Sweeping device for inner wall of FRPP pipe fitting

A technology for cleaning devices and pipe fittings, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of long pipe length, inconvenient disassembly, difficult cleaning, etc., and achieve simplified structure and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

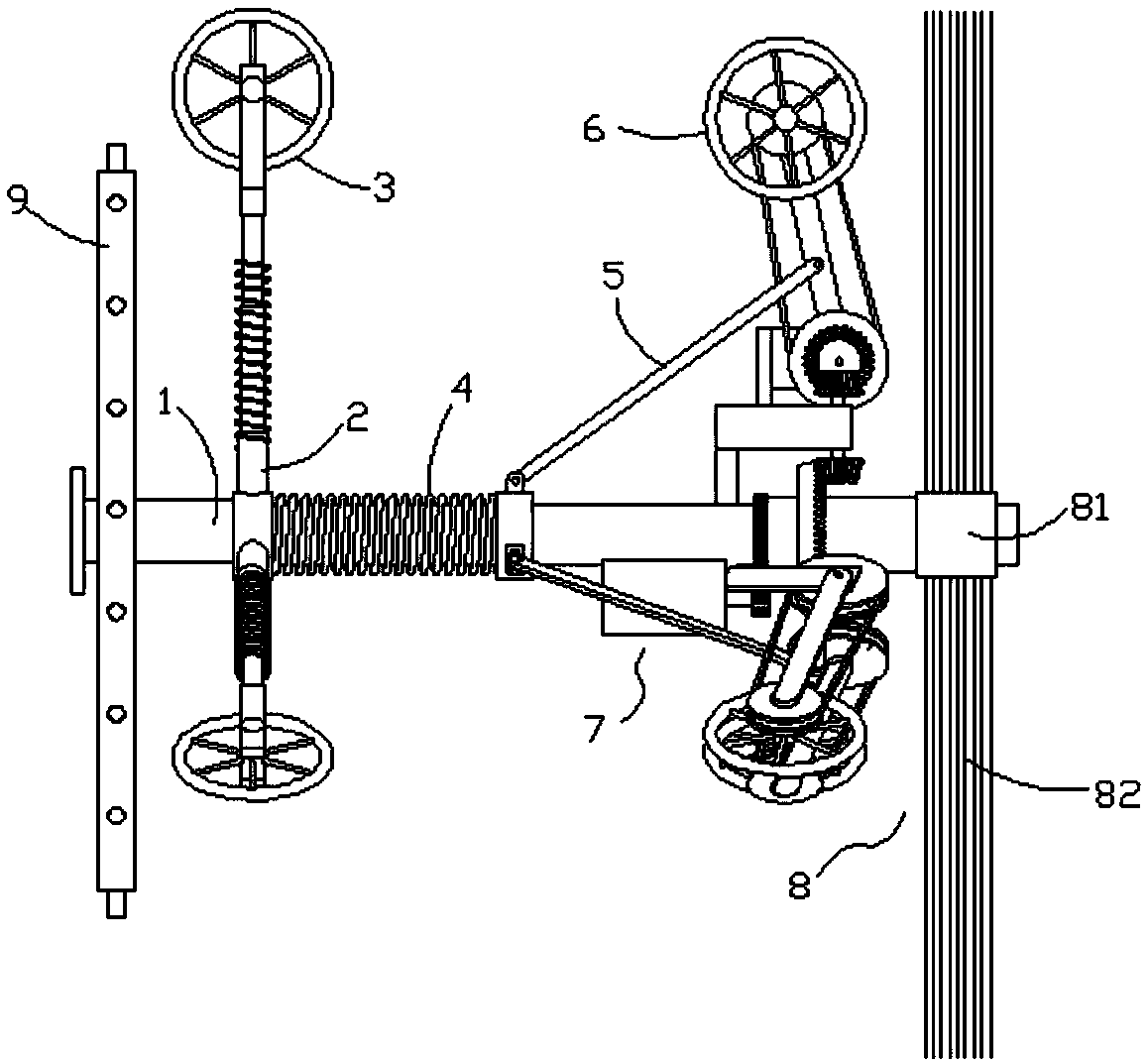

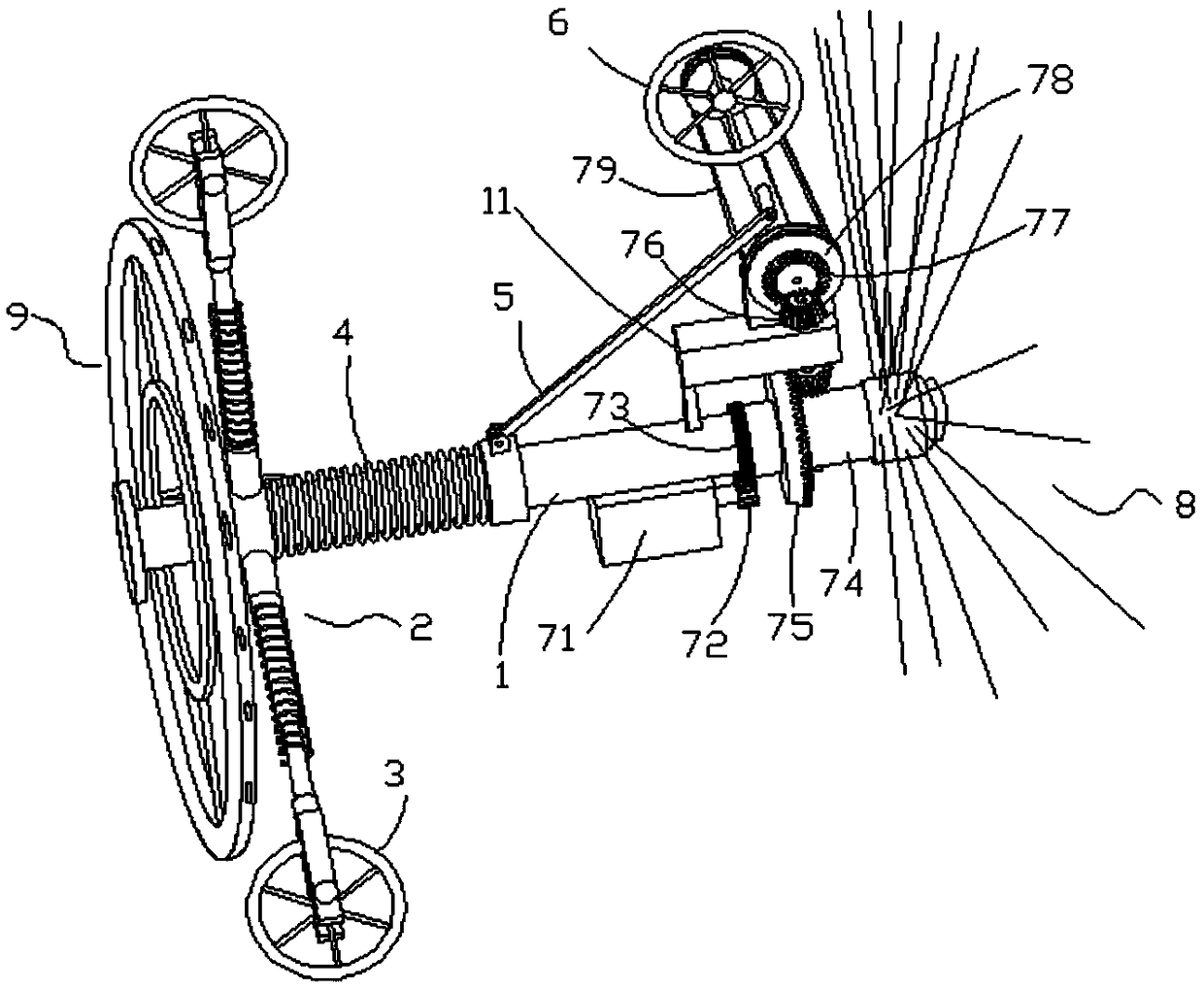

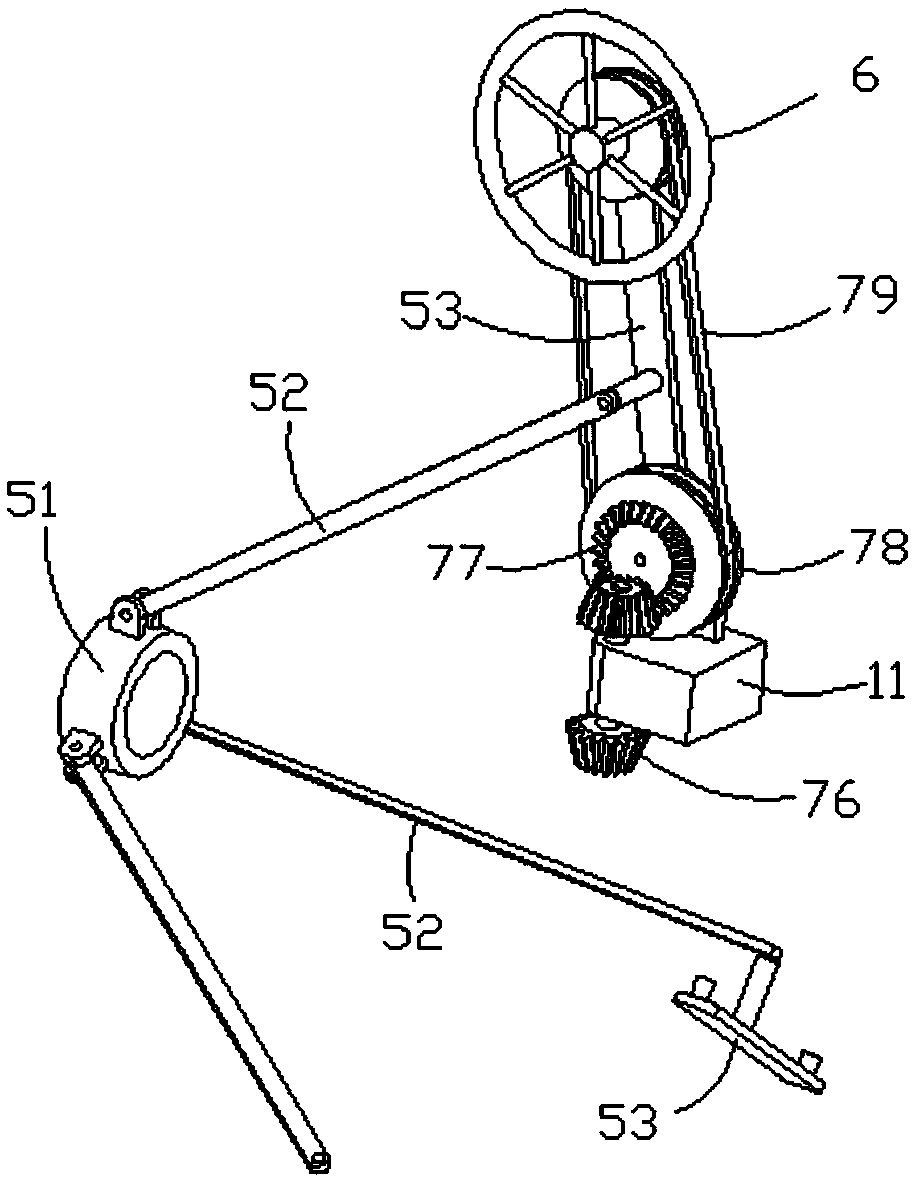

[0024] Such as Figure 1 to Figure 5 , a cleaning device for the inner wall of FRPP pipe fittings according to the present invention, including a base shaft 1, a roller frame 2, a roller 3, a first spring 4, a traveling frame 5, a traveling wheel 6, a driving mechanism 7, a cleaning brush 8 and a spraying system 9. The roller frame 2 is fixed on the base shaft 1, the three rollers 3 are elastically supported on the roller frame 2, the first spring 4 and the walking frame 5 are both sleeved on the base shaft 1, and the walking frame 5 holds the first spring 4 conflicts on the roller frame 2. The three walking wheels 6 are all rotatably connected to the walking frame 5, the cleaning brush 8 is rotatably connected to the base shaft 1, the driving mechanism 7 is fixed on the base shaft 1, and the driving mechanism 7 simultaneously drives the cleaning brush 8 and the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com