A test method for high and low temperature compression response of strain rate in modified double base propellant

A double-base propellant and response testing technology, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and strength characteristics, can solve problems such as the inability to achieve propellant strain rate levels, and achieve mechanical test accuracy. , One-way time consumption is short, and the effect of ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

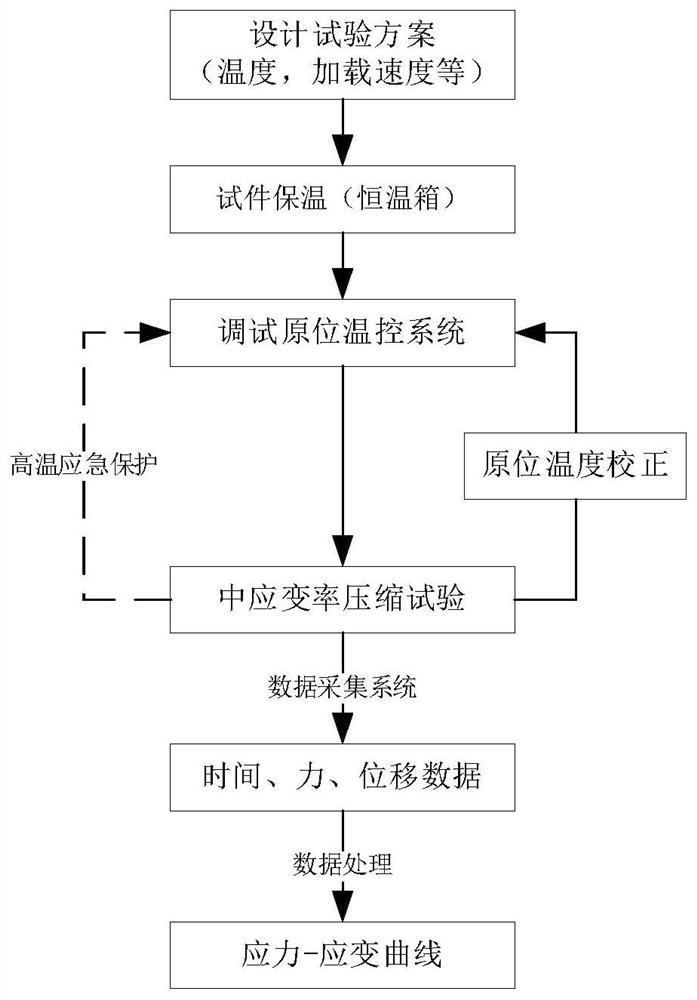

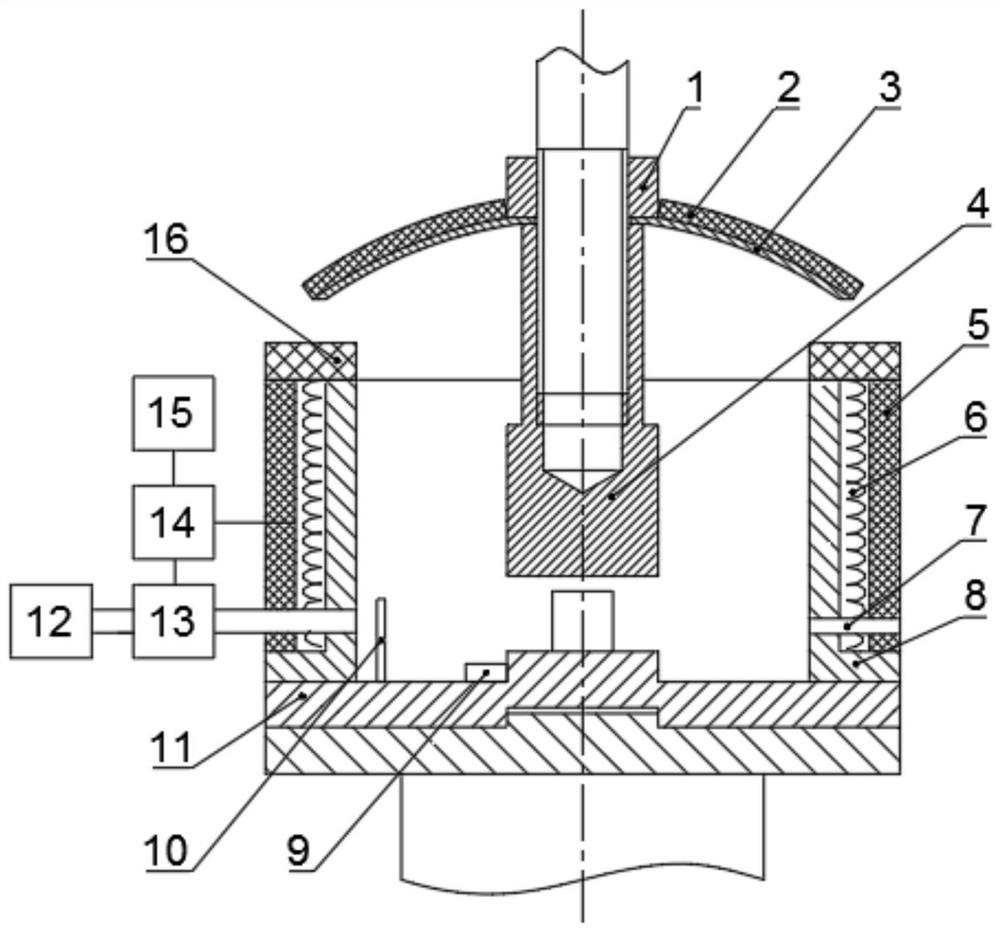

Method used

Image

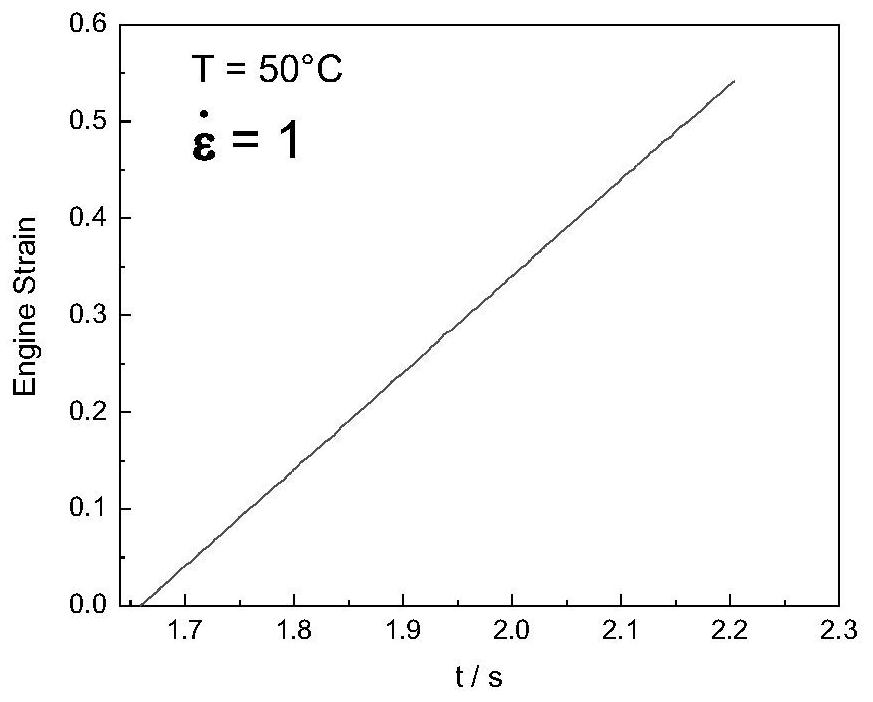

Examples

Embodiment 2

[0062] According to the test process of the above-mentioned Example 1, the temperature is set to 20°C in steps 1, 4 and 5, and the rest of the steps are the same, and it can be obtained Figure 8 The test results shown.

Embodiment 3

[0064] According to the test process of the above-mentioned Example 1, the temperature is set to -10°C in steps 1, 4 and 5, and the rest of the steps are the same, you can get Figure 9 The test results shown.

Embodiment 4

[0066] According to the test process of the above-mentioned Example 1, the temperature is set to -25°C in steps 1, 4 and 5, and the rest of the steps are the same, you can get Figure 10 The test results shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com