Hydrophobic-superoleophylic sponge as well as preparation method and application thereof

A super-oleophilic and sponge technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problem of loss of hydrophobic and lipophilic properties on the surface of materials, affecting selectivity and reusability, and complicated operation of the modification process and other problems, to achieve the effect of excellent separation ability, convenient large-scale production, and short experimental cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of hydrophobic-super lipophilic sponge of the present invention, comprises the following steps:

[0035] (1) Pretreatment of the sponge: wash the melamine sponge with 75%-100% ethanol and water repeatedly for 3 times, then place it in an oven at 50-80°C, and dry it for 12-24 hours.

[0036] (2) Modification of kaolin: add 0.15-0.3g of perfluorooctanoic acid (PFOA) and 0.015-0.03g of sodium hydroxide into 3-6mL of ethanol and stir until dissolved, then add 1.5-3g of kaolin (chemically pure), ultrasonic for 10-20min , the mixed solution was transferred to a round-bottomed flask, placed in a preheated water bath (52°C), and subsequently, 0.05-0.1mL diethoxydimethylsilane (DEDMS) was added to the mixed solution, stirred, and reacted After 0.5-1 hour, the obtained product solution is dried in an oven at 50-80° C. for 1-2 hours to obtain modified kaolin powder.

[0037] (3) Preparation of silanized modified kaolin suspension: take the modified ka...

Embodiment 1

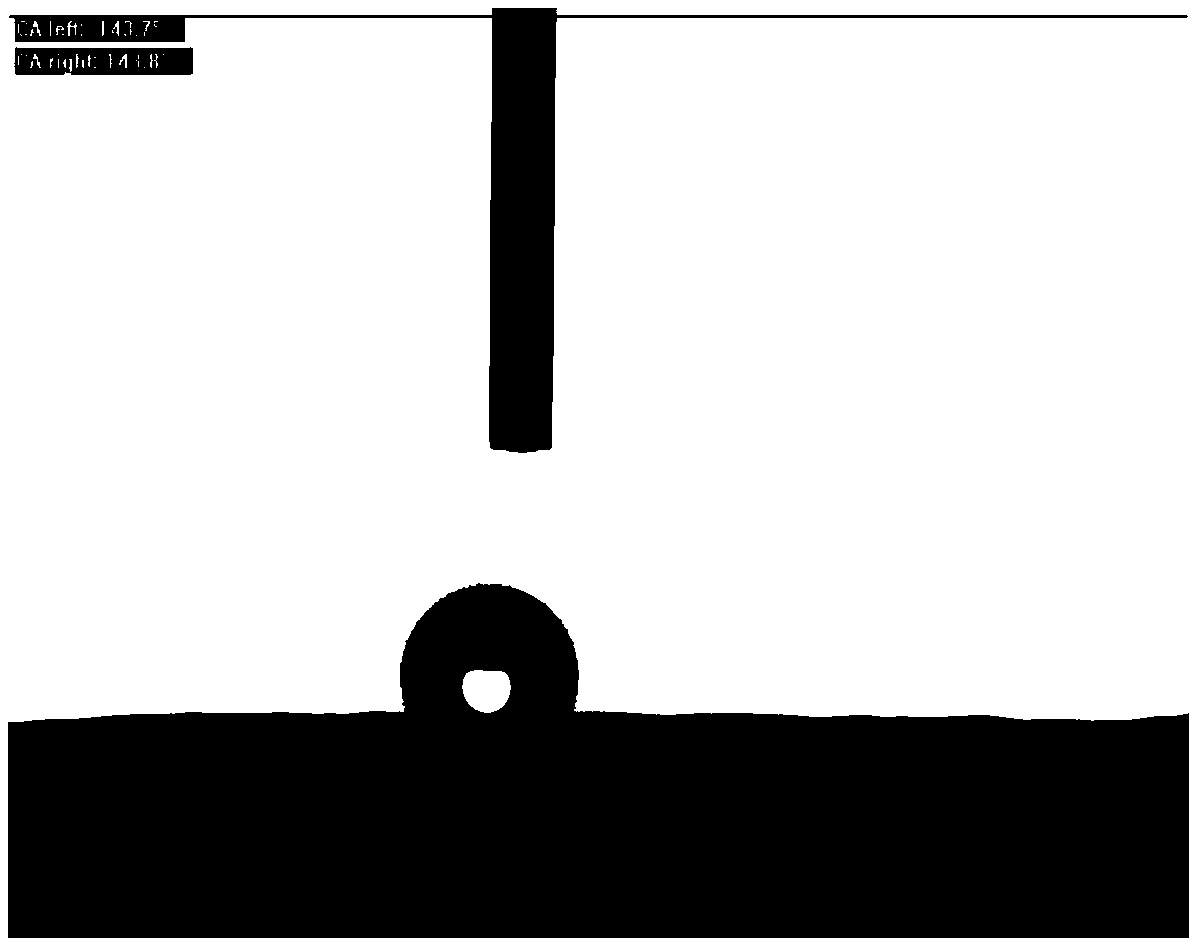

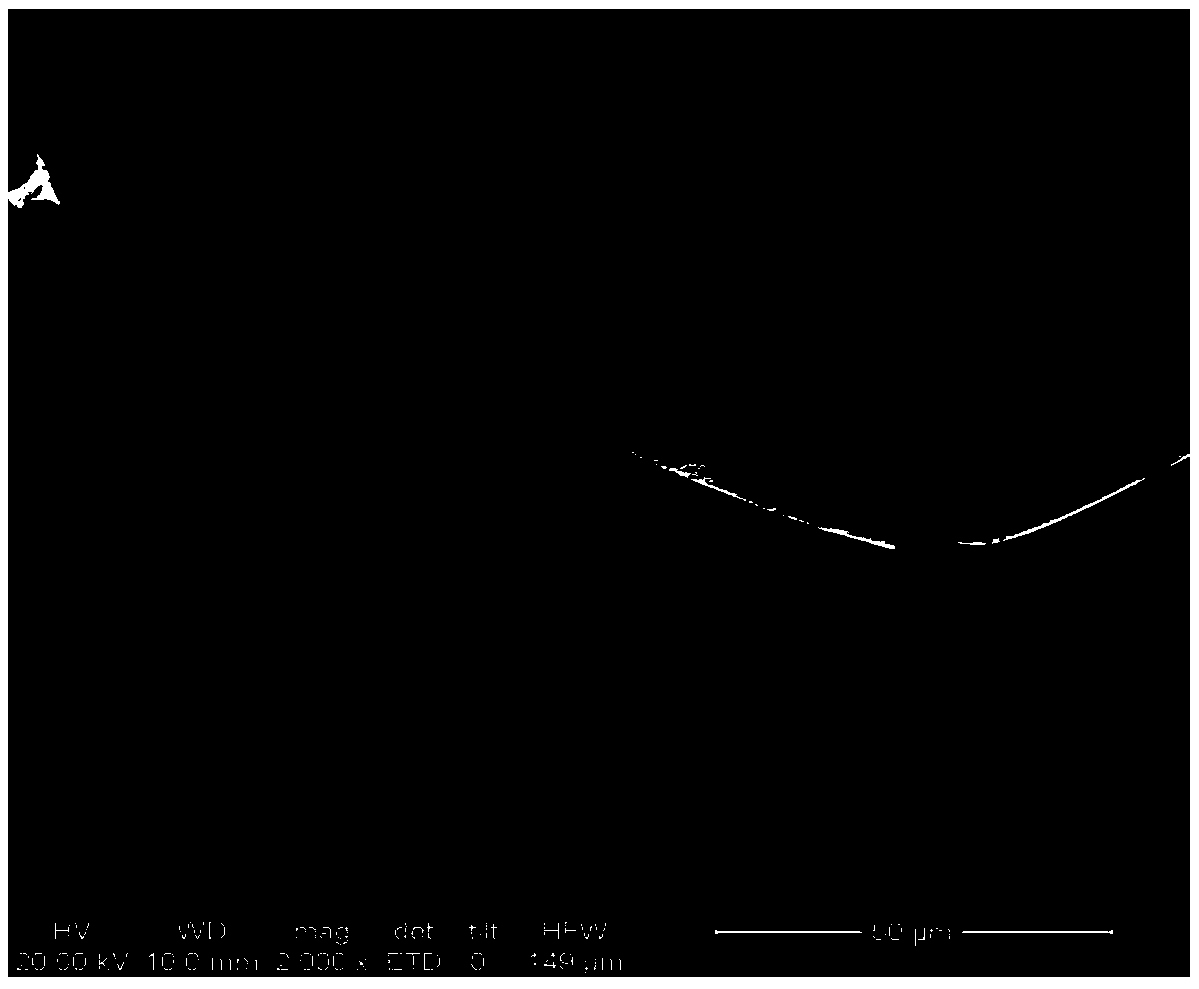

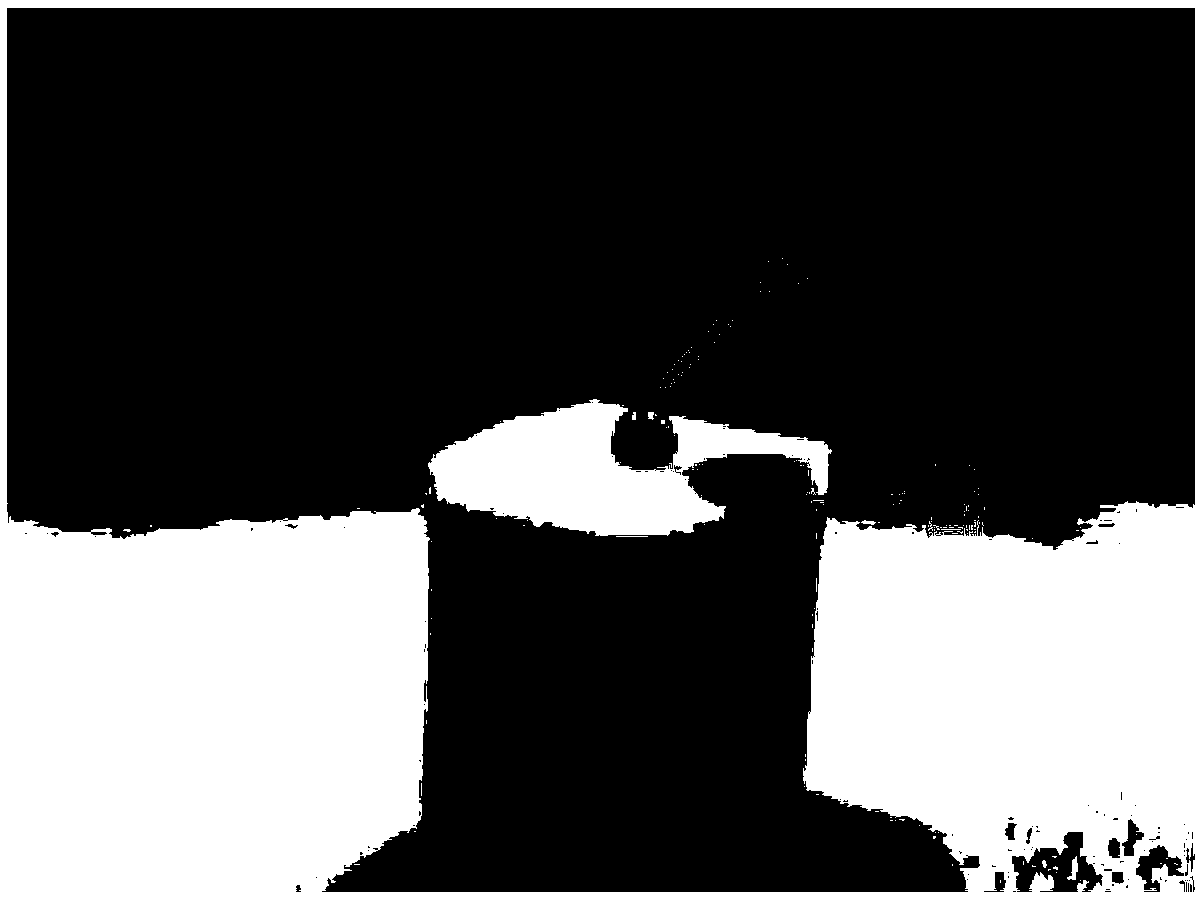

[0041] A kind of hydrophobic-super-oleophilic sponge of the present invention, this hydrophobic-super-oleophilic sponge is mainly prepared by using melamine sponge as a carrier and loading modified kaolin in the melamine sponge, and the modified kaolin mainly adopts solvent volatilization method, by Modified perfluorooctanoic acid (PFOA).

[0042] A kind of preparation method of the hydrophobic-super lipophilic sponge of above-mentioned present implementation, comprises the following steps:

[0043] (1) Pretreatment of the sponge: firstly, a 2cm×2cm×2cm melamine sponge was repeatedly washed three times with 100% ethanol and water, placed in an oven at 50° C., and dried for 24 hours.

[0044] (2) Modification of kaolin: Add 0.15g of perfluorooctanoic acid (PFOA) and 0.015g of sodium hydroxide into 3.6mL of ethanol and stir until dissolved, then add 1.5g of kaolin powder Kaolin, sonicate for 20min, and transfer the mixture to a round bottom flask , placed in a preheated water b...

Embodiment 2

[0051] A kind of preparation method of hydrophobic-super lipophilic sponge of the present invention, comprises the following steps:

[0052] (1) Pretreatment of the sponge: firstly, a 2cm×2cm×2cm melamine sponge was repeatedly washed three times with 100% ethanol and water, placed in an oven at 50° C., and dried for 24 hours.

[0053] (2) Modification of kaolin: Add 0.15g of perfluorooctanoic acid (PFOA) and 0.015g of sodium hydroxide into 3.6mL of ethanol and stir until dissolved, then add 1.5g of kaolin powder Kaolin, sonicate for 20min, and transfer the mixture to a round bottom flask , placed in a preheated water bath (52°C), then, 0.05mL diethoxydimethylsilane (DEDMS) was added to the mixture, stirred, reacted for 0.5h, and the obtained product solution was placed at 50°C Oven drying for 2 hours to obtain modified kaolin powder.

[0054] (3) Preparation of silanized modified kaolin suspension: Weigh 0.15 g of modified kaolin powder treated in step (2) and disperse in 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com