Spiral pipe winding device, control system and control method

A technology of a control system and a rotating device, applied in the field of winding pipes, can solve the problems of difficulty in meeting the needs of large-scale production, uneven personnel skill levels, and difficulty in grasping benchmarks, and achieves the effect of saving labor, reducing labor intensity and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

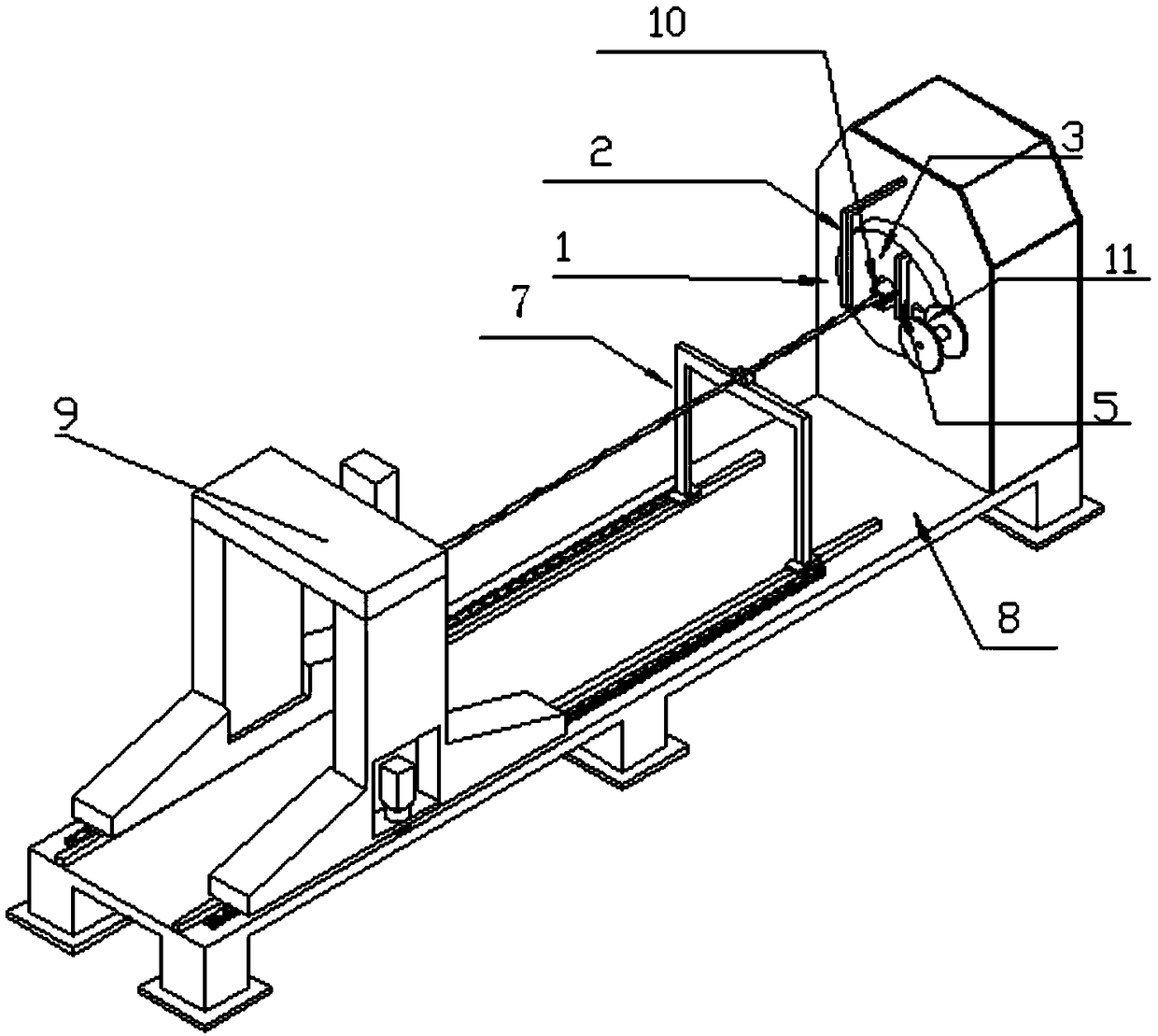

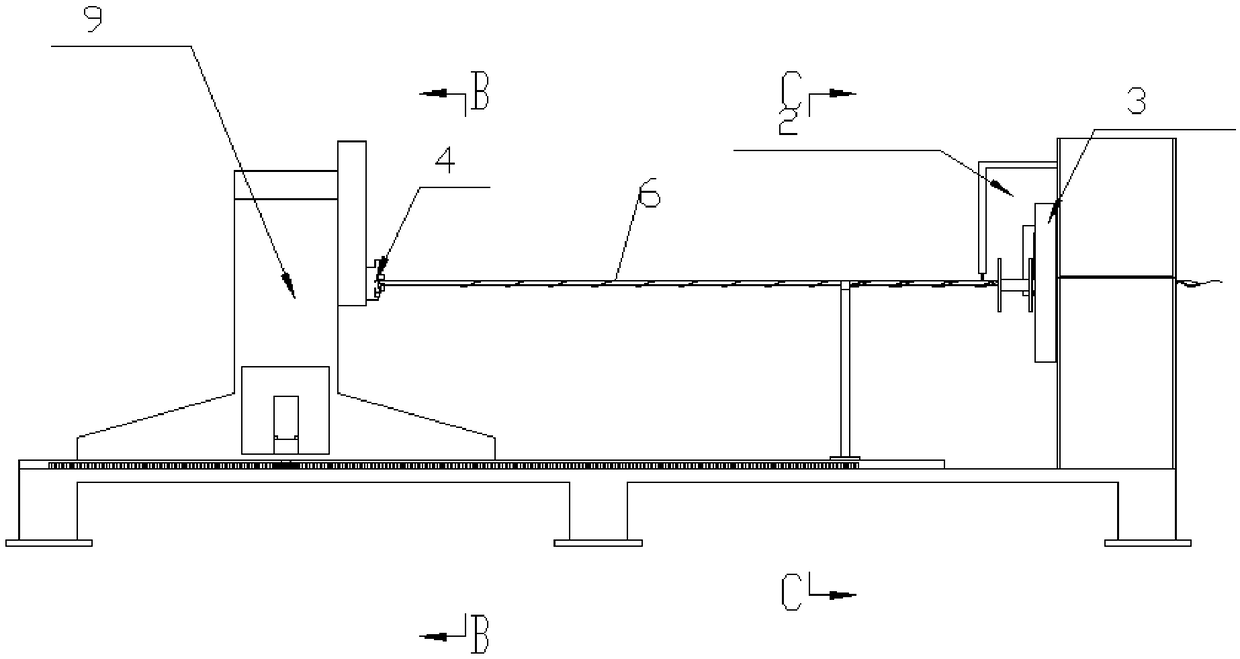

[0039] In a typical implementation of the present application, such as figure 1 As shown, the spiral coiling device includes a first support, a second support and an automatic spotting device 2,

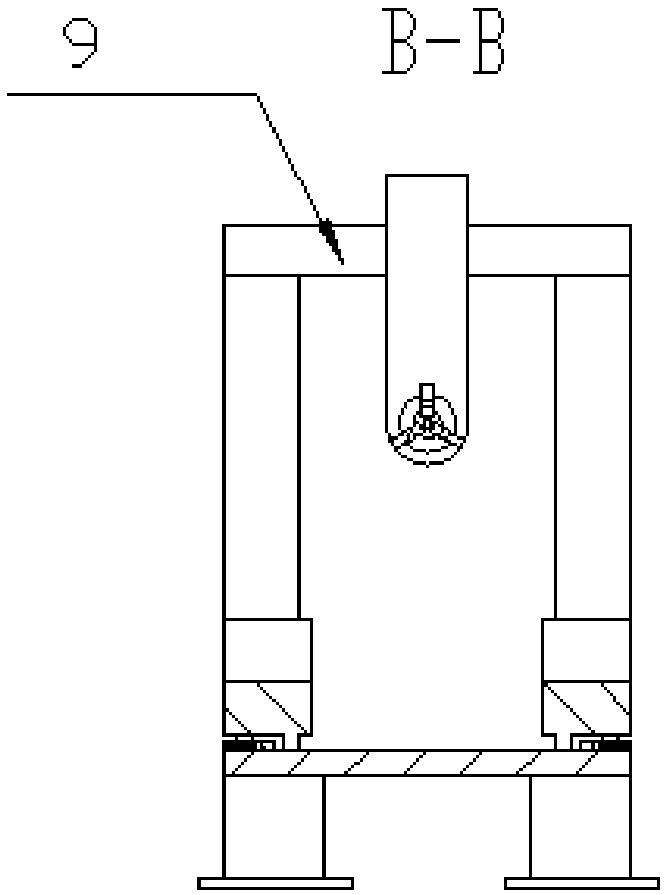

[0040] Wherein, a workpiece clamping device is provided on the first support member; a rotating device 3 is provided on the second support member 1, and a winding frame 11 is installed on the rotating device 3. When the winding member is a wire, The winding frame 11 can be designed as a wire wheel. The first support member 9 and the second support member 1 are all arranged on the base 8, the second support member 1 is fixed, and the first support member 1 moves back and forth along the guide rail on the base 8; on the second support 1.

[0041] These parts that this device comprises also can be set independently respectively, for example rotating device is arranged on the ground, and walking device is separately arranged on a base, moves back and forth along the base.

[0042] The...

Embodiment approach

[0059] The specific implementation is as follows:

[0060] 1. First locate the starting point, and use the distance detection tool to determine the starting point of the pipe fitting.

[0061] 2. Set the parameters of the PC.

[0062] 3. Clamp the pipe fittings.

[0063] 4. Send the wire into the wire drawing mechanism, and use the point-fixing system to point-fix the starting point.

[0064] 5. Start winding and point solid.

[0065] 6. After the winding is completed, each part is reset to prepare for the next workpiece; it can also be reset after winding to carry out the next round of winding.

Embodiment 2

[0067] The bottom of the second support frame in the present invention is not fixed, and can be figure 1 The guide rail in moves, and the first support frame is fixed; The rest is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com