Waterproof sound insulation building plate

A technology of building boards and sound insulation layers, applied in the direction of buildings, building components, building structures, etc., can solve the problems that the construction site is easy to cause pollution, affect the normal life of the residence, and the wall boards have no sound insulation and fire prevention, etc., to achieve enhanced strength, increased Effect of area, effect to raise soundproofing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

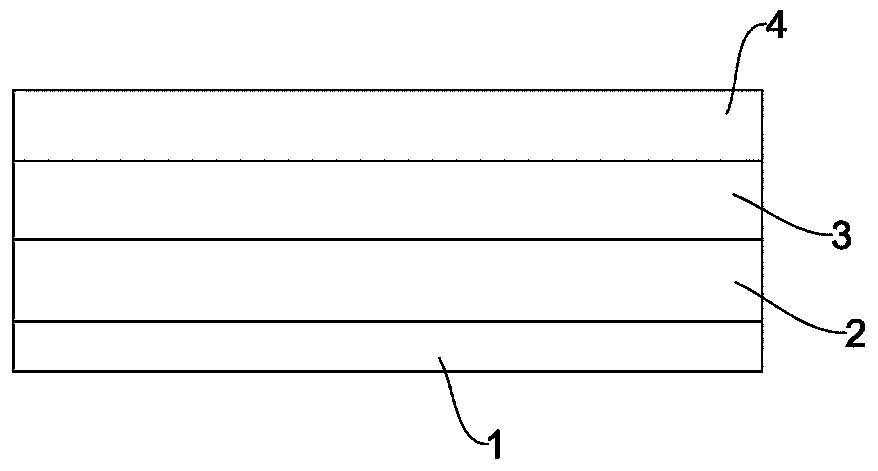

[0031] like Figures 1 to 4 A waterproof and sound-insulating building board shown in and 7 includes a substrate layer 1 , a first sound-insulating layer 2 , a second sound-insulating layer 3 and a panel layer 4 from inside to outside.

[0032] The panel layer 4 includes a PVC waterproof layer 41 and a ceramic plate layer 42 arranged on the inside of the PVC waterproof layer 41. The upper surface of the PVC waterproof layer 41 has a plurality of drainage grooves 411. The setting of the drainage grooves can speed up drainage and Increase the area of the PVC waterproof layer, which can reduce the impact of rainwater on the waterproof and sound-proof building board, ensure the stability of the building board and increase its service life. The surface of the drainage groove 411 is provided with a plurality of reinforcing ribs 4111, The reinforcing ribs can not only further increase the area of the PVC waterproof layer, but also further improve the stability of the building boa...

Embodiment 2

[0039] like figure 1 , 3 , 5, 6, and 7 show a waterproof and sound-insulating building board, which sequentially includes a substrate layer 1, a first sound-insulating layer 2, a second sound-insulating layer 3 and a panel layer 4 from inside to outside. The difference from Example 1 is:

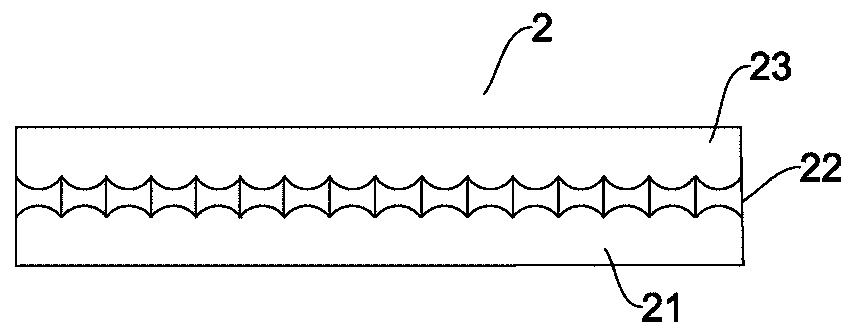

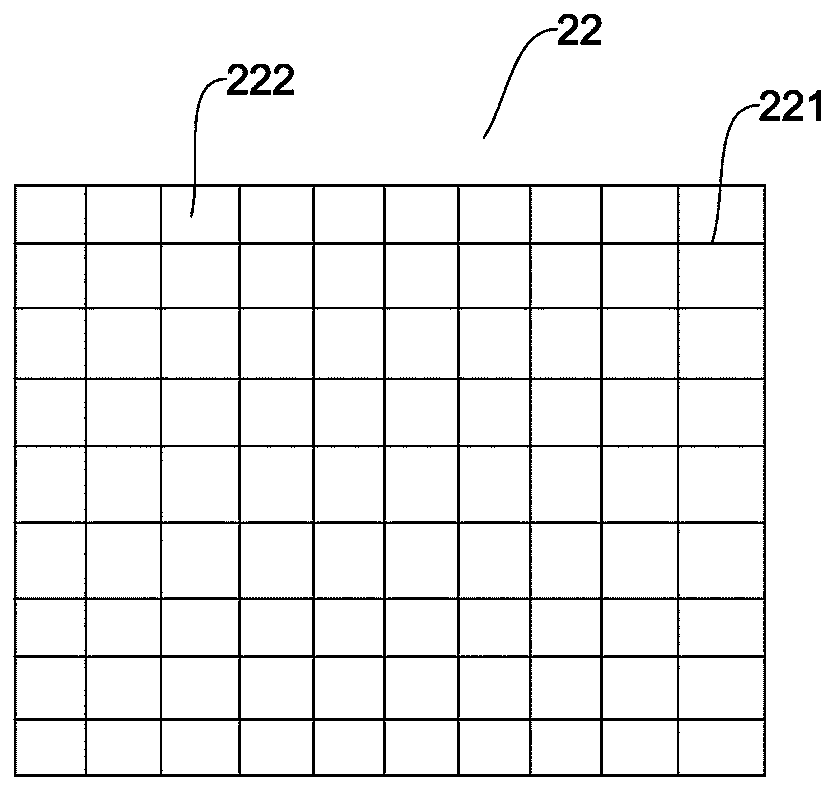

[0040] The sides of the first sound-insulating cotton layer 21 and the second sound-insulating cotton layer 23 close to the glass fiber mesh layer 22 form a plurality of protrusions 5 toward the glass fiber mesh layer 22, and the protrusions 5 can be inserted into corresponding hollow parts. 222. On the one hand, the protrusions are placed in the hollowed out parts and fit together, which can strengthen the strength of the glass fiber mesh cloth layer to a certain extent, and improve the strength of the first sound insulation cotton layer; In the case of affecting the sound insulation quality of the sound insulation cotton, the volume of the sound insulation cotton can be increased to the...

Embodiment 3

[0045] like figure 1 , 3 1. A waterproof and sound-insulating building board shown in 5 to 7 includes a substrate layer 1 , a first sound-insulating layer 2 , a second sound-insulating layer 3 and a panel layer 4 from inside to outside. The difference from Example 2 is:

[0046] The hollow part 222 is provided with sound-insulating filling particles. When producing the first sound insulation layer, first cover the glass fiber mesh cloth layer on the first sound insulation cotton layer or the second sound insulation cotton layer, and then fill the hollow part with some porous sound insulation filling particles, such as ceramics and bentonite, and then cover Another layer of sound-proof cotton is pressed to form the first sound-proof layer. This operation can further improve the effect of sound insulation, and also improve the thermal insulation effect of the glass fiber mesh cloth layer.

[0047] A 3M glue layer is provided between the first sound insulation layer 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com