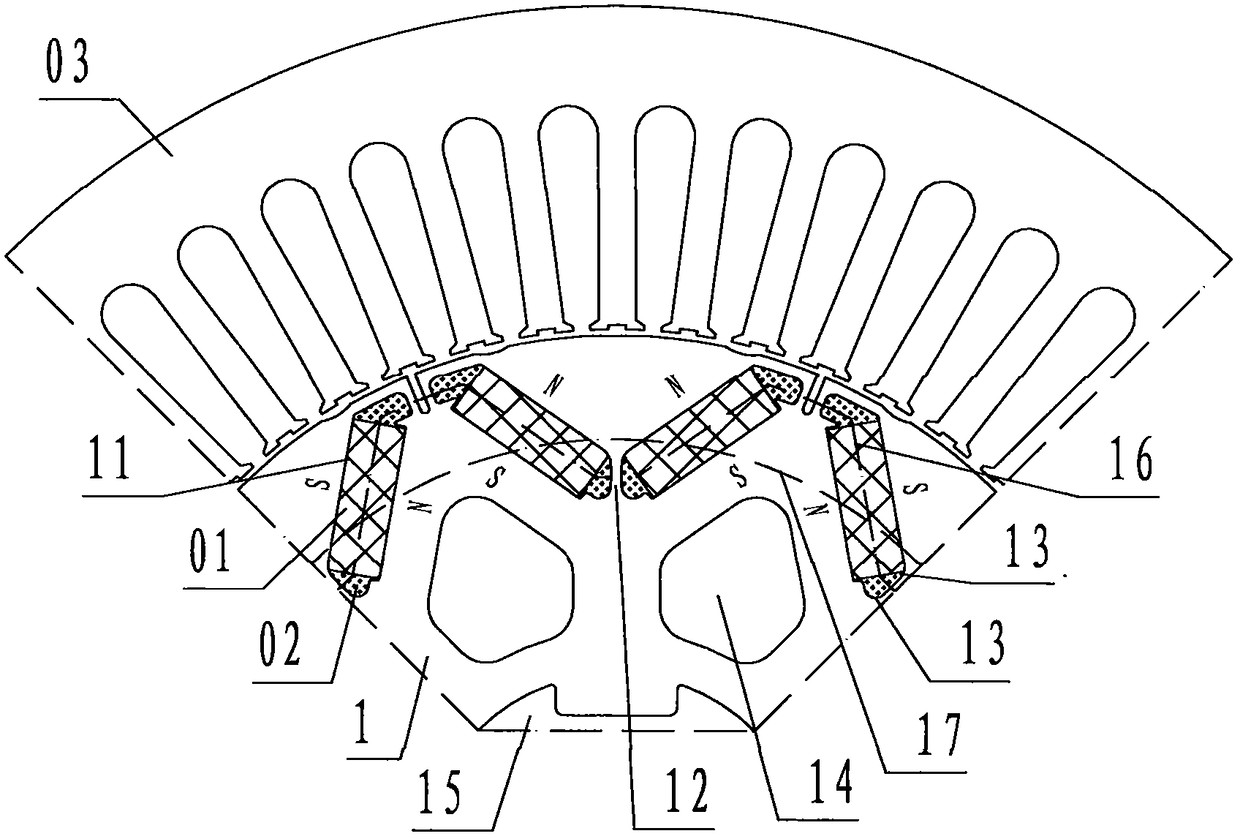

[0016] Refer to Figure 1 ~ Figure 3 , The present invention is a low-leakage and high-strength rotor punching sheet for permanent magnet motors for electric vehicles, referred to as rotor punching sheet 1. Said rotor punching sheet 1 is a round sheet-shaped alloy magnetic guide soft with an insulating paint film on the surface Magnetic components, the rotor punch 1 is provided with a magnetic steel slot 11, a connecting belt 12, a transition arc 13, a weight reduction hole 14 and a shaft hole 15. The rotor punch 1 is evenly distributed along the circumference with sixteen isolated The magnetic steel channel 11 encloses an octagonal star-shaped magnetic pole ring 16, and the magnetic steel channel 11 is a through hole for inserting the magnetic steel 01 with a rectangular cross section; based on the arrangement of the polarity of the magnetic steel 01, An imaginary concentric circle that is concentric with the rotor punch 1 is called an imaginary concentric circle 17. The imagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com