A rope-driven serpentine pulse laser processing robot

A technology of snake-like robots and pulsed lasers, applied in laser welding equipment, metal processing equipment, manipulators, etc., can solve problems such as the difficulty of scanning galvanometers, and achieve the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] The rope-driven snake-shaped robot provided by the present invention has the characteristics of a slender structure, and can guide pulsed laser light into a narrow space for operation, and the processing track of the pulsed laser light is completely under control during the whole process. The end of the rope-driven snake-like robot can move in three-dimensional space, which can realize the processing of three-dimensional contours by pulsed laser.

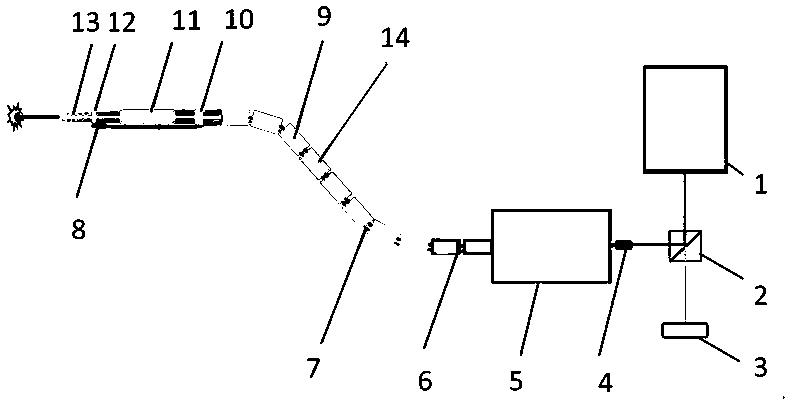

[0022] Specifically, as figure 1 The shown rope-driven serpentine pulse laser processing robot of the present invention at least includes the following parts:

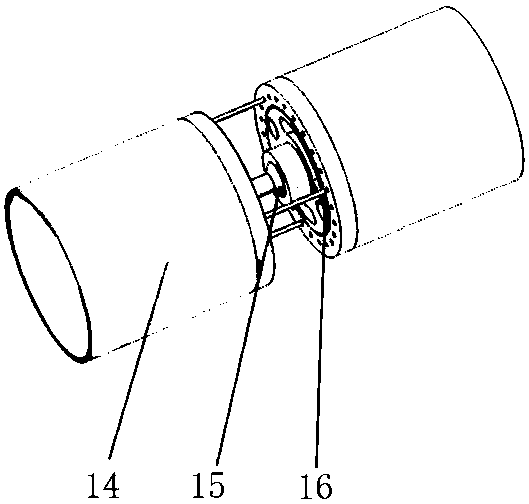

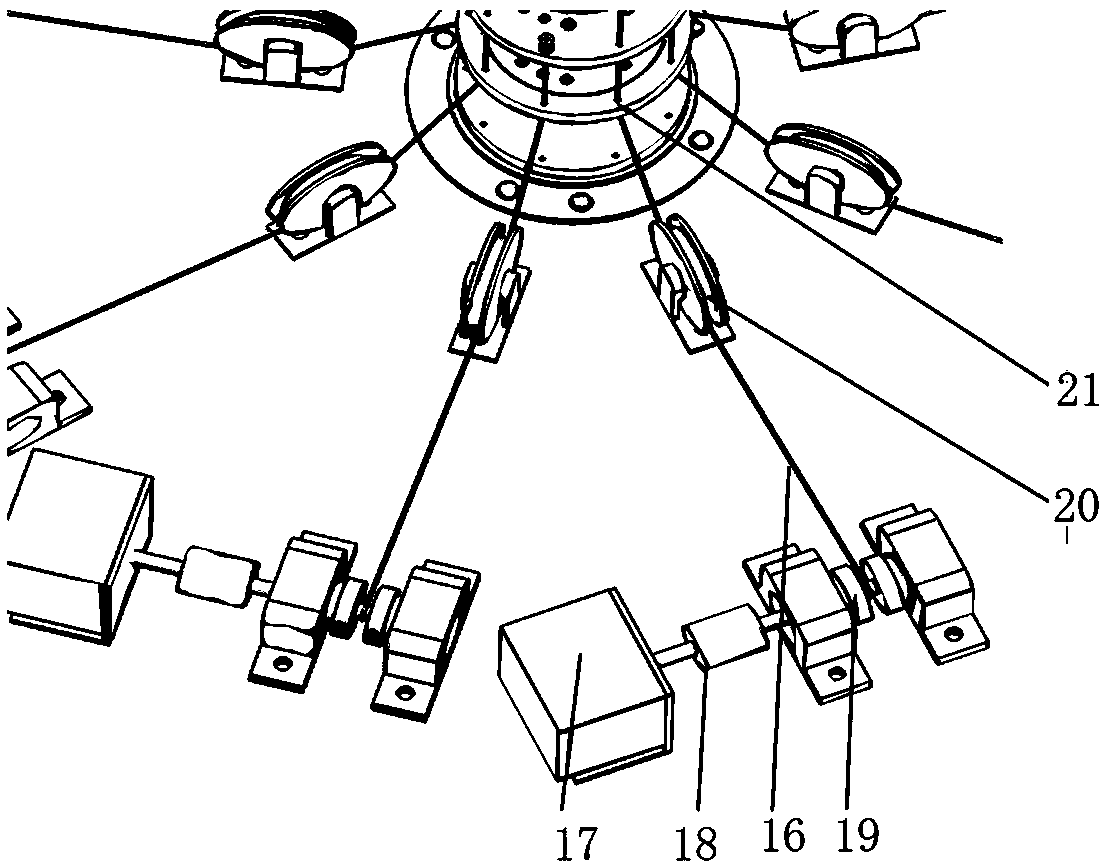

[0023] A snake-shaped robot 9, the snake-shaped robot 9 is composed of at least two joints 14, and the joints 14 are connected by universal ball joints. The motor 17 is used to drive the reel 19 to rotate through the coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com