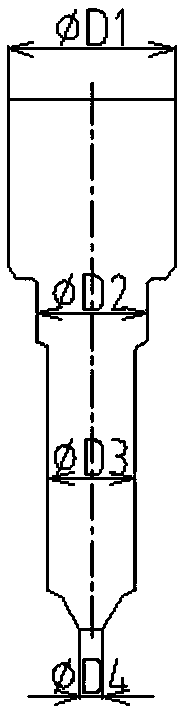

Cold extrusion forming process for nozzle needle valve body

A forming process and needle valve body technology, applied in the direction of valve devices, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult deformation, achieve the effect of complete metal streamline, easy automatic production, and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

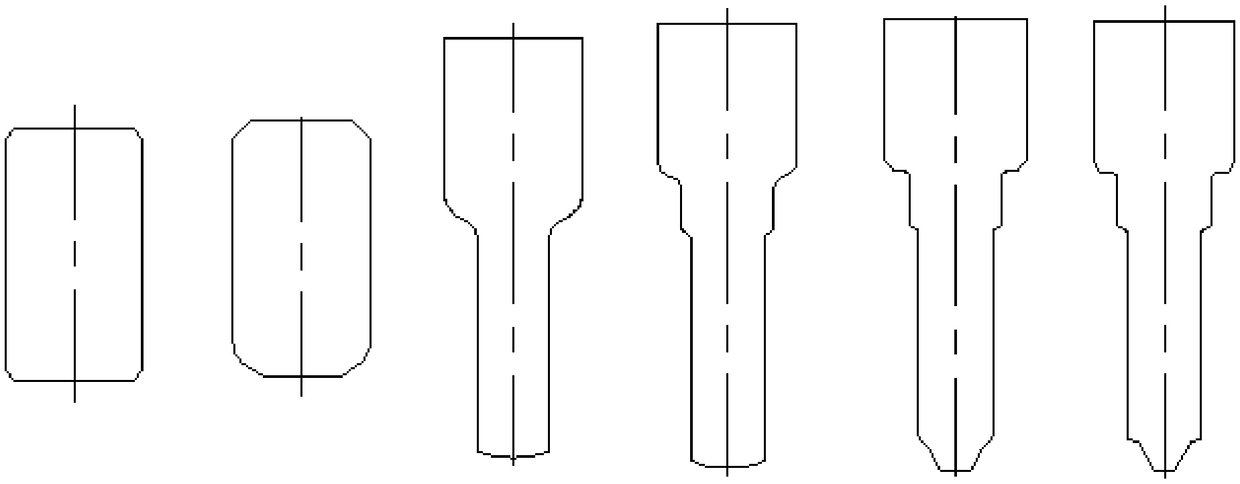

Method used

Image

Examples

Embodiment

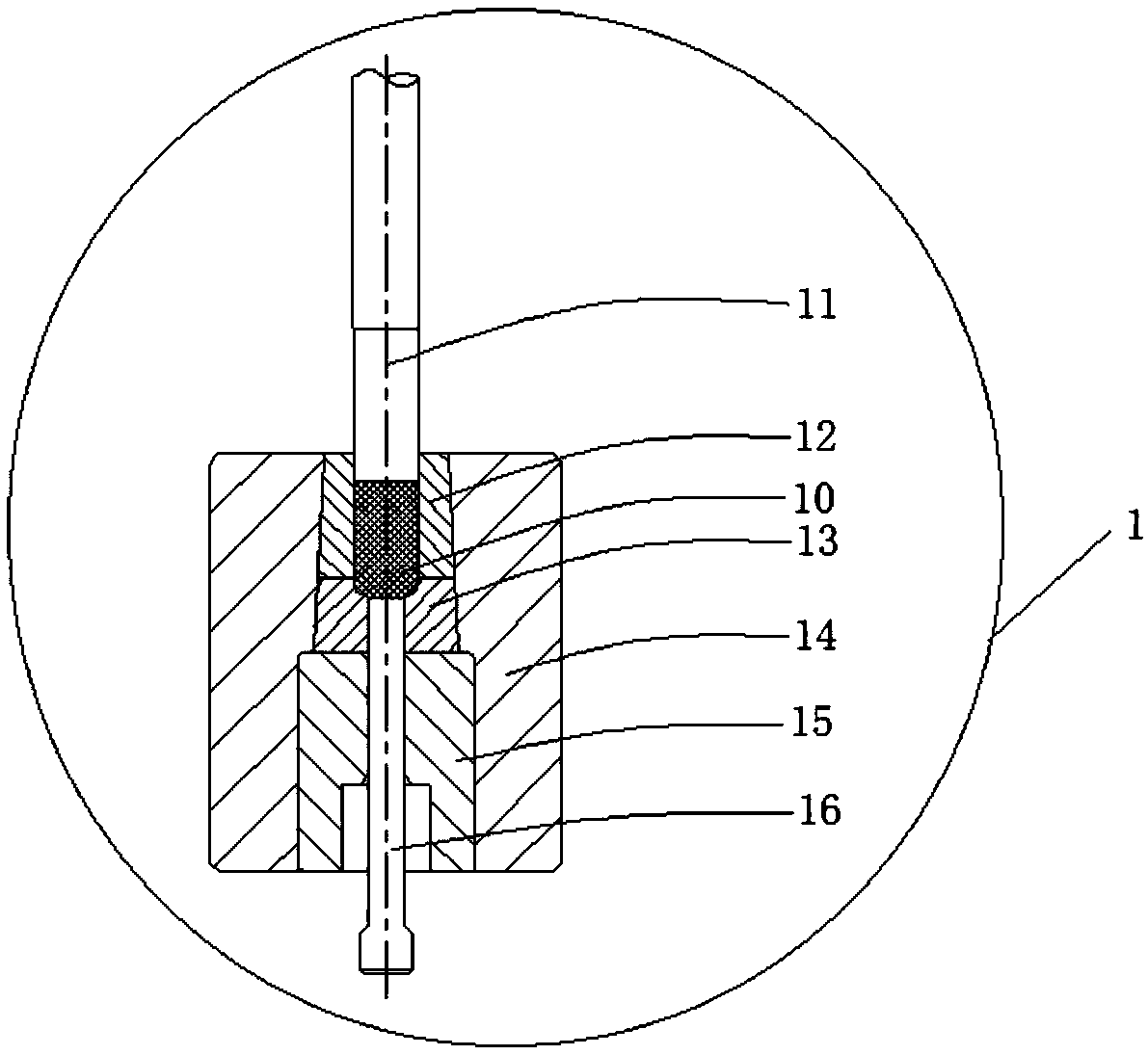

[0053] Using a circular saw to cut the blank to obtain the blank 10, then chamfering the two ends of the blank 10, and subjecting the blank 10 to annealing, shot blasting and lubrication;

[0054] (a) cold finishing

[0055] Use a circular saw to saw the blank and cut it to get the blank, and then pretreat the blank, the pretreatment is to chamfer the two ends of the blank, and anneal, shot blast and lubricate the blank ;

[0056] The pretreated blank 10 is placed in the cavity formed by the first core A12 and the second core A13, the punch A11 is located on one side of the blank 10, and the ejector pin A16 is located on the other side of the blank 10 and is connected with the The blanks are offset, and the punch A11 moves toward the blank along with the slider of the pressure forming machine, so that the two ends of the blank 10 are forged and flattened. After the forging is completed, the blank 10 is ejected through the ejector rod A16;

[0057] (b) Positive extrusion rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com