Aroma-increasing method of black tea

A technology of black tea and tea leaves, which is applied in the direction of tea treatment before extraction, etc. It can solve the problems of uneven aroma and quality of black tea, difficulty in meeting daily consumption, and flat taste of tea soup, so as to improve quality, curb the production of theabrownin, and fermentation time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

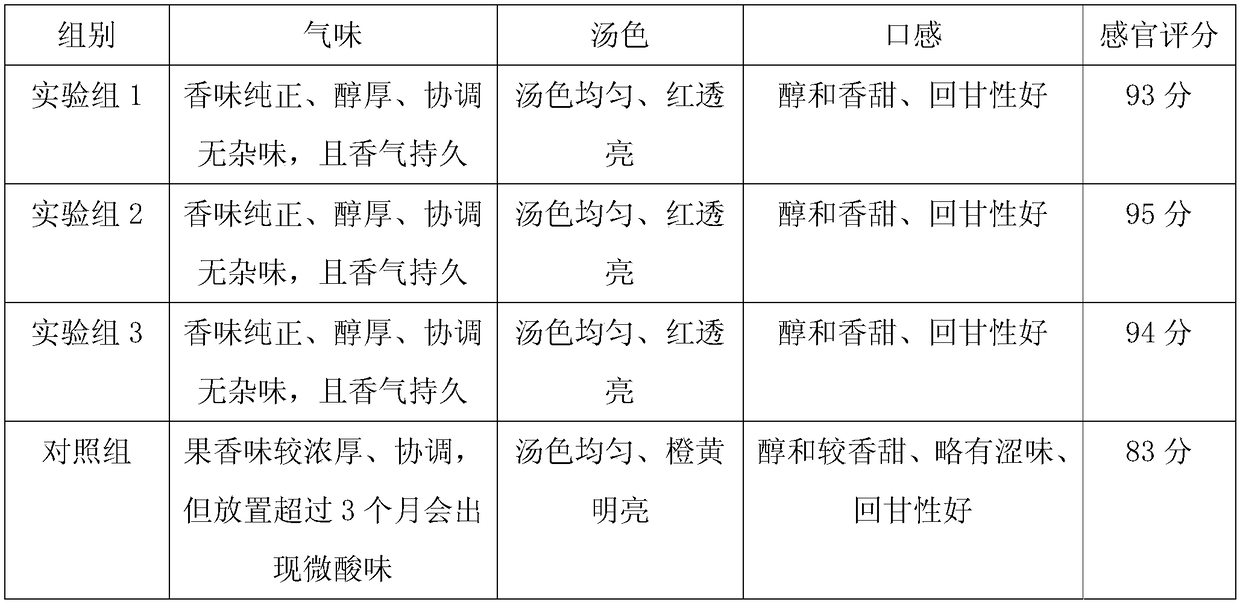

Examples

Embodiment 1

[0021] A method for enhancing aroma of black tea, comprising the following steps:

[0022] (1) Select one bud and one leaf as tea raw material, and wither and knead sequentially; spread the tea leaves obtained by kneading according to a thickness of 5 cm, and use the first red light with a wavelength of 670 nm and an illumination intensity of 250 Lx to irradiate for 30 min;

[0023] (2) Spread the tea leaves irradiated by the first red light with a thickness of 5cm in a fermentation room with a temperature of 25°C and a humidity of 65%. After 40 minutes of fermentation, use the second red light with a wavelength of 650nm and a light intensity of 180Lx Irradiate for 10 minutes, continue to ferment for 30 minutes, and then irradiate with the second red light for 5 minutes, then irradiate with ultraviolet light with a wavelength of 220 nm and an illumination intensity of 200 Lx for 5 minutes to obtain fermented tea leaves;

[0024] (3) Stack the fermented tea leaves with a thickn...

Embodiment 2

[0028] A method for enhancing aroma of black tea, comprising the following steps:

[0029] (1) Select one bud and one leaf as tea raw materials, and wither and knead in turn; spread the tea leaves obtained by kneading according to a thickness of 7 cm, and irradiate them with the first red light with a wavelength of 680 nm and an illumination intensity of 260 Lx for 35 min;

[0030] (2) Spread the tea leaves irradiated by the first red light with a thickness of 7cm in a fermentation room with a temperature of 27°C and a humidity of 70%. After 45 minutes of fermentation, use the second red light with a wavelength of 655nm and a light intensity of 190Lx Irradiate for 13 minutes, continue to ferment for 35 minutes, and then irradiate with the second red light for 8 minutes, then irradiate with ultraviolet light with a wavelength of 240 nm and an illumination intensity of 230 Lx for 8 minutes to obtain fermented tea leaves;

[0031] (3) Stack the fermented tea leaves with a thickne...

Embodiment 3

[0035] A method for enhancing aroma of black tea, comprising the following steps:

[0036] (1) Select one bud and one leaf as the tea raw material, and undergo withering and rolling in sequence; spread the tea leaves obtained by rolling according to a thickness of 8 cm, and irradiate for 40 minutes with the first red light with a wavelength of 700 nm and an illumination intensity of 270 Lx;

[0037] (2) Spread the tea leaves irradiated by the first red light with a thickness of 10cm in a fermentation room with a temperature of 28°C and a humidity of 75%. After 50 minutes of fermentation, use the second red light with a wavelength of 660nm and a light intensity of 200Lx Irradiate for 15 minutes, continue to ferment for 40 minutes, and then irradiate with the second red light for 10 minutes, then irradiate with ultraviolet light with a wavelength of 250 nm and an illumination intensity of 250 Lx for 10 minutes to obtain fermented tea leaves;

[0038] (3) Stack the fermented tea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com