Wood cutting machine that collects sawdust and cuts isometrically

A technology of equidistant cutting and cutting machine, which is applied in the direction of wood processing appliances, special forming/shaping machines, forming/shaping machines, etc., which can solve problems such as excess material, mechanical operation influence, wood waste, etc., to improve the range and avoid The effect of wood waste and reduction of residual materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

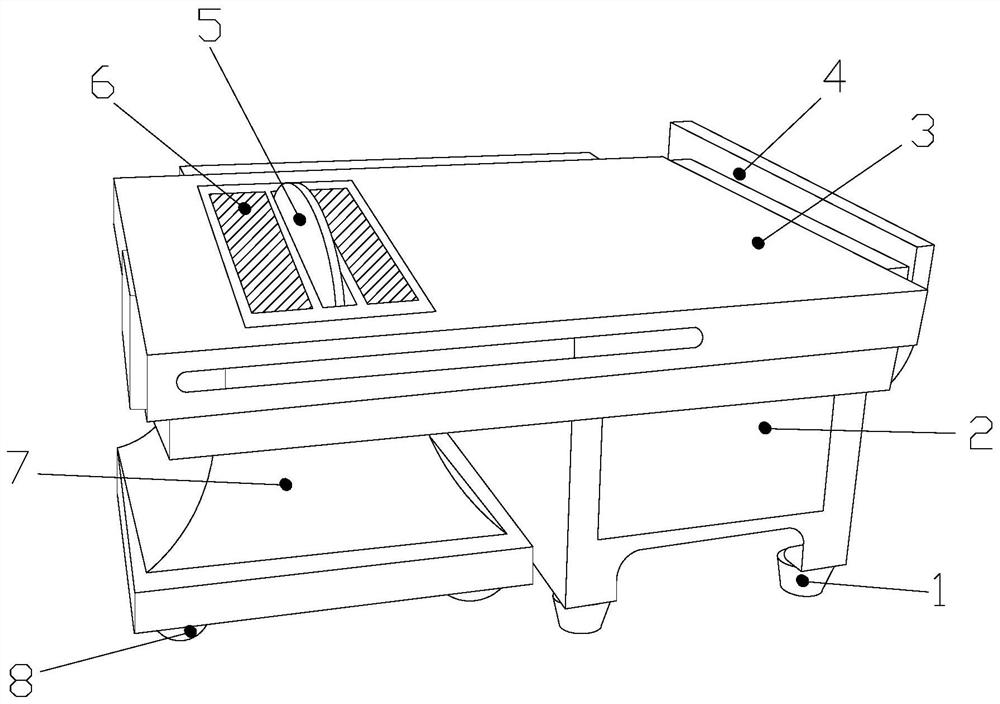

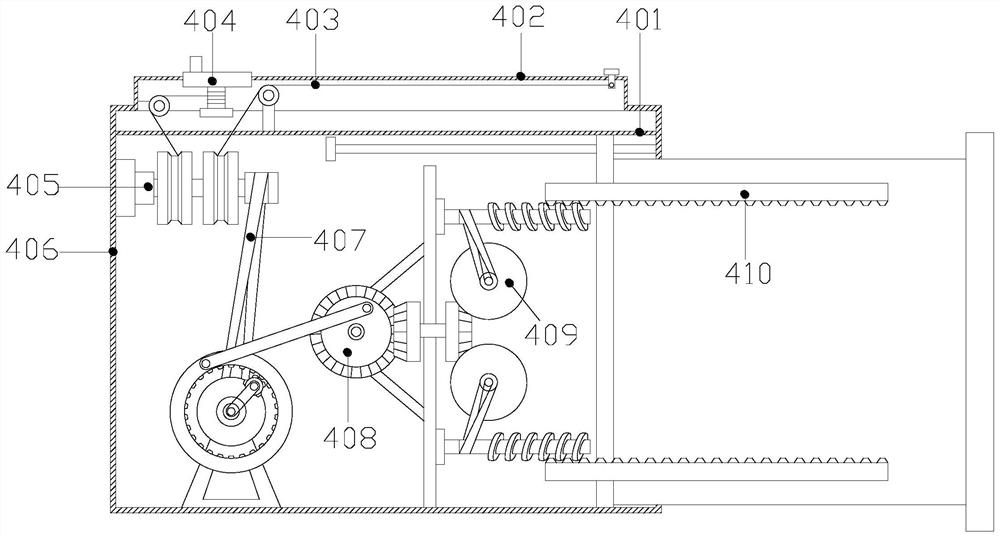

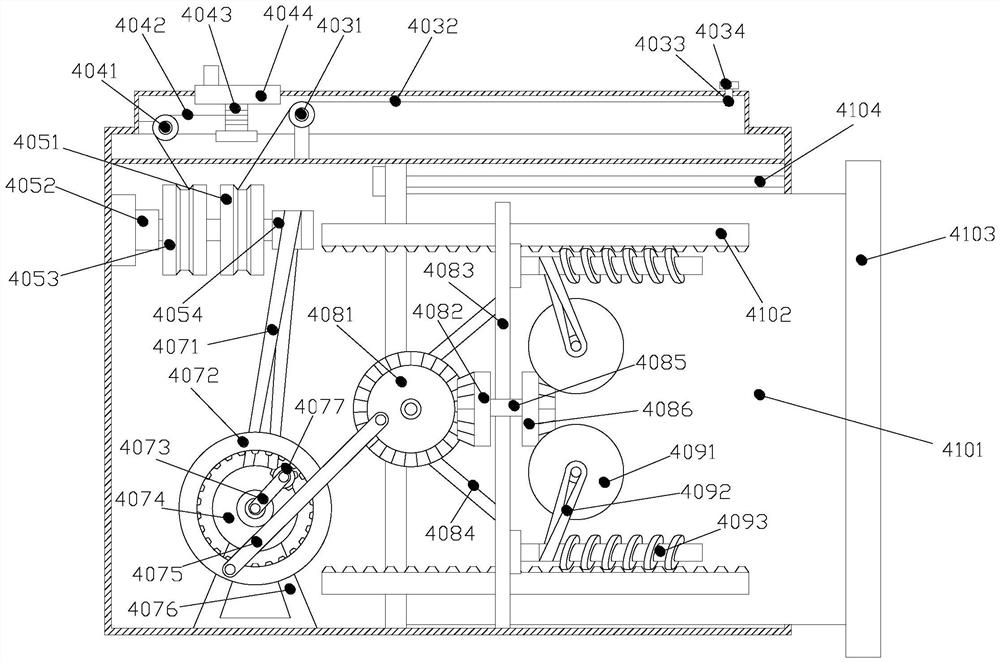

[0021] see Figure 1-Figure 3, the present invention provides a wood cutting machine capable of collecting sawdust and cutting equidistantly. There are four moving wheels 8, four of which are mounted on the four corners of the bottom of the cutting host 7 by fastening, and four of the fixed feet 1 are installed on the four corners of the bottom of the control host 2 by embedding. The tops of the control host 2 and the cutting host 7 are fitted with the two ends of the bottom of the processing table 3 respectively, the left end of the surface of the processing table 3 is provided with a dust-absorbing net 6, and the cutting sheet 5 is arranged in the middle of the dust-absorbing net 6 and the bottom Connected with the cutting main machine 7, the telescopic device 4 is installed on the right end of the processing table 3 by buckling, and the telescopic device 4 includes a partition plate 401, a chute 402, a main transmission mechanism 403, a reset mechanism 404, a second transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com