Method of preparing glass-ceramic with nepheline tailings being main raw material

A main raw material, a technology of glass-ceramics, applied in the field of preparation of glass-ceramics, can solve the problem of single utilization of nepheline tailings, etc., and achieve the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

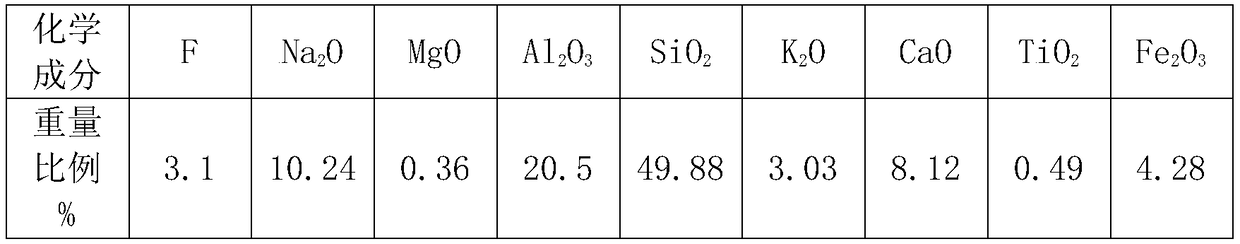

Method used

Image

Examples

Embodiment 1

[0040] 1. Accurately weigh the following raw materials and send them to the mixer for mixing (mixing time is 4 minutes, add 26Kg of water).

[0041] raw material name

Sodium fluorosilicate

Nepheline tailings

Quartz sand

heavy calcium

Weight (kg)

25.2

433.5

10.2

57.9

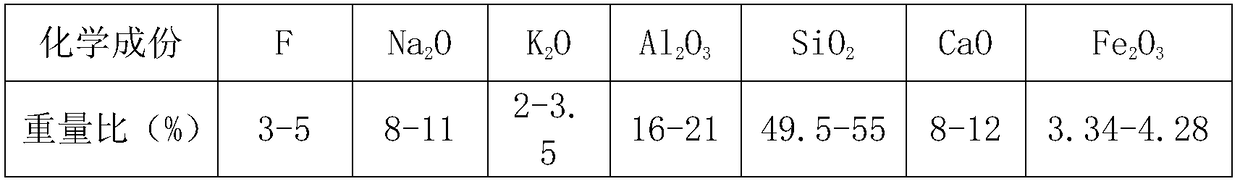

[0042] Wherein, the main component weight percentage content of various raw materials is shown in the following table:

[0043] chemical composition

Sodium fluorosilicate

Nepheline tailings

Quartz sand

heavy calcium

F

59.43

0.00

0.00

0.00

Al 2 o 3

0.00

23.65

0.00

0.00

SiO 2

31.28

53.38

99.12

0.00

CaO

0.00

1.91

0.00

54.77

[0044] 2. Send the above-mentioned mixture into the all-electric melting furnace for melting. The melting temperature is 1550°C. After clarification and homogenization, the melted glass enters the material channel through the liquid flow...

Embodiment 2

[0048] 1. Accurately weigh the following raw materials and send them to the mixer for mixing (mixing time is 4 minutes, add water 17Kg.).

[0049] raw material name

Sodium fluorosilicate

Nepheline tailings

Quartz sand

heavy calcium

Weight (kg)

25.2

338.4

82.9

97.8

[0050] 2. Send the above-mentioned mixture into the all-electric melting furnace for melting. The melting temperature is 1500°C. After clarification and homogenization, the melted glass enters the material channel through the liquid flow hole and the ascending channel, and the temperature drops to 1300°C, and then enters the calendering process. The working pool enters the annealing kiln after being calendered and formed by a calender (forming temperature 1050°C).

[0051] 3. Anneal the rolled glass plate annealing kiln. The temperature of entering the kiln is 650°C. After holding at 650°C for 15 minutes, cool down to 580°C at a rate of 3°C / min, and then cool down to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com