Space positioning and mounting construction method for large arc-shaped steel frame stand

A construction method and space positioning technology, applied in the podium and other directions, can solve the problems of difficult positioning of the inclined platform and high positioning requirements, and achieve the effect of accurately controlling the elevation of the stands, improving the flatness and verticality, and meeting the requirements of the field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

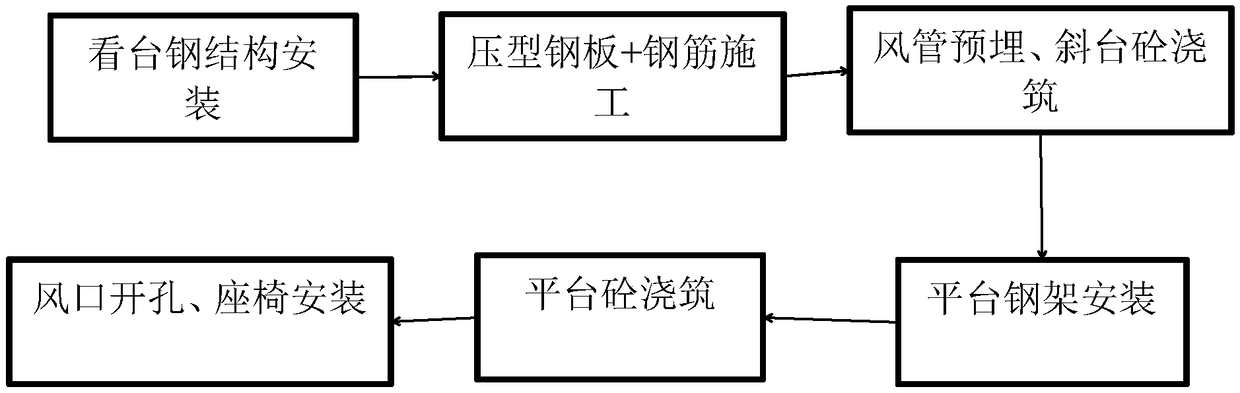

[0055] The construction method of the present embodiment, concrete steps are as follows:

[0056]S1. Stand steel structure installation

[0057] According to the characteristics of the truss in this project, most of the truss structures need to be assembled on site, so they are manufactured in parts from the factory and transported to the construction site.

[0058] The assembly sequence should be ahead of the hoisting sequence, but attention should be paid to saving the number of tire frames used for assembly, and two factors should be considered comprehensively to maximize the savings in construction costs and shorten the construction period.

[0059] Installation process: work preparation → small assembly unit → medium assembly unit → assembly acceptance → delivery and hoisting → welding → post-repair rod installation.

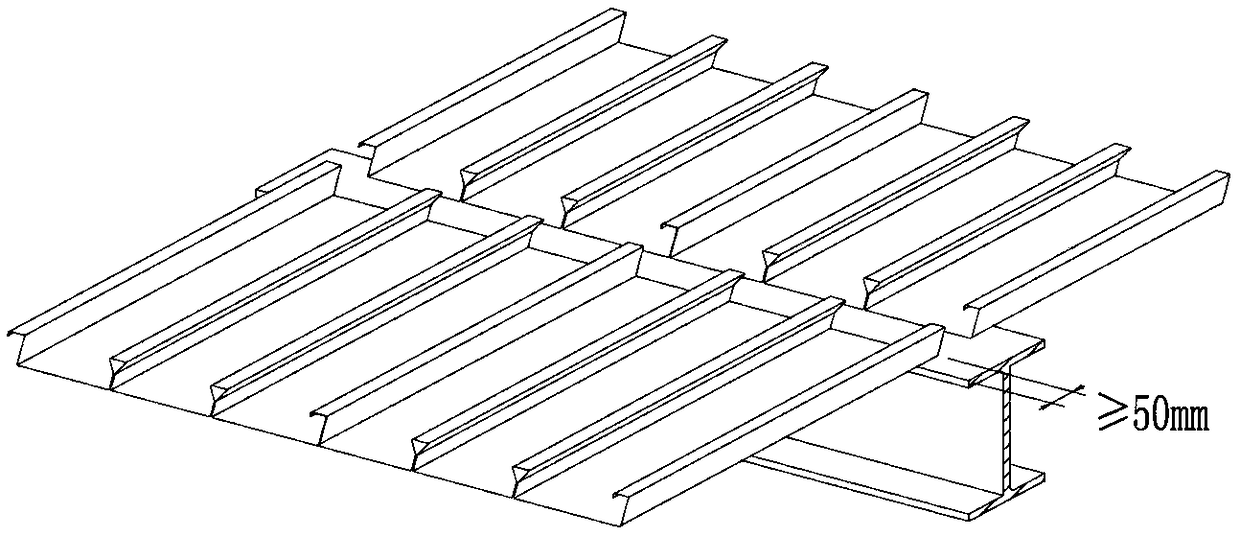

[0060] S2. Profiled steel plate installation

[0061] 1) Installation sequence

[0062] When laying profiled steel plates in the same floor plane, it is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap