Peanut and fermented soya bean chili sauce and making method thereof

A technology of chili sauce and fermented soybeans, which is applied in the field of food processing, can solve the problems of single taste, high spiciness of chili sauce, and easy to get angry, and achieve the effect of rich nutrients, strong sauce flavor, and reducing dryness and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

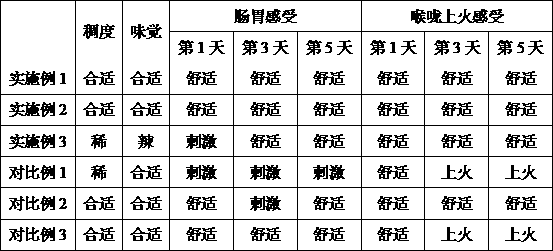

Examples

Embodiment 1

[0038] A kind of peanut bean chili sauce, comprising the following raw materials in parts by mass: 26 parts of peanuts, 15 parts of fermented soybeans, 5 parts of chili sauce, 10 parts of minced garlic, 15 parts of peanut oil, 10 parts of tea oil, 0.5 parts of star anise powder, 0.2 parts of cinnamon powder 0.3 parts of grass fruit powder, 0.5 parts of Luo Han Guo powder, 0.5 parts of licorice powder, 0.3 parts of rosemary, 3.5 parts of brown sugar, 10 parts of white wine, and 4 parts of table salt. Its method for making peanut fermented bean chili sauce comprises the following steps:

[0039] 1) After roasting the peanuts, let them dry in the air, peel and crush them;

[0040] 2) Add peanut oil and tea oil to the bottom of the pot, heat to 95°C, add minced garlic, star anise powder, cinnamon powder, grass fruit powder, Luo Han Guo powder, licorice powder and rosemary, stir well, boil for 8 minutes, and cool to room temperature;

[0041] 3) Step 2) Add the finished chili sauc...

Embodiment 2

[0044] The only difference between this embodiment and Example 1 lies in the mass parts of each component, and its preparation method is the same; a kind of peanut fermented bean chili sauce, including the following raw materials in mass parts: 30 parts of peanuts, 12 parts of fermented soybeans, and 3 parts of chili sauce , 8 parts minced garlic, 12 parts peanut oil, 15 parts tea oil, 0.2 parts star anise powder, 0.5 parts cinnamon powder, 0.6 parts grass fruit powder, 0.7 parts Luo Han Guo powder, 0.3 parts licorice powder, 0.2 parts rosemary, 3 parts brown sugar, 7 parts of white wine, 6 parts of table salt.

Embodiment 3

[0046] The only difference between this embodiment and Example 1 is the mass parts of each component, and its preparation method is the same; a kind of peanut fermented bean chili sauce, including the following raw materials in mass parts: 20 parts of peanuts, 18 parts of fermented soybeans, and 8 parts of chili sauce , 15 parts minced garlic, 18 parts peanut oil, 8 parts tea oil, 0.7 parts star anise powder, 0.2 parts cinnamon powder, 0.3 parts grass fruit powder, 0.3 parts Luo Han Guo powder, 0.7 parts licorice powder, 0.5 parts rosemary, 6 parts brown sugar, 13 parts of white wine, 3 parts of table salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com