Logarithmic derivative analysis method based insulation aging state evaluation method of crosslinked polyethylene (XLPE) cable

A cross-linked polyethylene and cable insulation technology, applied in the direction of measuring electricity, measuring electrical variables, and testing dielectric strength, etc., can solve the problems of insignificant change rules, deviation of evaluation results, and inability to reflect the aging state of cable insulation in time. To achieve the effect of reliable evaluation results, avoiding influence, and simple and easy evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

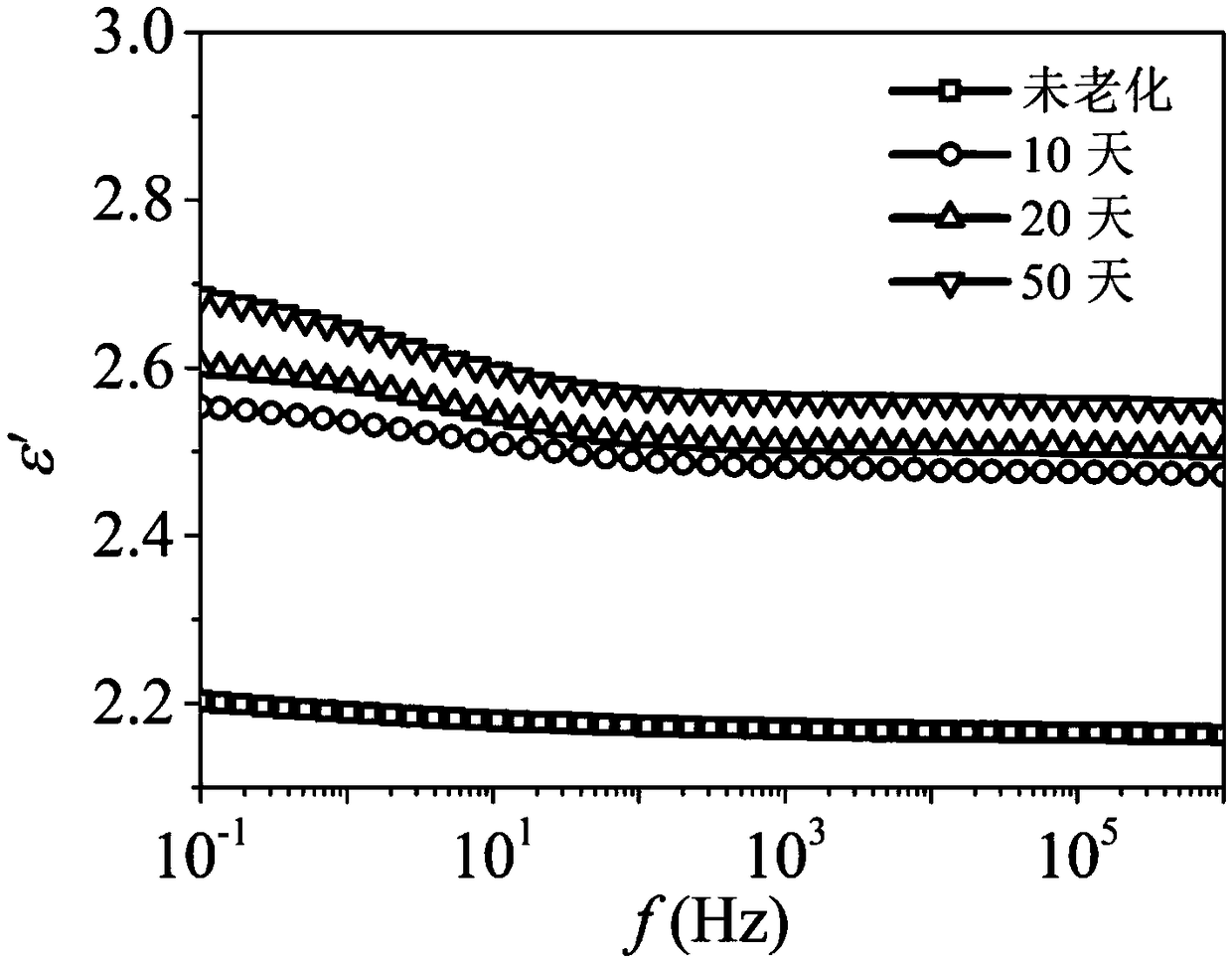

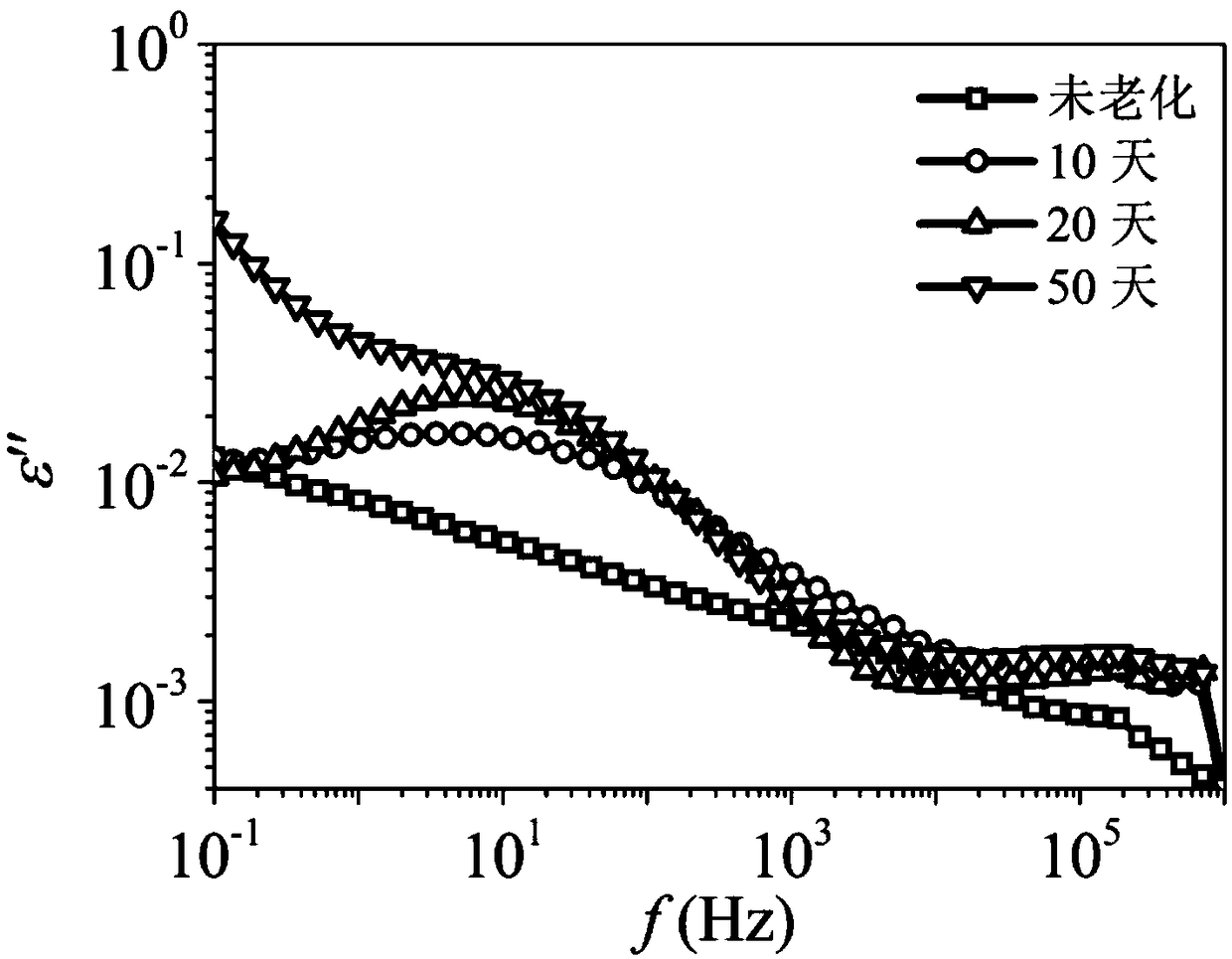

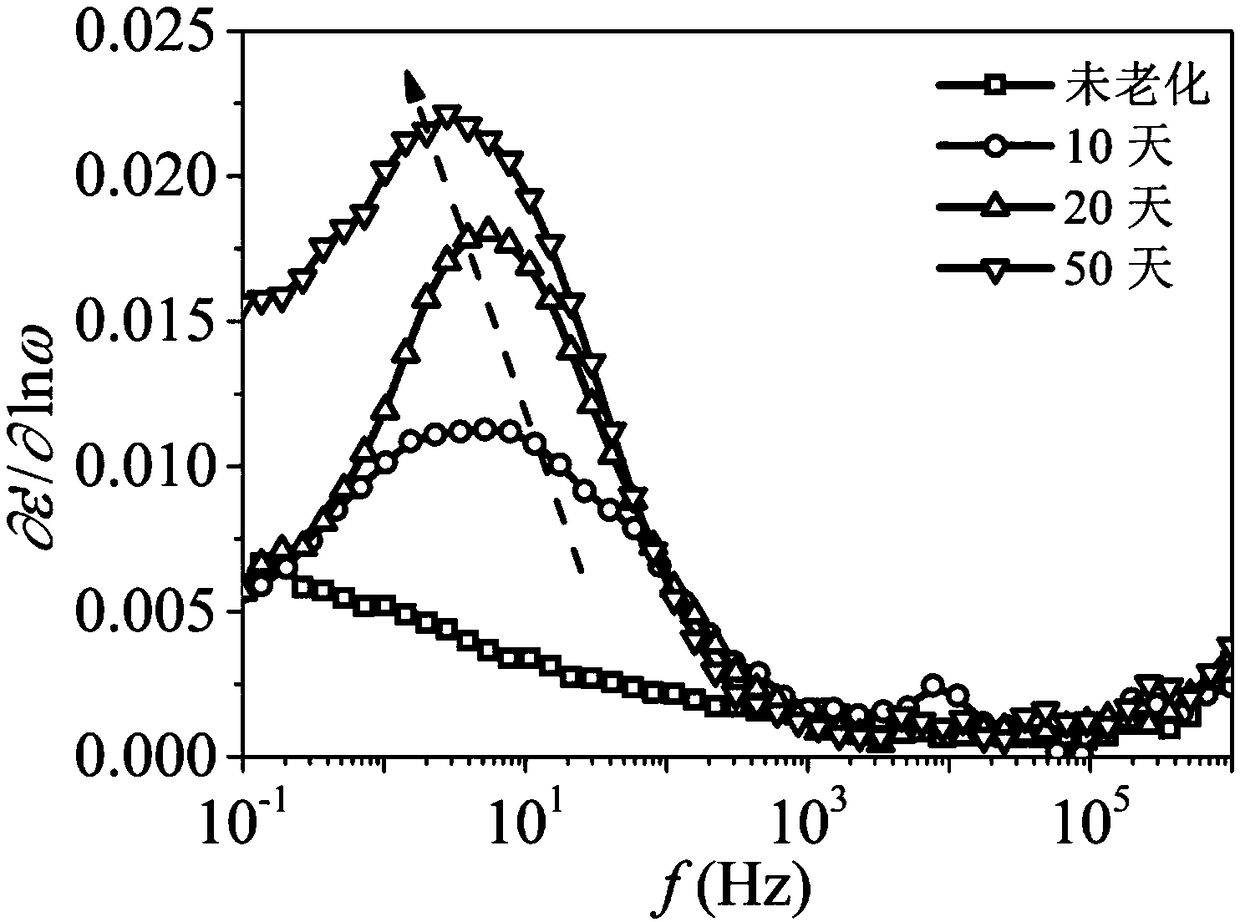

[0030] The evaluation method for the aging state of XLPE cable insulation based on the derivative analysis method includes the following steps:

[0031] 1) Sample preparation:

[0032] Slice the XLPE cable insulation to obtain a circular slice with a thickness of less than 0.3mm and a diameter of 50mm, remove surface impurities with absolute ethanol, and take one of the slices as an unaged sample;

[0033] Take the remaining 3 slices and place them in a drying oven, and conduct a heating aging experiment at 130°C. The aging treatment time of the 3 slices is 10 days, 20 days and 50 days respectively, and 3 different aging samples are obtained;

[0034] A total of four target samples (1 unaged target sample, 3 aged target samples) were obtained;

[0035] 2) Electrode fabrication: perform ion sputtering (spraying gold) on both sides of the target sample to form two metal electrodes, and the diameter of the effective electrode of the target sample is 40mm.

[0036] 3) Dielectric...

Embodiment 2

[0048] 1) Sample preparation: Slice the XLPE cable insulation to obtain a circular sample with a thickness of 0.5mm and a diameter of 40mm, remove surface impurities with absolute ethanol, take one of the slices as an unaged sample, and take the remaining slices Placed in a drying oven, the heating aging test was carried out at 150°C. The aging time was 10 days, 20 days and 50 days, and there were four target samples including the unaged samples.

[0049] 2) Electrode production: ion sputtering is performed on the front and back sides of the target sample to form two metal electrodes, and the diameter of the circular effective electrode is 30 mm.

[0050] 3) Dielectric spectrum test: place the sample in the dielectric spectrum tester, set the test temperature, frequency range and voltage, start the dielectric spectrum tester, measure the frequency characteristics of the complex dielectric constant of the XLPE cable insulation, and measure The real part of the permittivity ε' a...

Embodiment 3

[0059] 1) Sample preparation: Slice the XLPE cable insulation to obtain a circular sample with a thickness of 0.2mm and a diameter of 30mm, remove surface impurities with absolute ethanol, take one slice as an unaged sample, and take the remaining slices Placed in a drying oven, the heat aging test was carried out at 100°C. The aging time was 10 days, 20 days and 50 days, and there were four target samples including the unaged samples.

[0060] 2) Electrode production: ion sputtering is performed on the front and back sides of the target sample to form two metal electrodes, and the diameter of the circular effective electrode is 20mm;

[0061] 3) Dielectric spectrum test: place the sample in the dielectric spectrum tester, set the test temperature, frequency range and voltage, start the dielectric spectrum tester, and measure the real part ε' and the imaginary part of the dielectric constant ε”; measure the frequency characteristics of the complex dielectric constant of the XL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com